Notebook computer keyboard substrate and processing technique thereof

A notebook computer and processing technology, applied in the direction of circuits, electric switches, electrical components, etc., can solve the problems of low production efficiency and product yield, weak spray coating adhesion, low product yield, etc., to ensure product quality and product yield, improve product yield, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with embodiment.

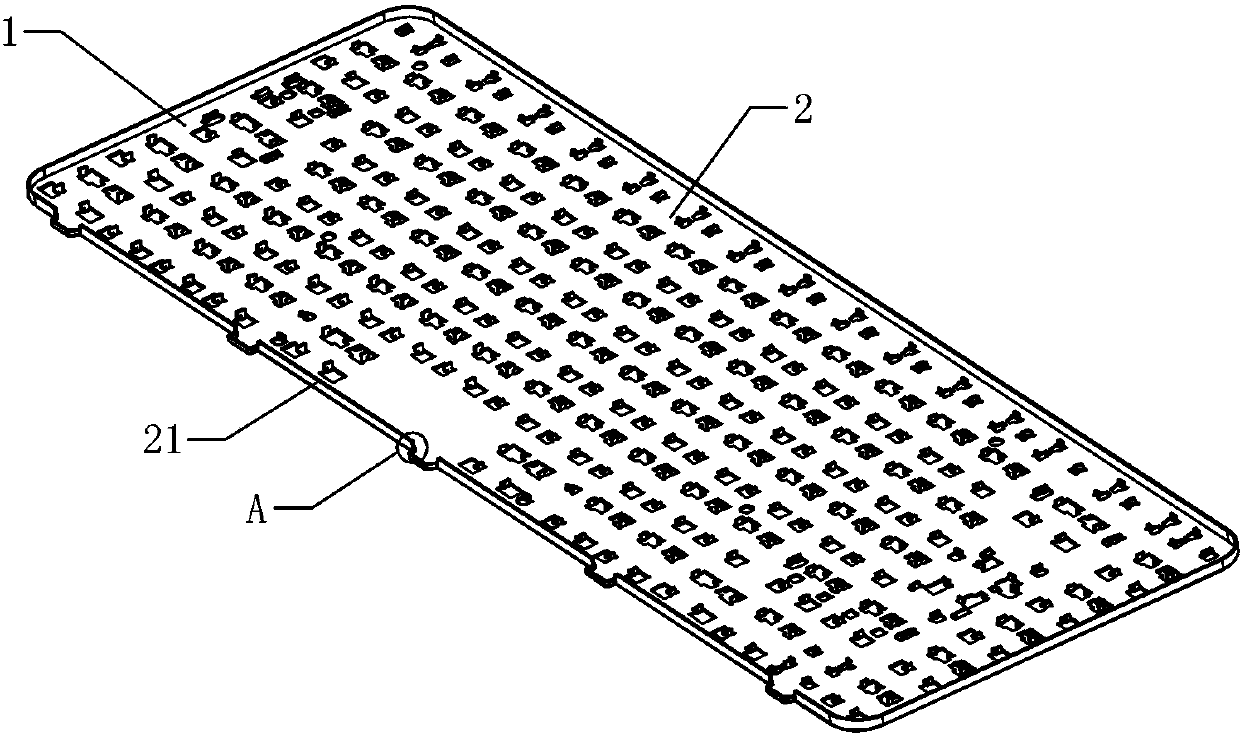

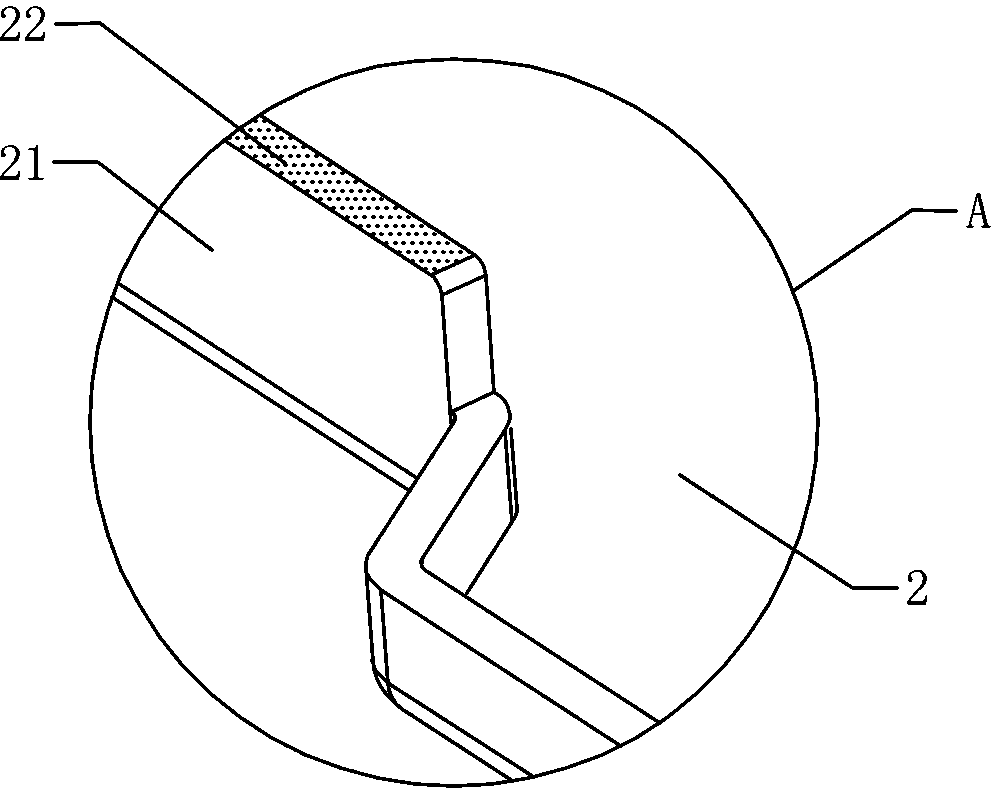

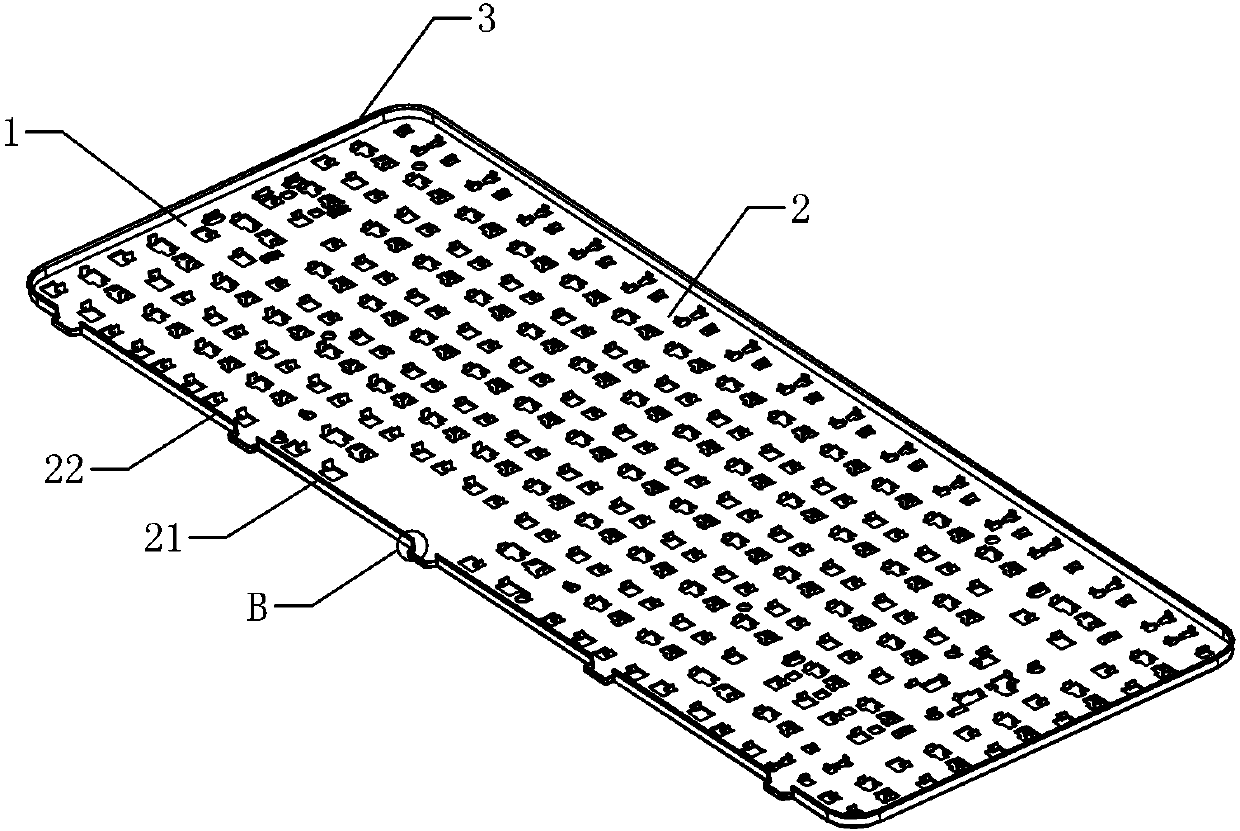

[0037] Such as image 3 , Figure 4 As shown, a keyboard substrate 1 of a notebook computer, its periphery is bent vertically upwards to form an accommodating groove 2. The groove wall 21 of the storage tank 2 is provided with a bending part 3, so that the cut surface 22 of the groove wall 21 of the accommodation groove 2 faces the horizontal direction, and the cut surface 22 of the groove wall 21 of the accommodation groove 2 is avoided to be directly exposed outside, thereby eliminating the need for Then, a spray coating is applied to the cut surface 22 of the groove wall 21 of the accommodating groove 2, which is easy to process, improves product yield, and makes the overall appearance of the keyboard more beautiful.

[0038] Wherein, the keyboard substrate 1 is rectangular, and the four sides of the keyboard substrate 1 are provided with groove walls 21 of the accommodating gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com