Spicy strip blank cooling and sectioning device

A cooling device and cutting technology, applied in metal processing and other directions, can solve problems such as the influence of the quality of the spicy strips, the sticking of the spicy strips, and the inability to adjust the length of the spicy strips.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is further illustrated by the following examples.

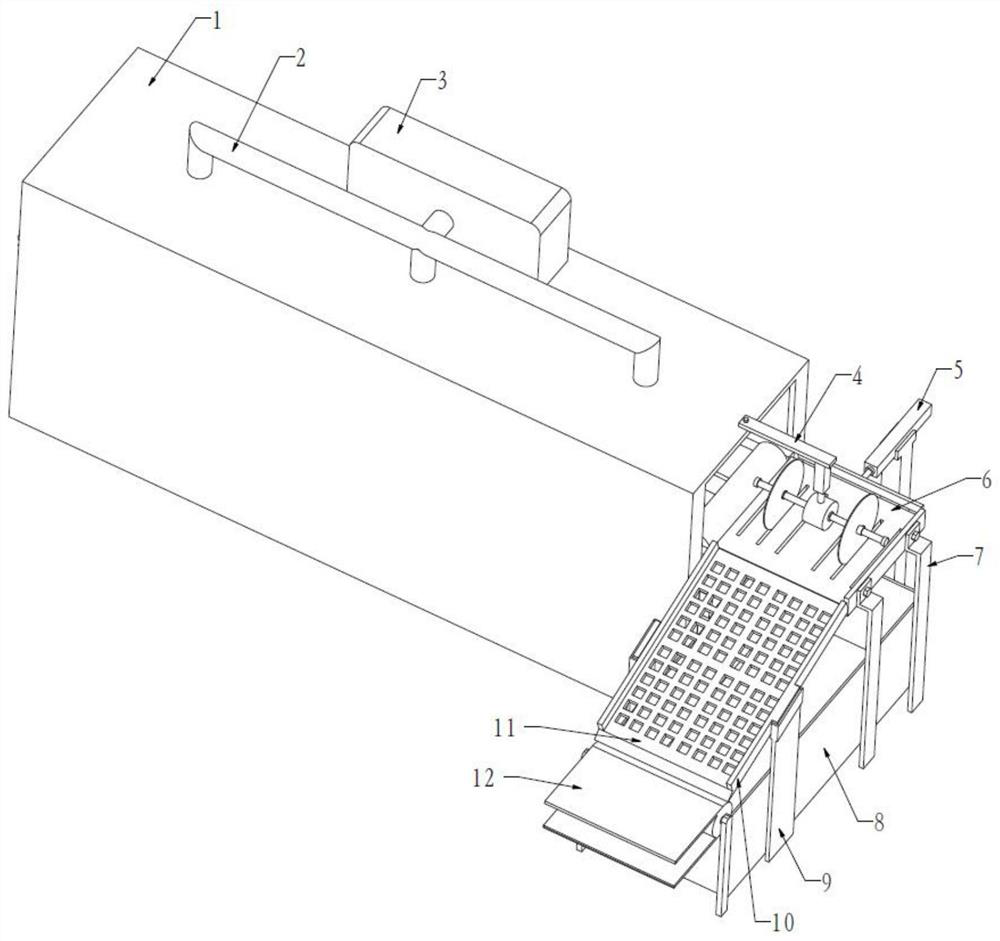

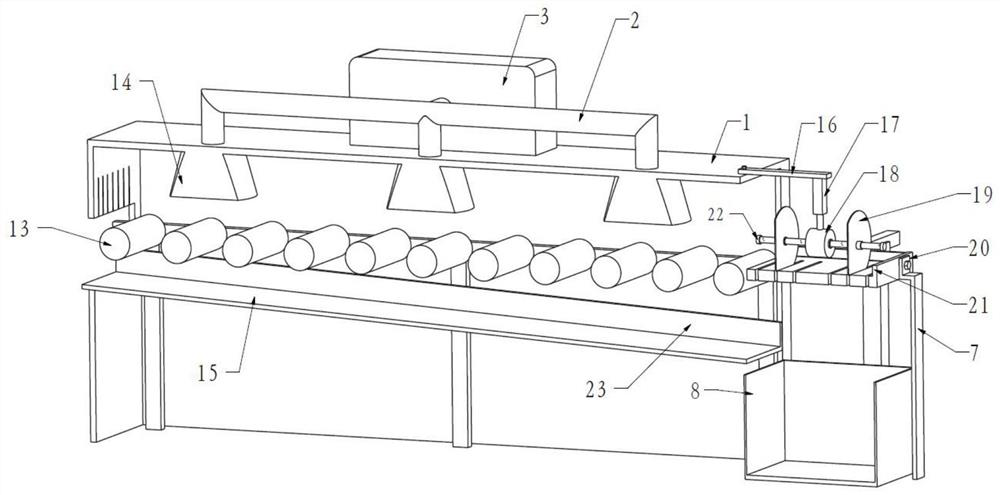

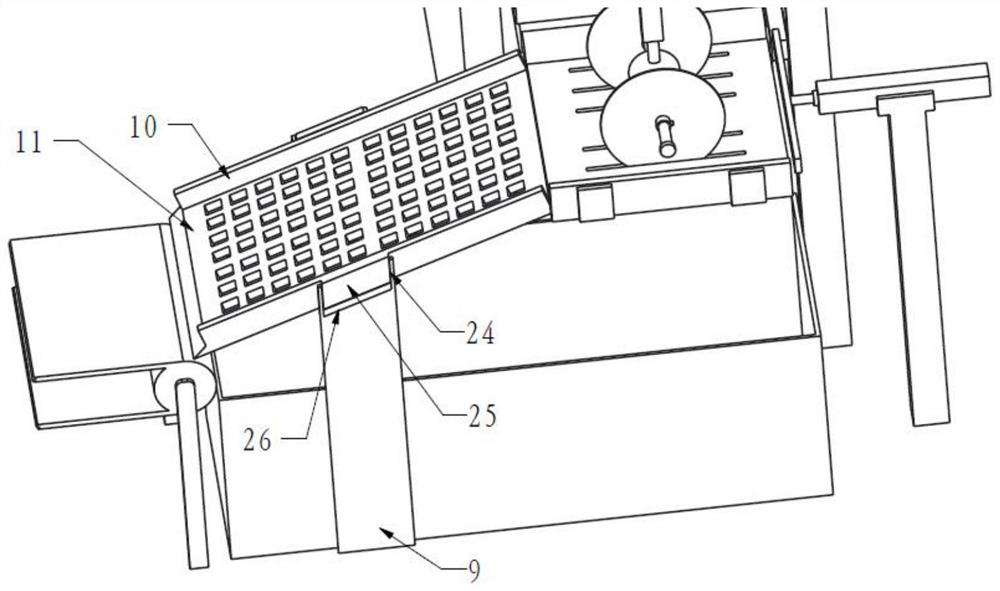

[0029] A device for cooling and cutting hot strip embryo bodies, including a cooling device and a cutting device. The cooling device includes a cooling cover 1. Windows are provided on both sides of the cooling cover 1 for feeding rollers 13 to pass through the cooling cover 1. Inside the cooling cover 1 A cold air nozzle 14 is provided, the feed roller 13 is arranged in the cooling cover 1 and an oil passing plate 15 is arranged below the feed roller 13, and the feed roller 13 is connected with a cutting device; the cutting device includes a cutting assembly 4, and The segment assembly 4 includes a liftable double-head motor 18, the two ends of the double-head motor 18 are connected with a rotating shaft 31, a slidable cutter 19 is arranged on the rotating shaft 31, and a support block 6 is arranged below the double-head motor 18, and the support block 6 accept the spicy strip embryo body conveye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com