Crane mounted at sea

A crane and jib technology, which is applied in the field of cranes for offshore installation operations, can solve the problems of inability to rent floating cranes, unable to meet the requirements of offshore installation and hoisting operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

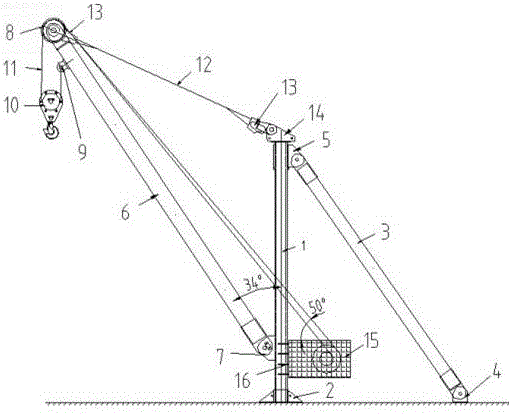

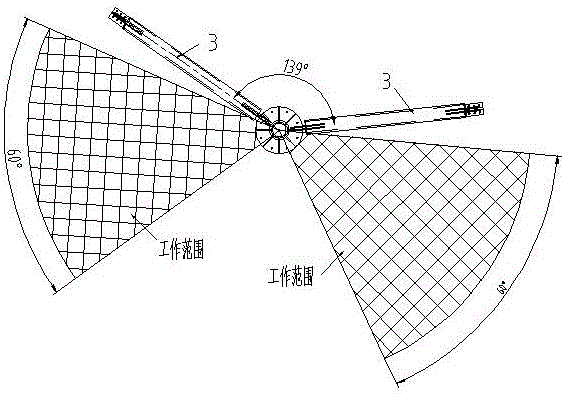

[0011] combine figure 1 and 2 It can be seen that a crane installed at sea includes two parts: a support unit and a lifting unit: the support unit includes a main support 1, and the main support 1 is respectively connected to the main support base 2, the pneumatic winch base 16, the boom base 7, and the auxiliary support from bottom to top. Connector 5, luffing wire rope base 14.

[0012] Boom 6 connects boom base 7, wire rope fixer 9, boom pulley 8 respectively from bottom to top. The boom 6 is connected to the luffing wire rope base 14 on the main support 1 through the boom pulley 8, the luffing wire rope connector 13, and the luffing wire rope group 12 to form a boom support mechanism.

[0013] The lower end of the auxiliary support 3 is connected to the deck through the auxiliary support base 4, and the upper end is connected to the main support 1 through the auxiliary support connector 5 to form a main support mechanism. The lifting unit includes an air winch 15 connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com