A hardness tester

A technology of hardness tester and calibrator, which can be used in instruments, scientific instruments, strength characteristics, etc., and can solve the problems of test result error and longitudinal displacement of hardness tester.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

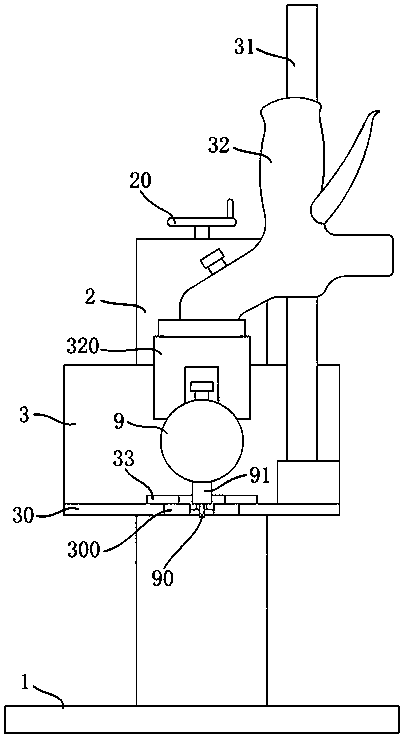

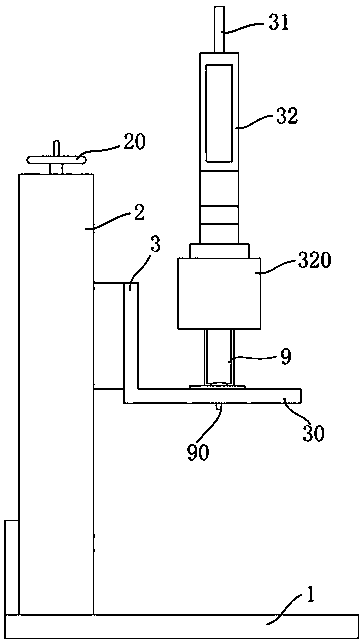

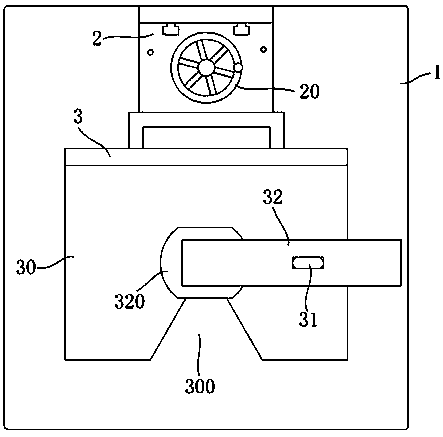

[0023] Embodiment one of the hardness tester tester of the present invention: as Figure 1-7 As shown, including a base 1, the base 1 is provided with a vertically arranged screw nut mechanism 2, wherein the screw is fixed in the vertical direction, and the nut threaded on the screw can move up and down when the screw rotates. The upper end of the leading screw nut mechanism 2 is provided with a rotating handle 20 for rotating the leading screw.

[0024] A durometer holder 3 is fixedly connected to the nut, and the durometer holder 3 can guide and move with the nut in the up and down direction. The hardness tester holder 3 includes an L-shaped plate with horizontal and vertical sides. The horizontal edge of the L-shaped plate, that is, the horizontal fixed plate 30, is detachably equipped with a spacer 33. The spacer 33 is provided with an upper support for the hardness tester 9 In this way, when testing different types or shapes of hardness testers, it is enough to separatel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com