Method for detecting position of blocked point of pipeline

A point position and pipeline technology, which is applied in the field of pigging equipment, can solve the problems of difficult maintenance and repair work, and achieve the effect of reliable guarantee and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

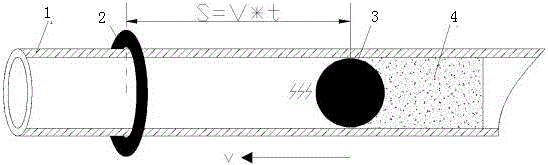

[0019] The underground crude oil pipeline between the oil field well site and the station often freezes and blocks in winter. At present, it is judged by human experience, which has a high error rate and is time-consuming and laborious. In order to overcome the above problems, the present invention provides figure 1 Shown is a method for detecting the position of the pipeline blockage point. The present invention accurately judges the position of the blockage point by putting a self-vibrating pig in the pipeline, and solves the needless workload caused by manual judgment errors that make maintenance and emergency repairs difficult. For problems with difficult work, ensure that faults are dealt with quickly in the shortest time and improve production efficiency.

[0020] A method for detecting the position of a pipeline blockage point, the specific steps are:

[0021] Step 1. Install a signal receiver 2 on the exposed part of the oil pipeline 1 on the well site, which can dete...

Embodiment 2

[0027] Based on Example 1, the distance S in Step 3 in this example is based on the known propagation velocity V of the sound wave in the steel medium and the time difference between the pig 3 sending out the signal and the signal receiver 2 receiving the signal Δ T, the position of the pig is obtained from S=V·△T, that is, the position of the internal blockage point of the pipeline.

[0028] One end of the oil pipeline 1 is connected to a signal receiver 2, and the signal receiver 2 is located on the part of the oil pipeline 1 exposed to the surface; the pig 3 is located in the oil pipeline 1.

[0029] The signal receiver 2 is a ring signal receiver.

[0030] One end of the oil pipeline 1 is connected with a signal receiver 2, and the signal receiver 2 is located on the part of the oil pipeline 1 exposed to the surface; the pig 3 is located in the oil pipeline 1.

[0031] The signal receiver 2 is a ring signal receiver. The ring signal receiver can receive the signal sent b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com