Sealing device for central mechanism of tire vulcanizing machine

A technology of sealing device and central mechanism, which is applied in the direction of engine sealing, tires, mechanical equipment, etc., can solve the problems of large lifting resistance of the central rod, large gap between the cylinder head and the ring seat, and internal pressure steam cannot be ejected, etc., to ensure that Overall performance, the effect of overcoming gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

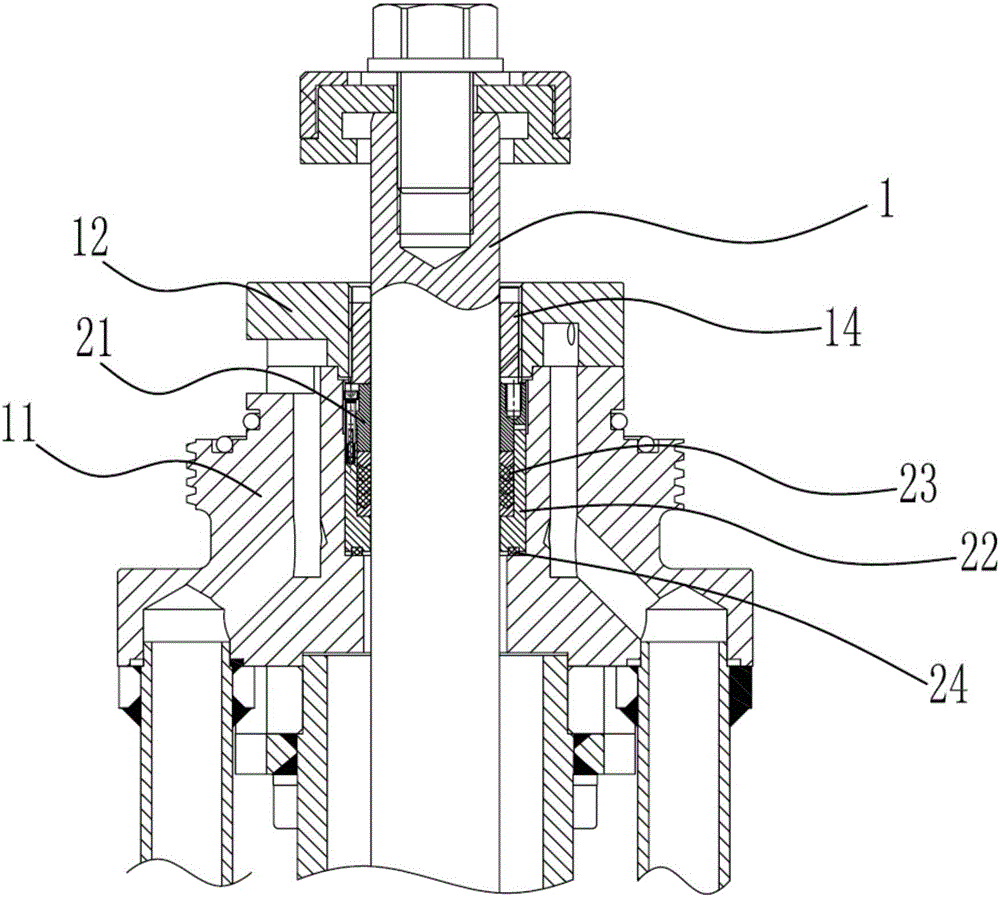

[0026] In order to achieve the purpose of the present invention, as figure 1 As shown, in some embodiments of the sealing device for the center mechanism of a tire vulcanizer according to the present invention, it includes a ring seat 11, a central rod 1 fitted in the ring seat 11, and a cylinder head 12 on the top of the ring seat 11. The rod 1 is provided with a threaded sleeve 14 , the inner ring of the cylinder head 12 is provided with threads corresponding to the threaded sleeve 14 , and the threaded sleeve 14 is screwed on the cylinder head 12 . In this embodiment, by adopting the above-mentioned technical scheme, by setting the threaded sleeve on the central rod, and at the same time, the inner ring of the cylinder head is provided with threads corresponding to the threaded sleeve, so that the compression amount of the sealing ring bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com