Inclined sealing surface valve seat of butterfly valve

A sealing surface and valve seat technology, which is applied in the direction of lift valves, valve devices, engine components, etc., can solve the problems of valve sealing performance degradation, short service life, easy wear, etc., to achieve increased service life, light torque and short time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

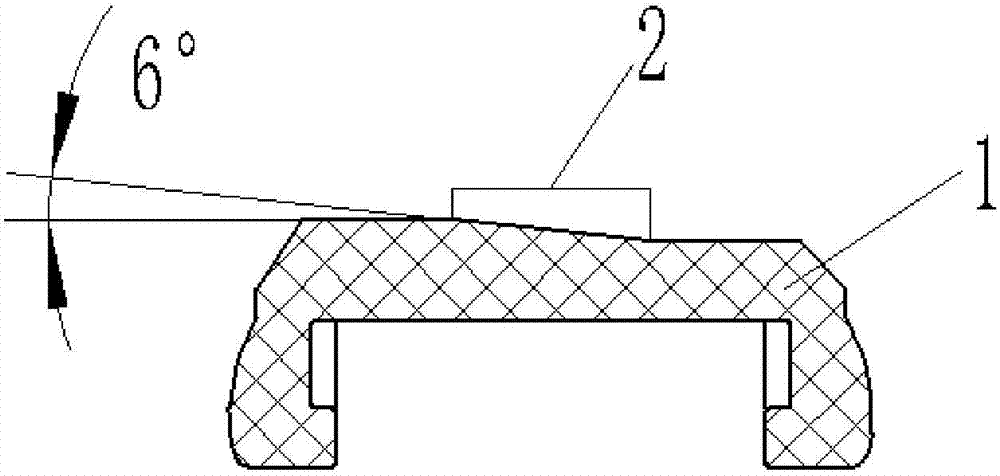

[0008] like figure 1 As shown, a valve seat with an oblique sealing surface of a butterfly valve. During the injection molding process of the valve seat 1, the sealing surface 2 of the valve seat is injection molded to be inclined, and the inclination angle is 6°. This design reduces the pressure between the butterfly plate and the valve seat. The contact time of the sealing surface 2 reduces friction, and the torque will also become lighter. The thickness of the sealing surface 2 of the valve seat is increased by 1-2mm, and the compression amount of the valve seat by the butterfly plate can be adjusted, thereby increasing the service life of the valve seat.

[0009] Finally, it is noted that the above examples are only used to illustrate the technical solutions of the present invention without limitation. Although the present invention has been described in detail with reference to preferred embodiments, those of ordinary skill in the art should understand that the technical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com