UV (ultraviolet) solidifying device

A technology of curing device and traction device, which is applied in the direction of surface coating liquid device, pretreatment surface, coating, etc., which can solve the problems of workers' physical injury, light pollution, insufficient curing rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

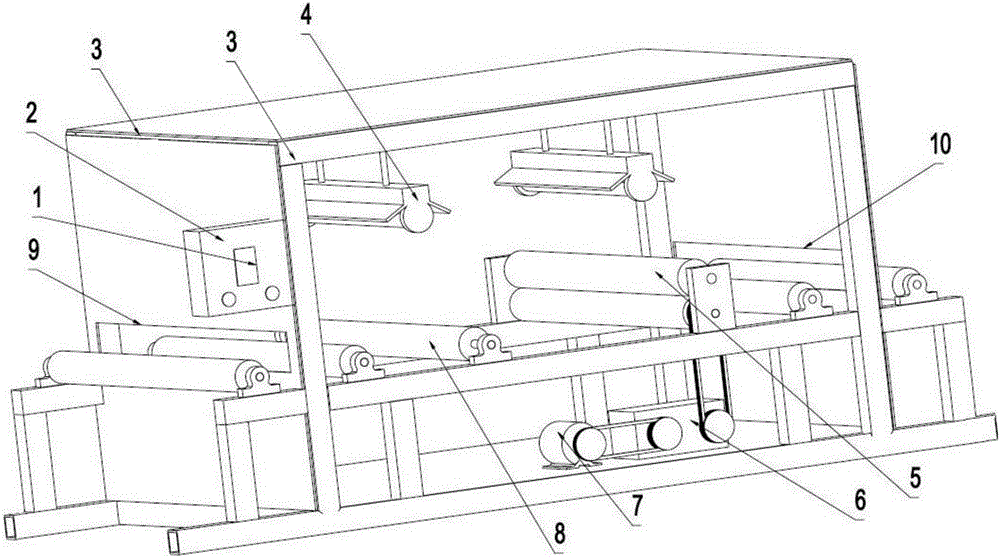

[0019] The preferred embodiments of the present invention are given below in conjunction with the drawings and descriptions of the drawings to describe the technical solution of the present invention in detail.

[0020] A UV curing device includes a bracket 3 for placing a UV lamp 4, and a traction device 5 is arranged in the middle of the bracket 3. The traction device 5 is composed of a pair of upper and lower traction rollers that rotate in opposite directions. The upper and lower traction rollers are rubber rollers or Plastic roller, the surface of the upper and lower traction rollers is provided with herringbone patterns to increase friction, the gap between the upper and lower traction rollers forms a film traction opening, and the size of the gap between the upper and lower traction rollers matches the film thickness, An adjustment device for adjusting its installation height is set on the upper traction roller; two UV lamps 4 are installed on the top of the bracket 3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com