A wire forming device

A wire rod and forming wheel technology, applied in the field of wire rod forming devices, can solve problems such as fatigue life reduction and wire rod surface damage, and achieve the effect of large meshing depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

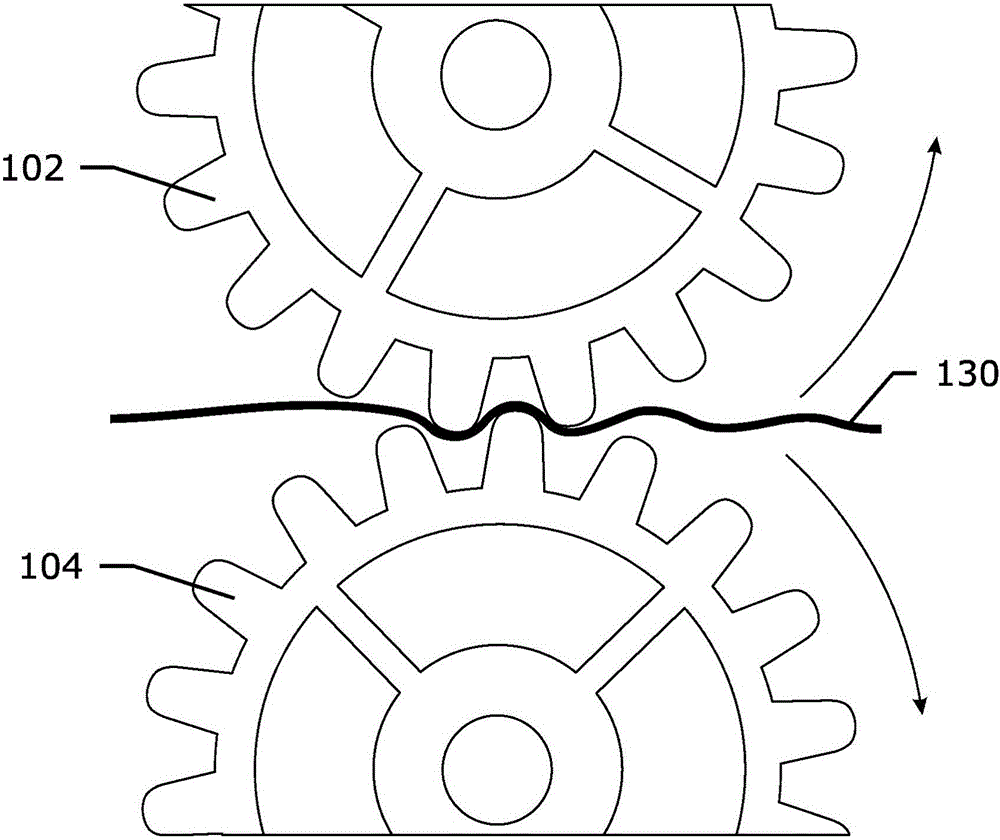

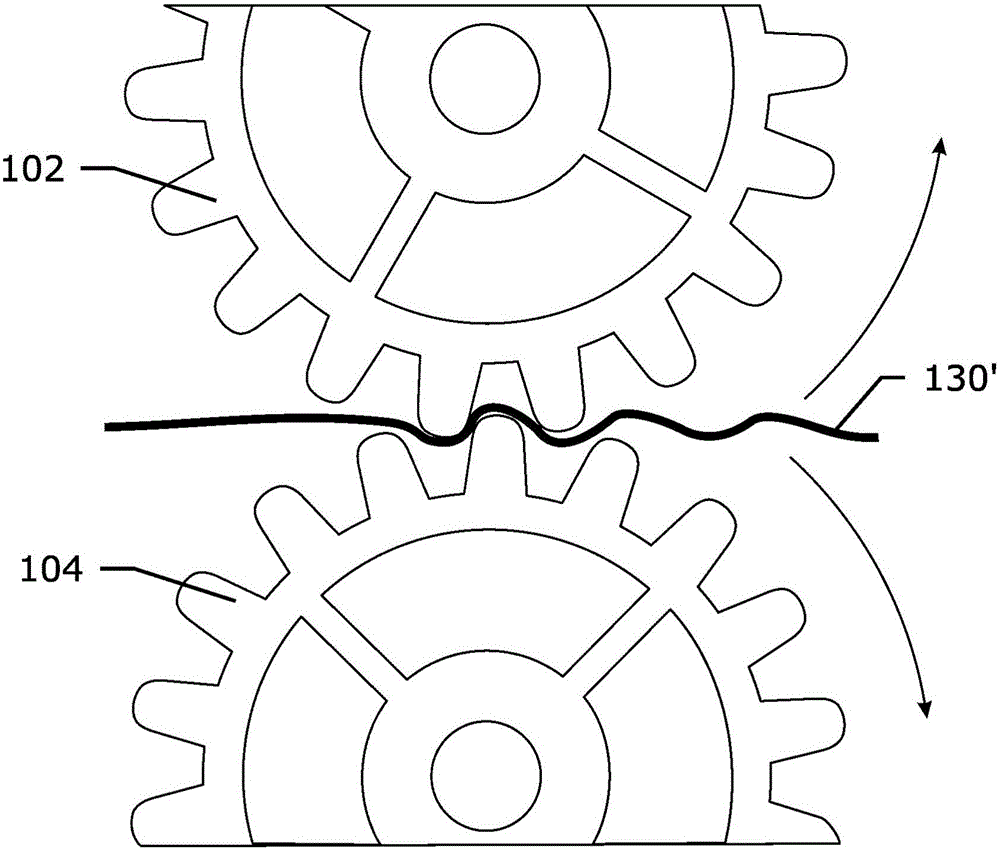

[0068] image 3 A first preferred embodiment of the inventive wire shaping device 300 is shown. It comprises a holder 310 in which deformation wheels 302 and 304 are mounted. Deformation wheels 302 and 304 are mounted on shafts 322 and 324, respectively. Bearings (not shown) for the deforming wheels are mounted in bearing housings 332, 332' and 334, 334' between the shafts 322, 324 and the holder 310, respectively. The top shaft 322 can be lowered or raised by means of set screws 318, 318', thereby adjusting the gap between the deformation wheels. A coiled wire 330' exists between the deformation wheels. Two slots 320, 320' are provided in the holder 310 to allow the top deformation axle to move parallel to the lower deformation axle.

[0069] The difference with prior art crimpers is the presence of a synchronous coupling coupling the rotational movement of the first and second deforming wheels. In this particular embodiment, the synchronous coupling takes the form of tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com