Hollow bolt ball welding tool

A technology for welding tooling and hollow bolts, used in welding equipment, welding accessories, manufacturing tools, etc., can solve the problems of inconvenient butt joint and welding, unstable clamping and inconvenient clamping of hollow hemisphere welding, and achieve the convenience of surrounding welding, Simple structure, the effect of reducing trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

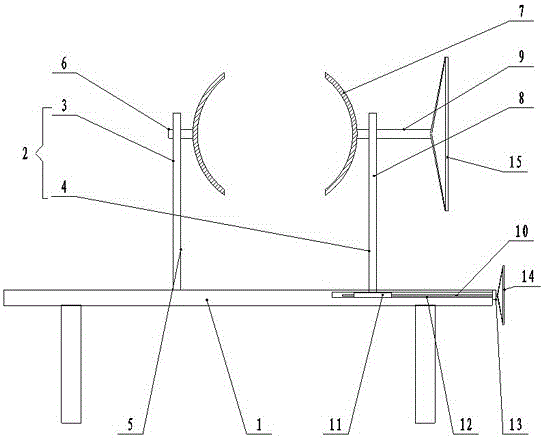

[0025] Such as figure 1 As shown, a hollow bolt ball welding tool of the present invention includes a welding table 1 and a welding ball clamping assembly 2, the welding table 1 is supported by legs under the cast iron panel, and the welding ball clamping assembly 2 includes a welding ball clamping and fixing frame 3 and the welding ball clamping mobile frame 4; the welding ball clamping fixed frame 3 includes a fixed frame 5, a rotating shaft 6 and a ball cap 7, the fixed frame 5 is fixedly arranged on the welding table 1, and the inner end of the rotating shaft 6 is provided with a clamping welding The spherical cap 7 of the ball, the outer end of the rotating shaft 6 is horizontally provided with a fixed frame 5 through the bearing; block 11, the welding table 1 is provided with a chute 12 matching with the slider 11, the slider 11 is provided with a thread hole, the end of the chute 12 is provided with a screw seat 13, and the screw 10 passes through the screw seat 1 Inst...

Embodiment 2

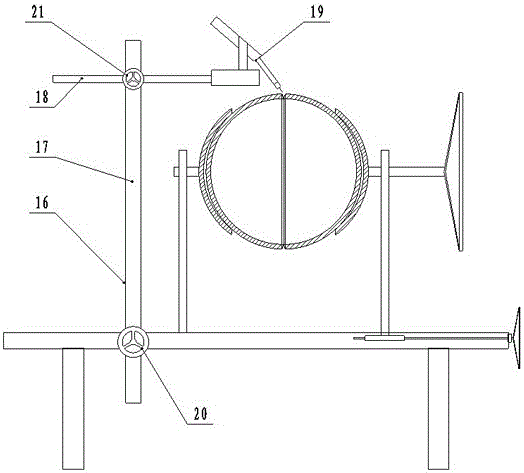

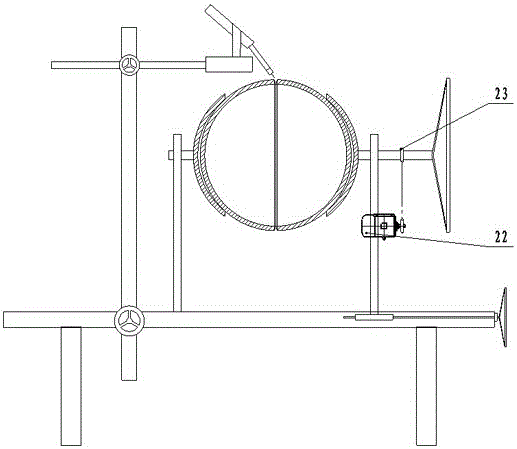

[0029] Such as Figure 1-2 As shown, a hollow bolt ball welding tool of the present invention, on the basis of Embodiment 1, in order to improve the welding quality and reduce the labor intensity of workers, a welding torch bracket 16 is arranged on the welding table 1, and the welding torch bracket 16 includes an adjustable lifting column 17 And adjust the horizontal moving cross bar 18, adjust the lifting column 17 lower ends to be arranged on the welding table 1, adjust the lifting column 1 upper end to be provided with the adjustment horizontal moving cross bar 18, adjust the horizontal moving cross bar 18 ends to be equipped with welding torch 19. By arranging the welding torch bracket 16 and the welding torch 19 on the welding table 1, it is possible to eliminate the need for workers to hold the welding torch 19 for welding, and to control the welding torch 19 through the mechanical arm, so that the quality and efficiency of welding are greatly improved. Welding torch 19...

Embodiment 3

[0031] Such as Figure 1-2 As shown, a hollow bolt ball welding tooling of the present invention, on the basis of Embodiment 1, the adjusting lifting column 17 is inserted in the mounting hole provided on the welding table 1, and the mounting hole is provided with a fastening and adjusting lifting column 17 Adjustment bolt 20. The adjustment horizontal moving cross bar 18 is inserted in the adjusting hole provided at the upper end of the adjusting lifting column 17, and the fastening bolt 21 for fastening and adjusting the horizontal moving cross bar 18 is arranged on the adjusting hole. The welding torch bracket 16 adopts an adjustable structure, and the position of the welding torch 19 can be adjusted to facilitate welding with welding balls, so as to adapt to welding balls of various sizes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com