High-precision contact thermal resistance measuring device under vacuum condition

A technology of contact thermal resistance and vacuum conditions, applied in the field of high-precision contact thermal resistance measurement devices, to achieve the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

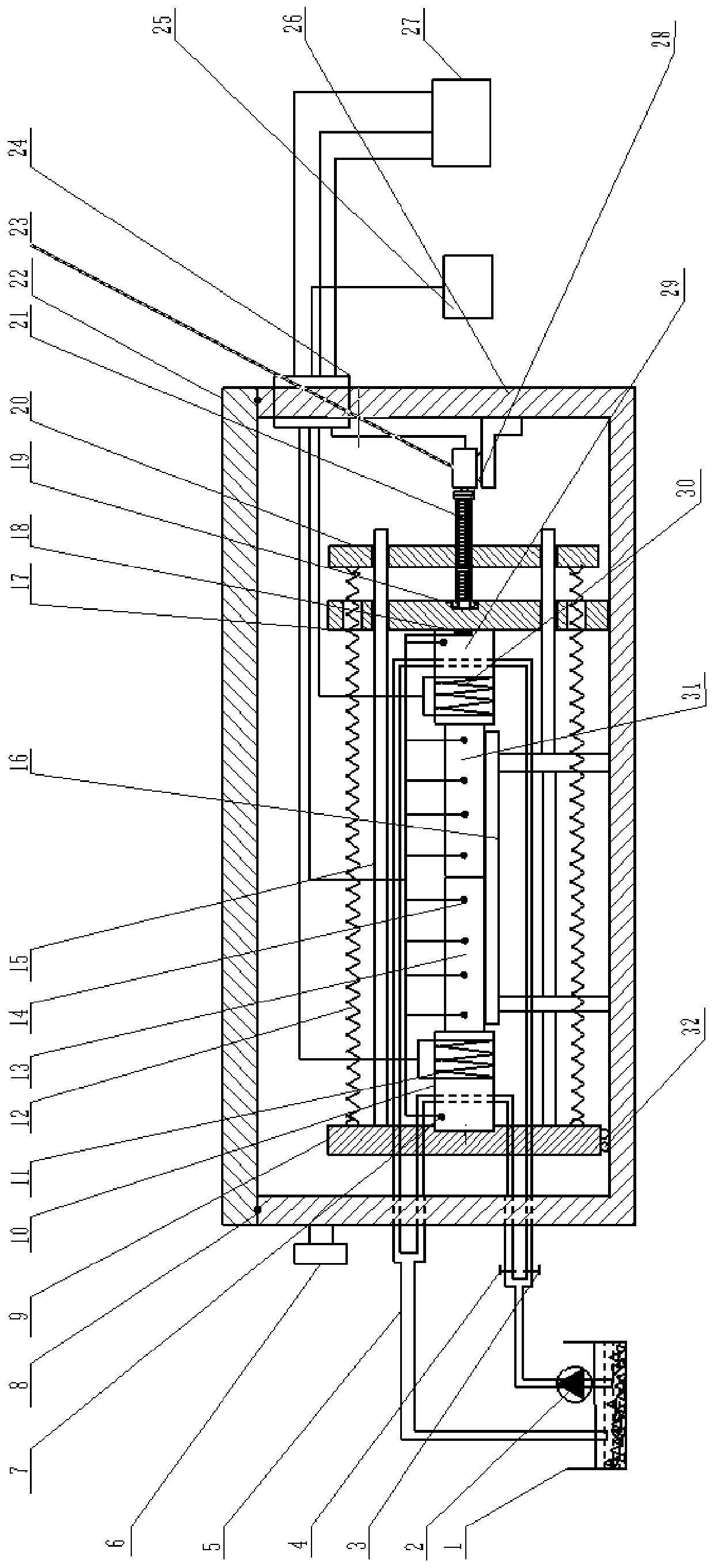

[0016] Such as figure 1 , a high-precision contact thermal resistance measurement device under vacuum conditions, which includes a vacuum chamber, a left moving plate 9, a spring 12, a guide rod 15, a left temperature control block 10, a right temperature control block 29, and a first DUT 13. The second DUT 31, the DUT support frame 16, the right fixed plate 17 and the right moving plate 20, the vacuum chamber includes the vacuum lower cavity 26 and the vacuum cavity upper cover 22, the left moving plate 9, the spring 12. Guide rod 15, left temperature control block 10, right temperature control block 29, first DUT 13, second DUT 31, DUT support frame 16, right fixed plate 17, right moving plate 20 They are all located inside the vacuum chamber, the DUT supporting frame 16 is fixed at the bottom of the cavity under vacuum, and the first DUT 13 and the second DUT 31 are pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com