Bottle preform carrier based on spring fastening, and bottle blowing machine

A spring fastening and bottle blowing machine technology, which is applied in the field of blow molding machines and preform carriers, can solve the problems of unstable fixing and affecting bottle production, and achieve the effects of increasing process difficulty, simple structure, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

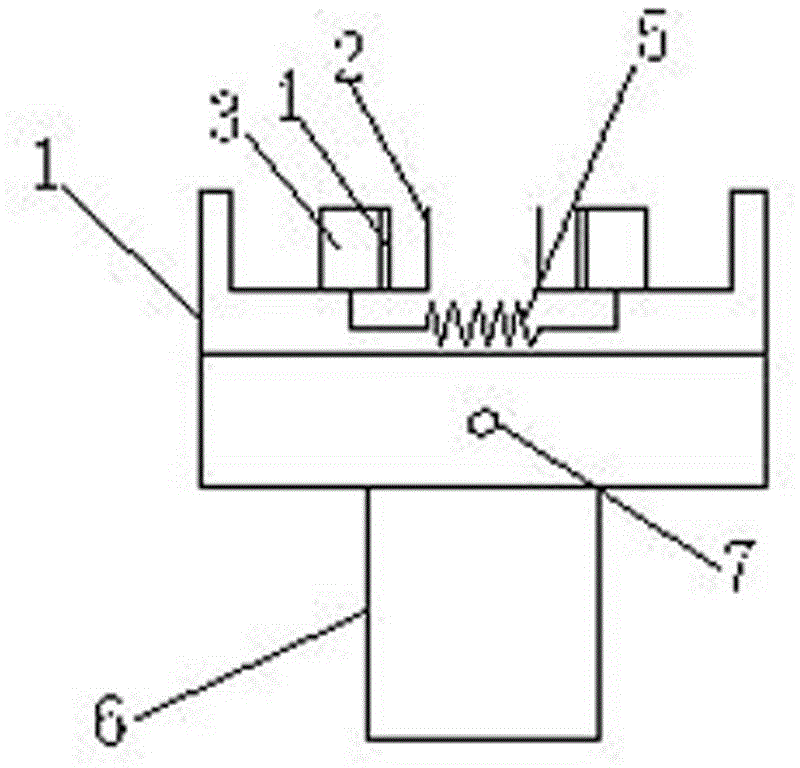

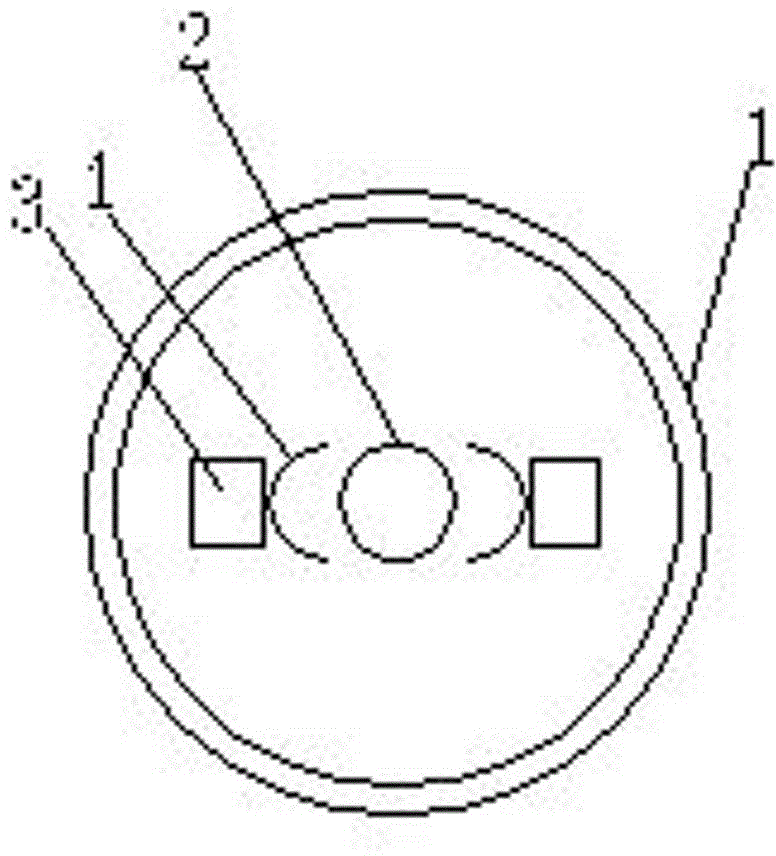

[0016] Embodiments of the present invention provide a preform carrier based on spring fastening, such as figure 1 , 2 As shown, the top of the preform carrier 1 is provided with a preform fixing column 2, and the left and right sides of the preform fixing column 2 are respectively provided with sliders 3, and the slider 3 is close to the side of the preform fixing column 2. One side is provided with an arc-shaped stopper 4 that fits in shape with the preform fixing column 2 , and a spring 5 is provided under the preform fixing column 2 , and both sides of the spring 5 are respectively connected with the slider 3 .

[0017] The fixed column 6 at the bottom of the preform carrier 1 is connected to the conveyor belt.

[0018] The air inlet 7 provided on the side of the preform carrier 1 communicates with the air supply unit of the bottle blowi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com