Force feedback flexible floating grinding power head and use method thereof

A technology of power head and force feedback, which is applied in the direction of grinding machine parts, grinding/polishing equipment, workpiece feed movement control, etc., can solve problems such as increased labor costs, poor grinding accuracy, etc., and achieve a solution The cost is generally too high, the effect of convenient maintenance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

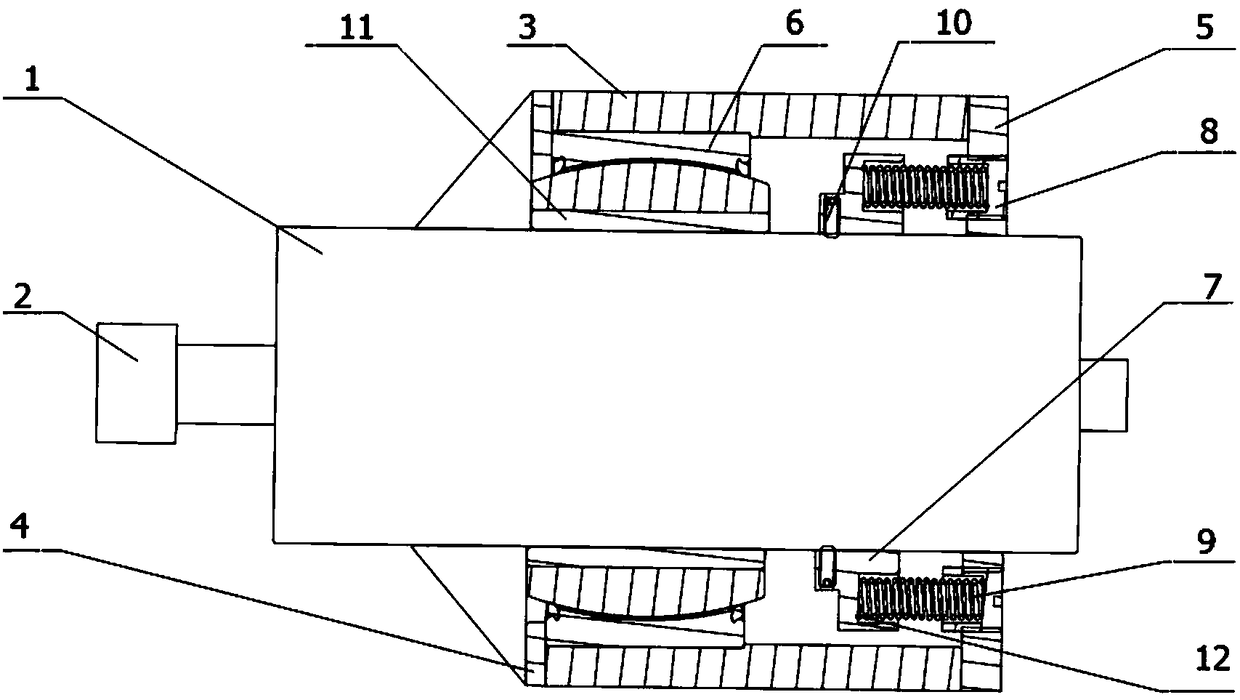

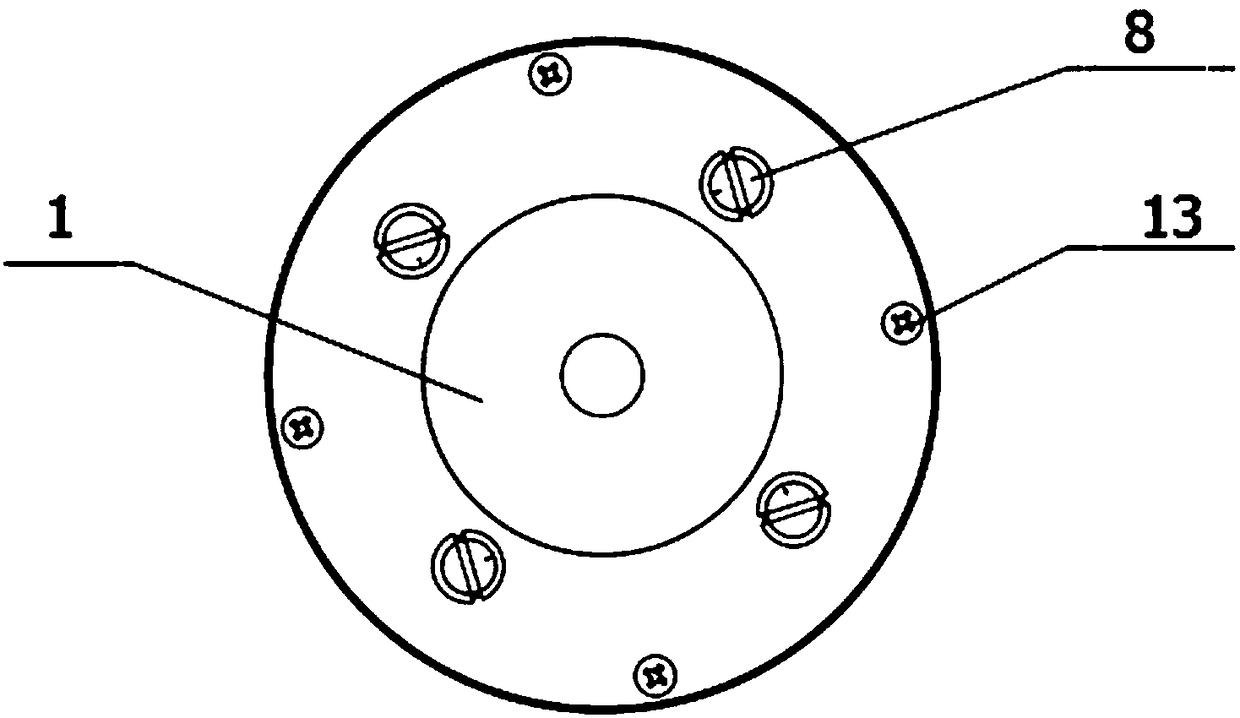

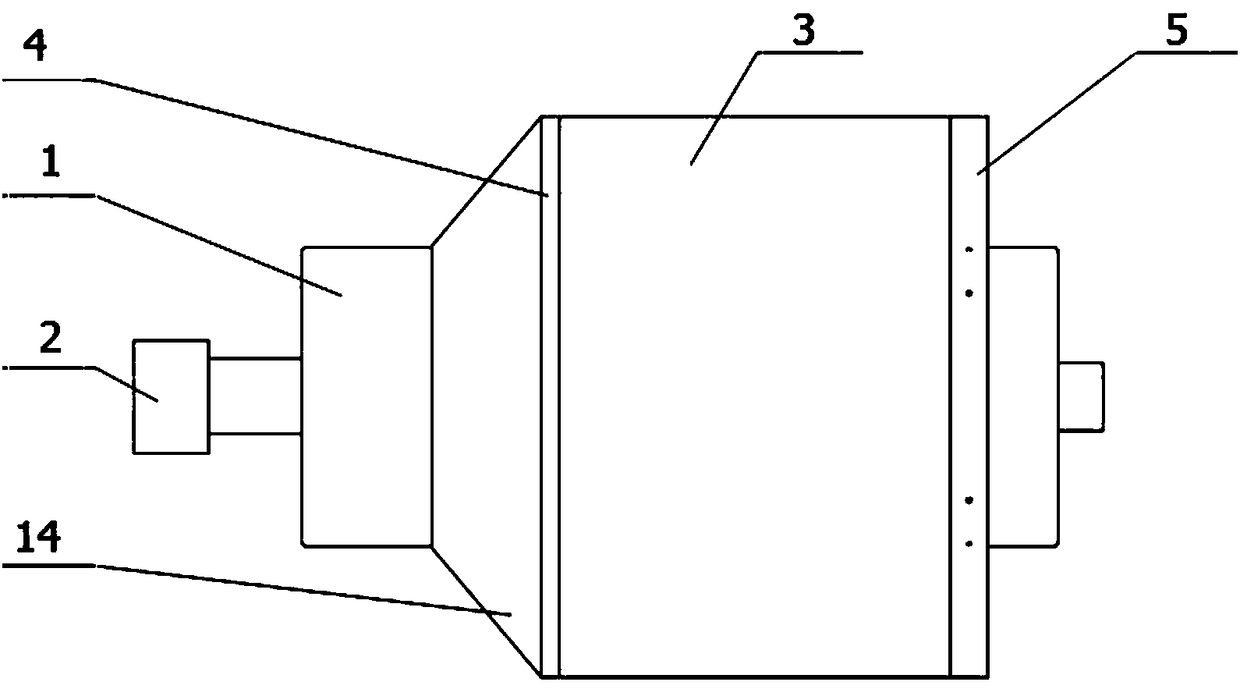

[0031] Such as Figure 1 to Figure 5 As shown, a force feedback flexible floating grinding power head includes a main housing 3, the main housing 3 has a built-in spindle 1 for realizing contact, and the end of the main housing 3 is provided with a fixing mechanism, A positioning mechanism is provided between the main housing 3 and the main shaft 1 , and a flexible detection mechanism for sensing grinding force is also provided between the main housing 3 and the main shaft 1 .

[0032] The fixing mechanism is arranged at the end of the main housing 3 for fixing the main shaft 1; the positioning mechanism is arranged between the main housing 3 and the main shaft 1 for determining the relative position between the main housing 3 and the main shaft 1. Position; the flexible detection mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com