Inspection Robot Mechanism of Hugging Mine Hoist Based on Electromagnetic Chuck

A technology for inspection robots and electromagnetic chucks, which is applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of damage to the paint protection layer, heavy robot weight, and high energy consumption, and achieve reduced volume and weight, simple and light structure , the effect of reducing power requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

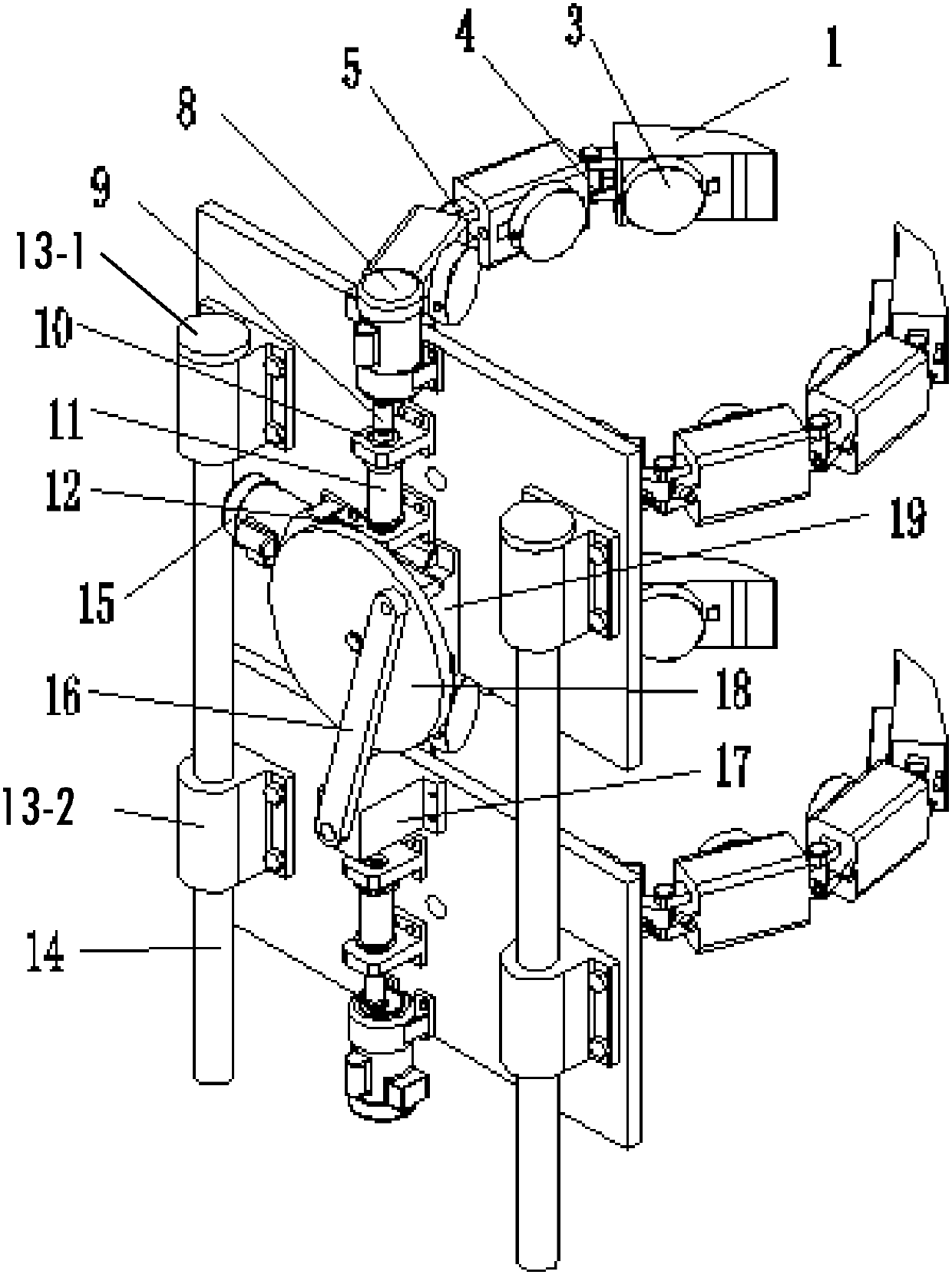

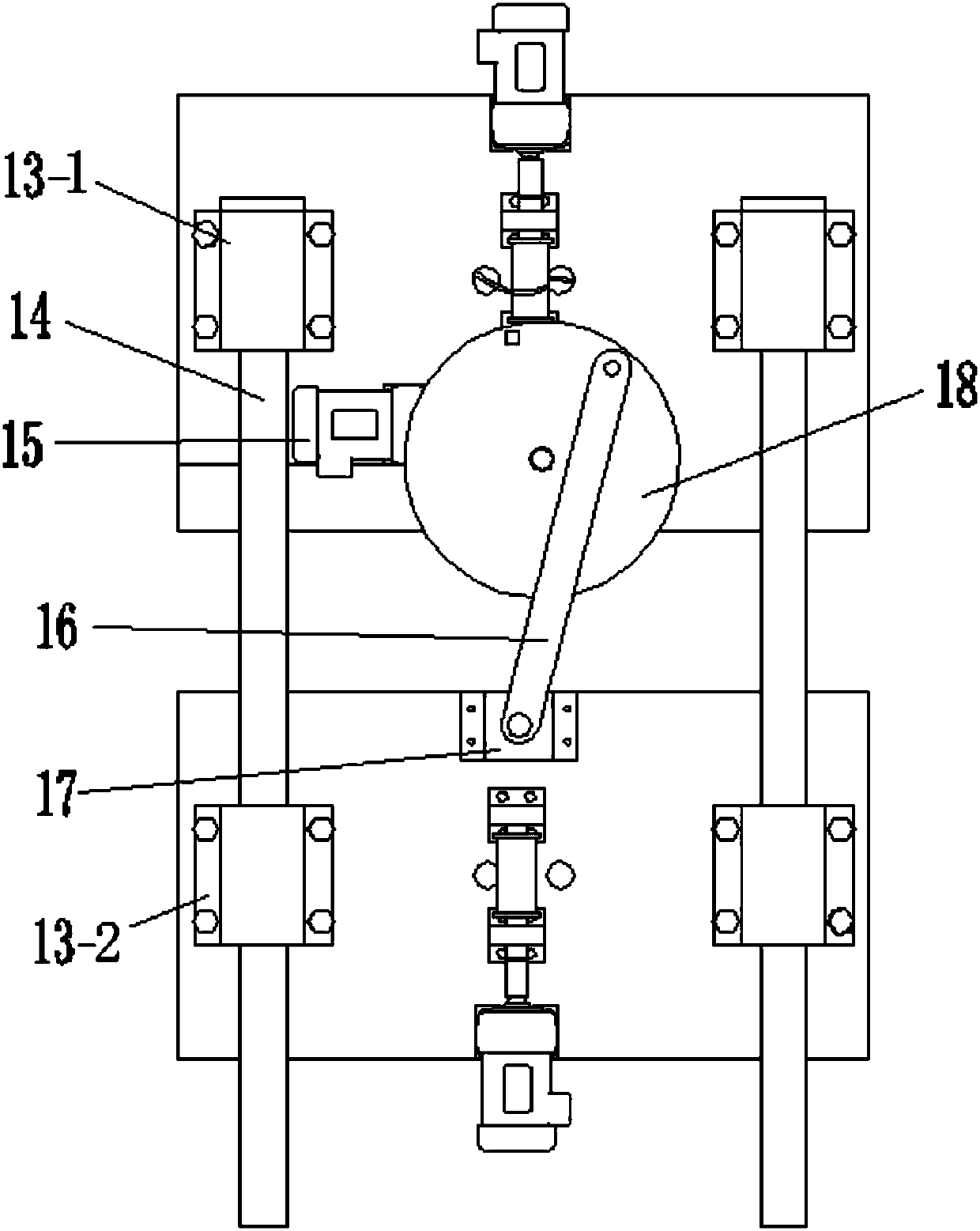

[0023] An electromagnetic suction cup-based hugging coal mine hoist inspection robot mechanism, which is divided into two upper and lower manipulator parts with the same structure, and the two manipulator parts are connected by a crank slider mechanism and a slider slider mechanism. Alternately hold the hoist column tightly, and at the same time combine the crank slider mechanism and the slider slider mechanism to realize the alternate rise of the two manipulator parts so as to realize the overall movement of the robot.

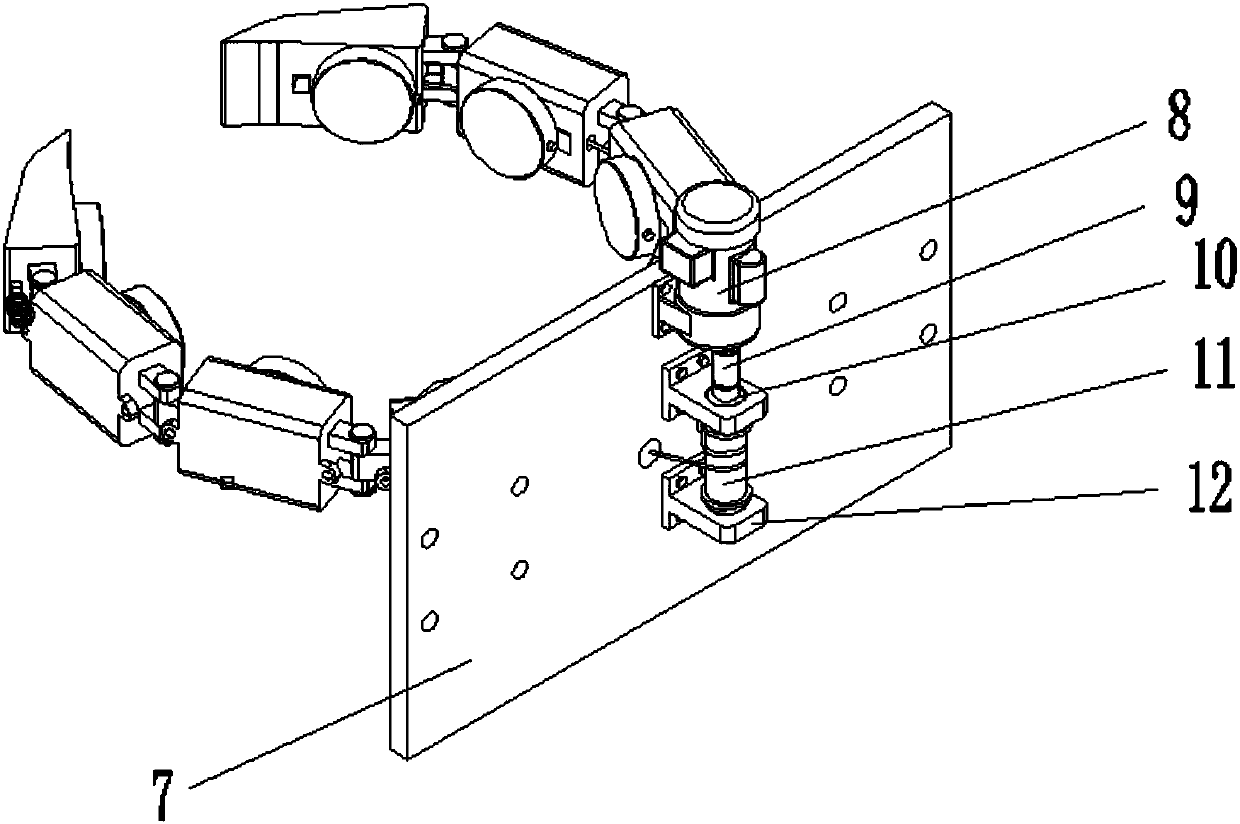

[0024] See attached image 3 And attached Figure 4 , the two manipulator parts respectively include two left-right symmetrical mechanical claws, and each mechanical claw includes a fingertip joint 1 and three intermediate joints 6 (the overall fingertip joints are approximately triangular, and the fingertips of the fingertip jo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com