Large-flow combined linear screw pump

A technology of screw pump and high flow, which is applied in the direction of pumps, rotary piston pumps, liquid fuel engines, etc., and can solve problems such as increased sealing difficulty, loud noise, and reduced infusion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

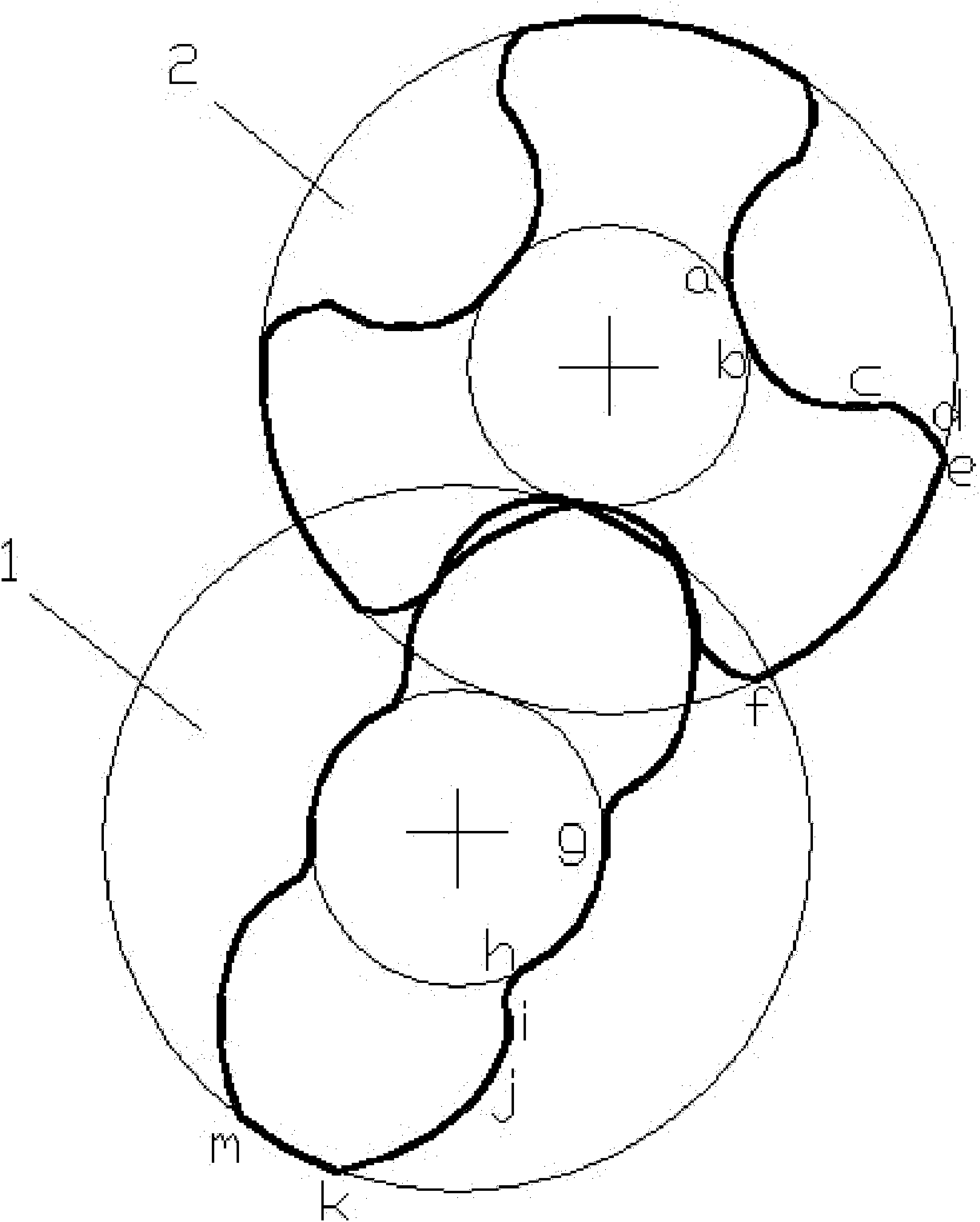

[0050] The accompanying drawing is a structural schematic diagram of the present invention, as shown in the figure: the large-flow combined linear screw pump of this embodiment includes a driving screw 1 and a driven screw 2 that are engaged with each other, and the driving screw 1 and the driven screw 2 are The radius of the top circle is greater than twice the radius of the root circle;

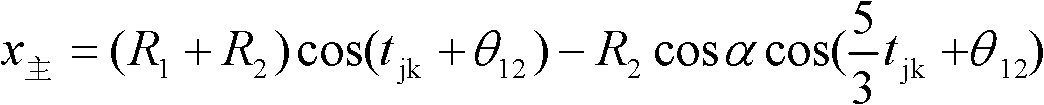

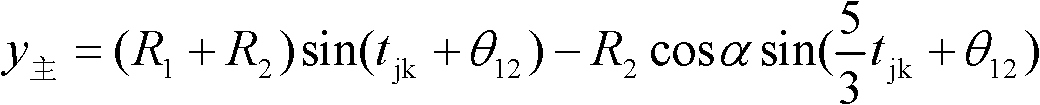

[0051] The tooth profile line of the radial section of the driving screw 1 is arc segment hi, involute segment ij and cycloid segment jk in turn from the tooth root to the tooth top;

[0052]The tooth profile line of the radial section of the driven screw 2 is the cycloid segment bc, the involute segment cd and the arc segment de from the tooth root to the tooth top;

[0053] As shown in the figure, on the driving screw, the root arc gj is connected with the arc segment hi, and the addendum arc km is connected with the cycloid segment jk, forming the entire tooth shape of the radial section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com