Extruded sealing structure of charging port, shell and light fitting

A technology of extrusion sealing and charging port, which is applied in the parts of lighting devices, lighting devices, lighting and heating equipment, etc., can solve the problems of complicated and time-consuming glue filling process, hinder work efficiency, occupy working hours, etc., and achieve sealing effect. Adjustable, improve work efficiency, adjustable sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

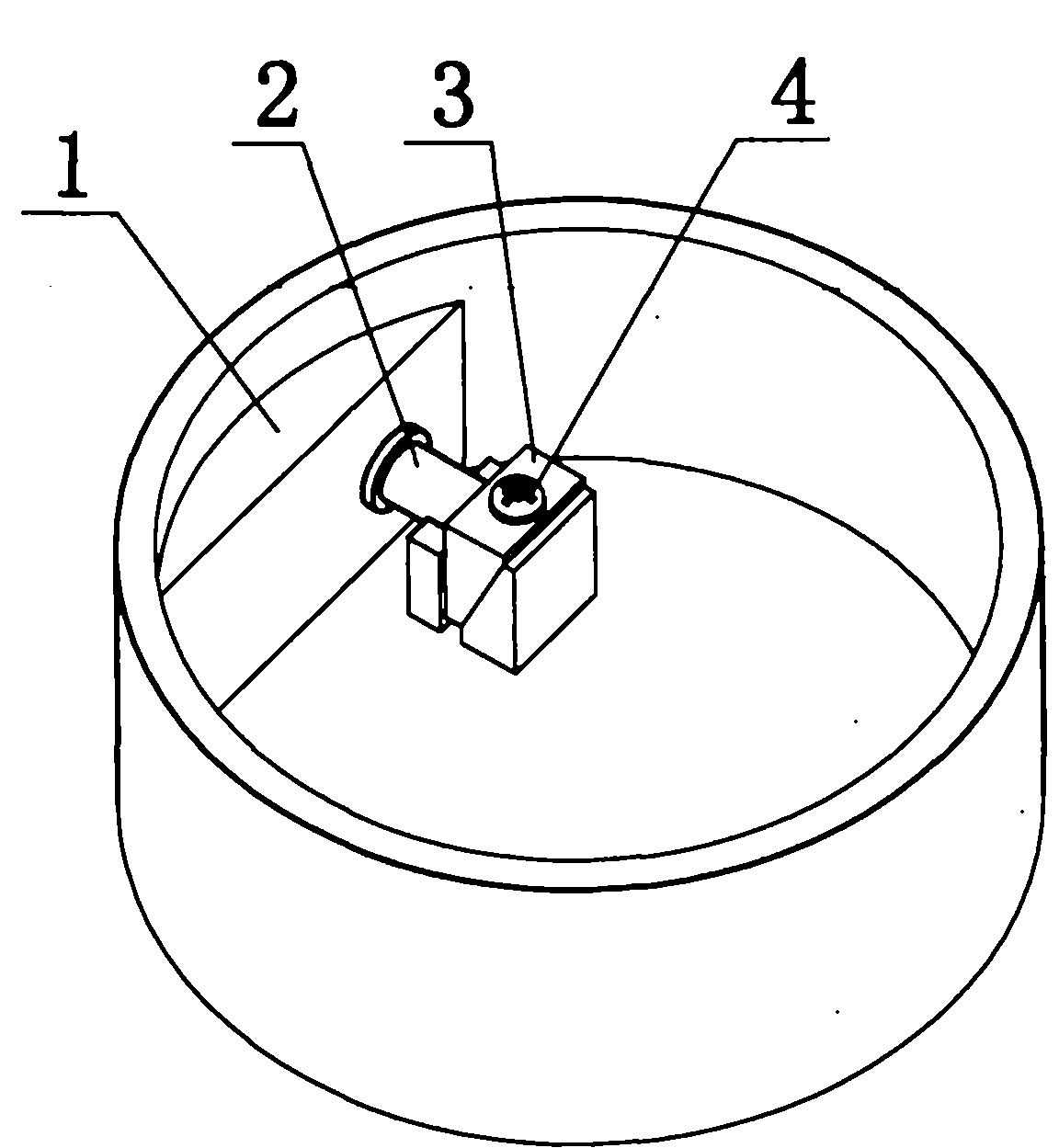

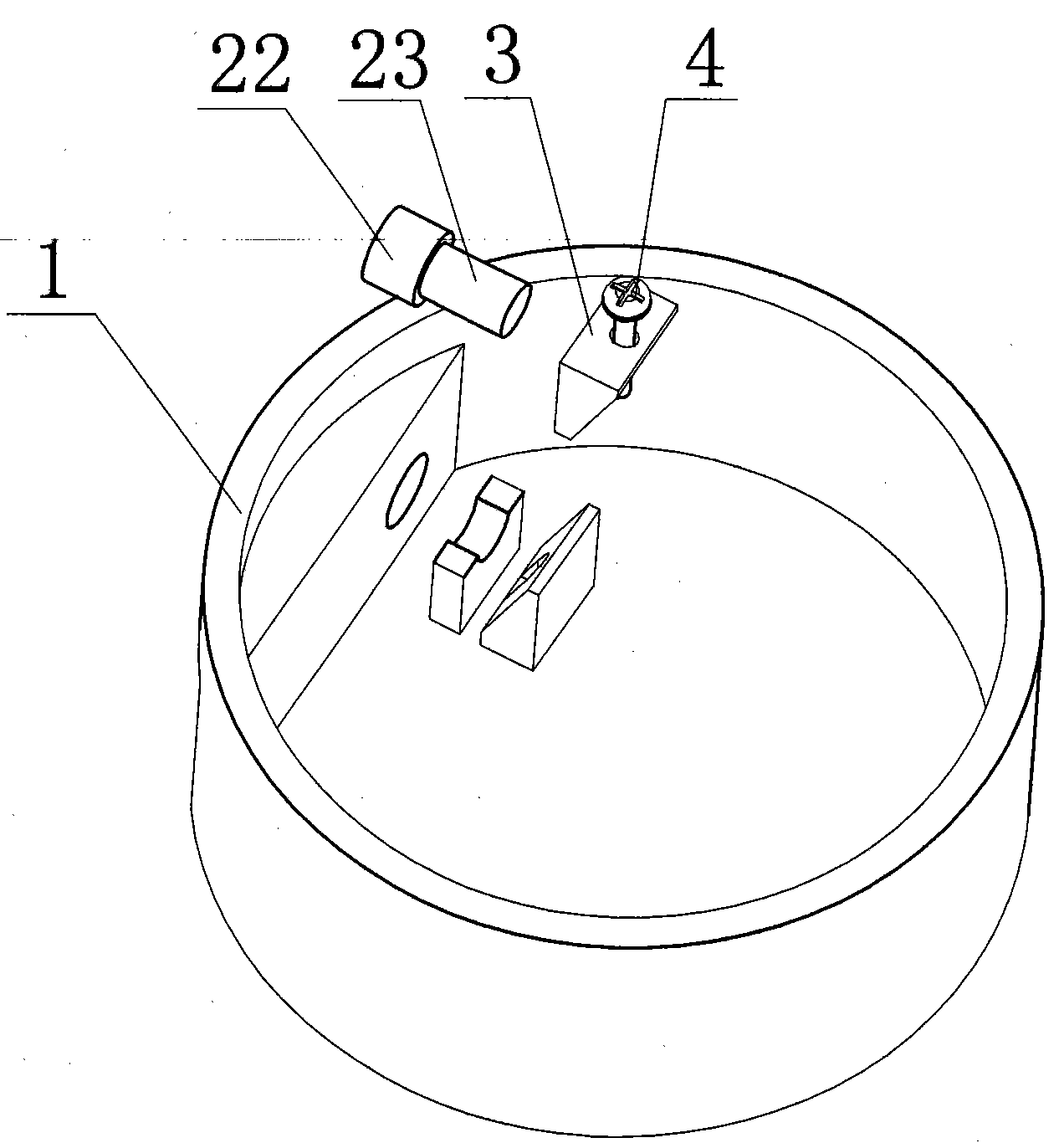

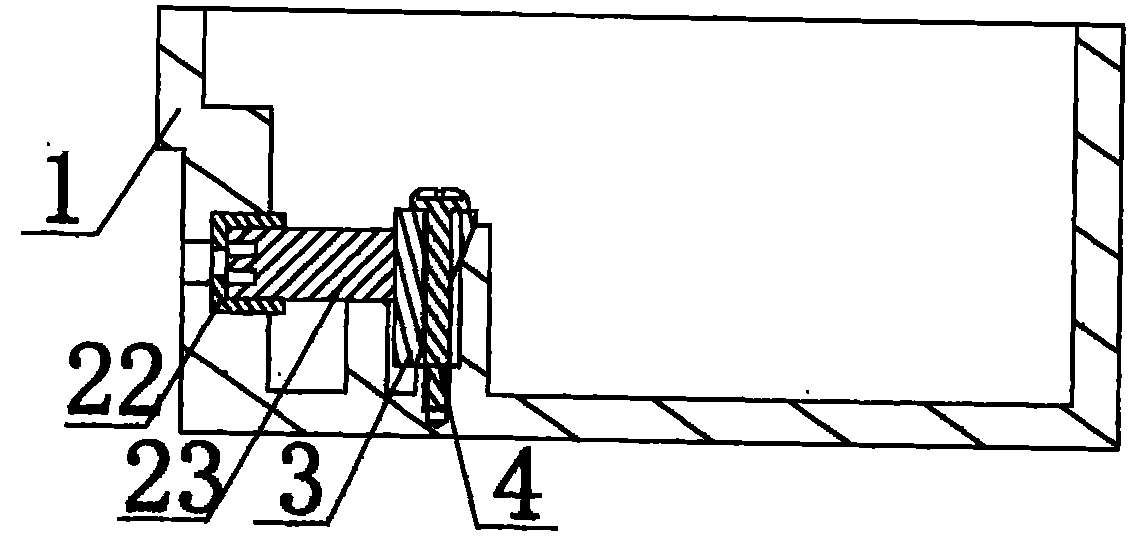

[0023] An embodiment of the present invention is a wedge-shaped extrusion sealing structure of a charging port, which is applied to the external charging port and the housing, the charging port includes a sealing ring and a charging socket, and the wedge-shaped extrusion sealing structure Including a wedge-shaped block, which is movably installed on the wedge-shaped seat of the housing, such as figure 1 with figure 2 As shown, one side of the wedge-shaped block is in matching contact with the wedge-shaped seat, that is, the two slopes meet; the other side of the wedge-shaped block is in rigid and movable contact with the charging female seat, for example, it is in contact with the above-mentioned slope Similarly, the connecting surfaces of the two can be inclined surfaces, and for another example, one of the connecting surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com