A non-linkage transfer mechanism, its transfer method and vamp bonding device

A non-linkage, transfer technology, applied in the direction of transportation and packaging, conveyor objects, etc., to solve the dilemma, improve product quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

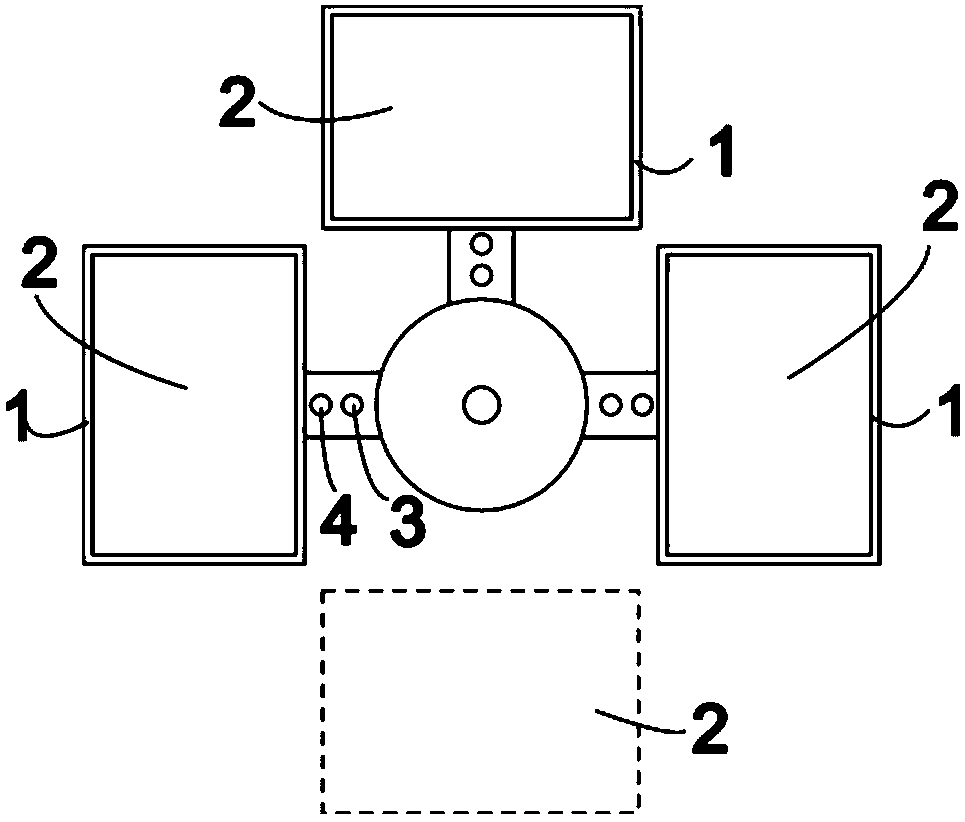

[0047] see Figure 1-Figure 3 As shown, a non-linkage transfer mechanism includes a controller (not shown) and three non-linkage carriers 1, each carrier 1 corresponds to a station 2, which are respectively distributed in different positions in the circumferential direction, and There is a fourth station 2 without carrier. The controller controls each carrier to rotate independently, and can make 1, 2 or 3 carriers shift from their station to another station.

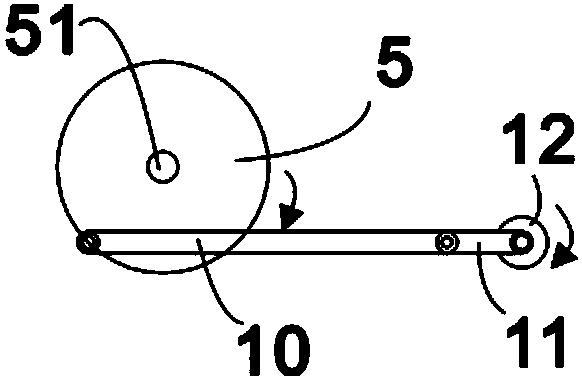

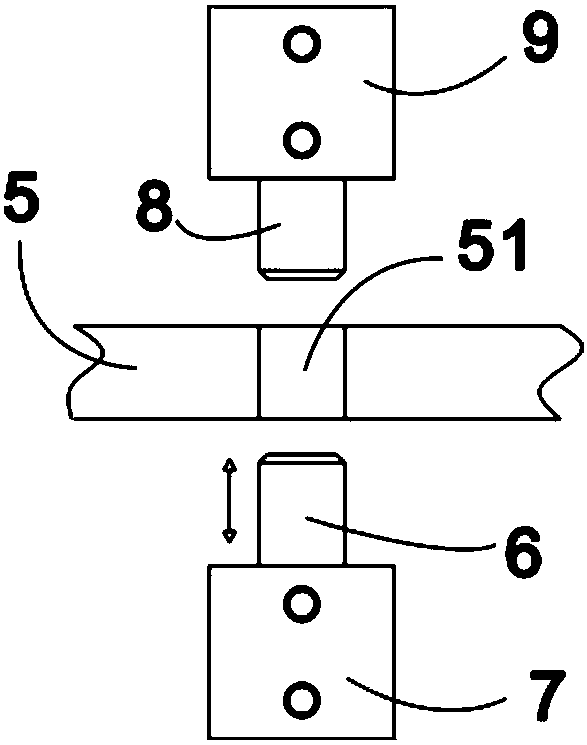

[0048] The carrier 1 can be a template bracket 1 or a transfer platform. Taking template bracket 1 as an example, three template brackets are set, and each template bracket 1 is provided with transfer pin holes 3, such as figure 1 As shown, correspondingly matched with it, there is also a transfer tray 5 driven by a motor and a first positioning mechanism, and the first positioning mechanism will accurately position the template bracket or transfer platform transferred to the station at the station superior. The fir...

Embodiment 2

[0062] With reference to embodiment 1, different from embodiment 1, see Figure 4 As shown, the template bracket or the transfer platform is provided with a second positioning mechanism, and the second positioning mechanism is provided with a positioning wheel 13 and a positioning groove 14 correspondingly matched with the positioning wheel 13, and the positioning groove 14 can be attached to the rack. The first positioning mechanism can be automatically released by the positioning pin cylinder, and the second positioning mechanism can be passively released with the rotation of the template bracket or the transfer platform.

[0063] Of course, this embodiment can also be modified as follows: the positioning wheel and the positioning groove are reversed: the positioning groove is arranged on the template bracket or the transfer platform, and the positioning wheel is arranged on the frame.

Embodiment 3

[0065] With reference to embodiment 1, different from embodiment 1, see Figure 5 As shown, each carrier is independently connected to the same circular track 15 , and the controller controls each carrier to independently rotate along the circular track 15 . Both the transfer tray and the template bracket run along the circular track.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com