Automatic separator for needles of infusion apparatus

A technology of automatic separation and infusion set, which is applied in the direction of waste collection and transfer, garbage collection, household appliances, etc., and can solve problems such as needle stick injuries, medical staff's physical and mental damage, occupational safety, and heavy workload in wards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

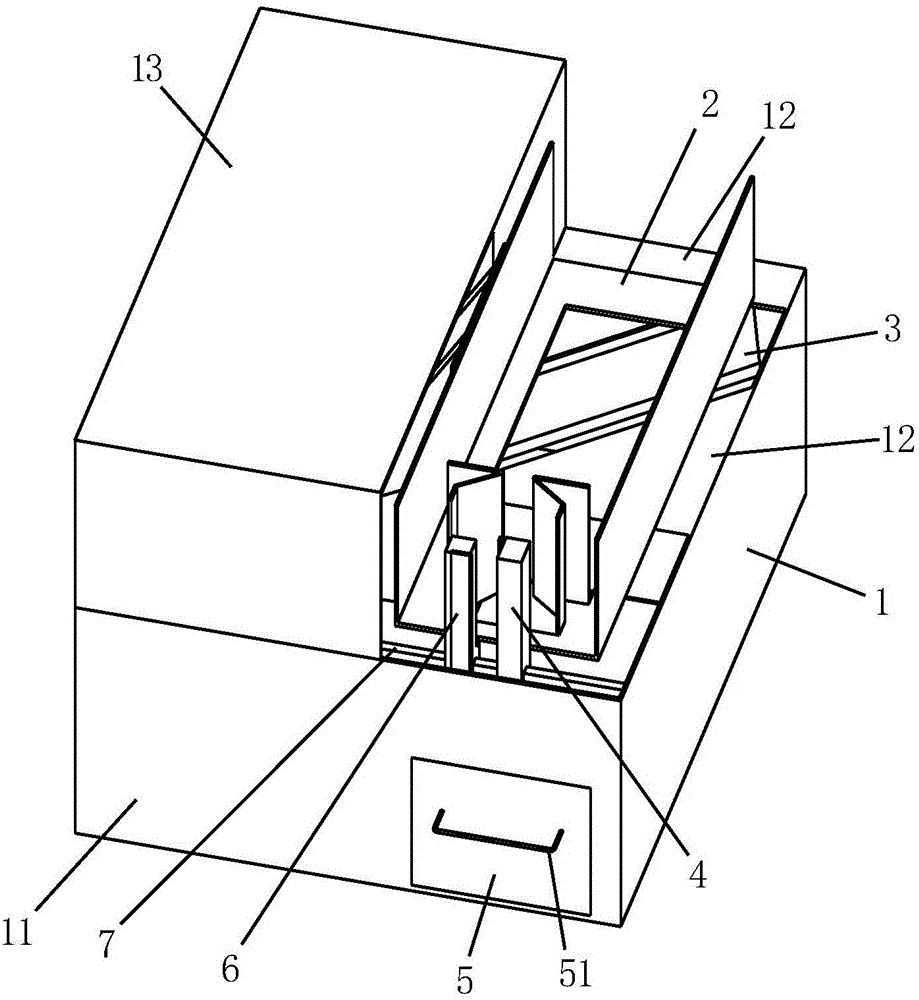

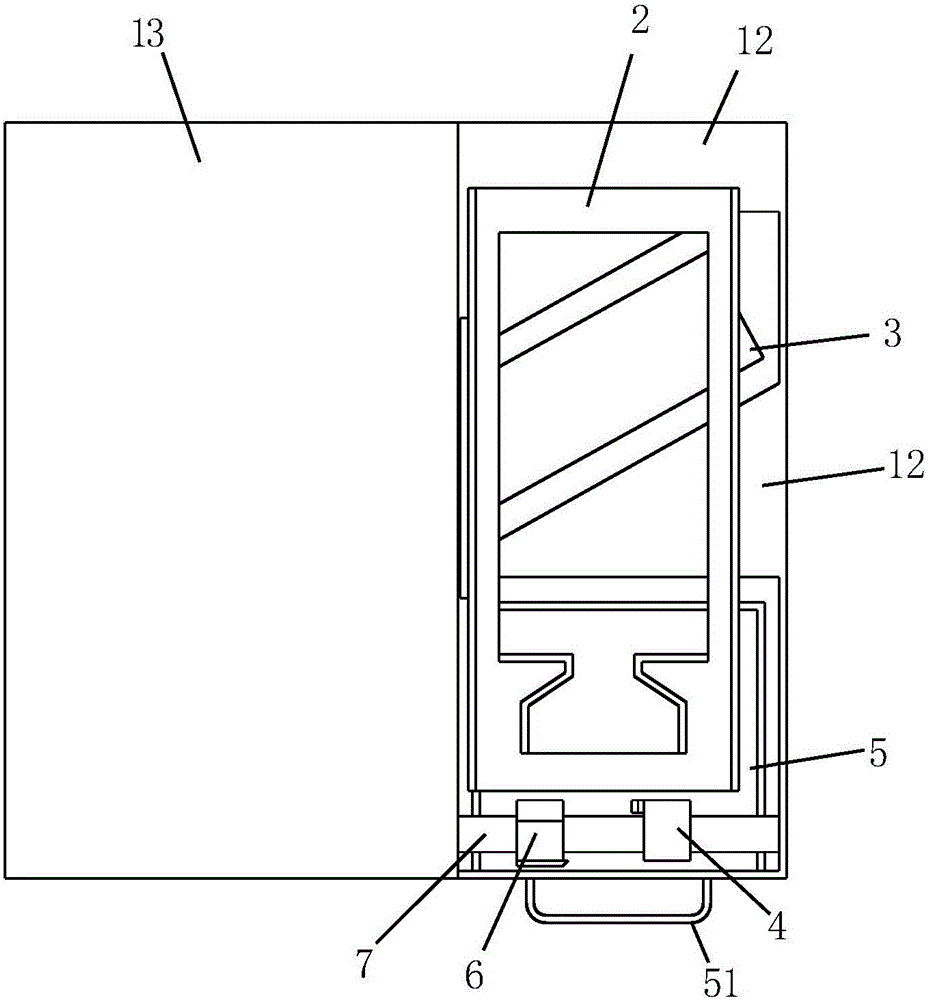

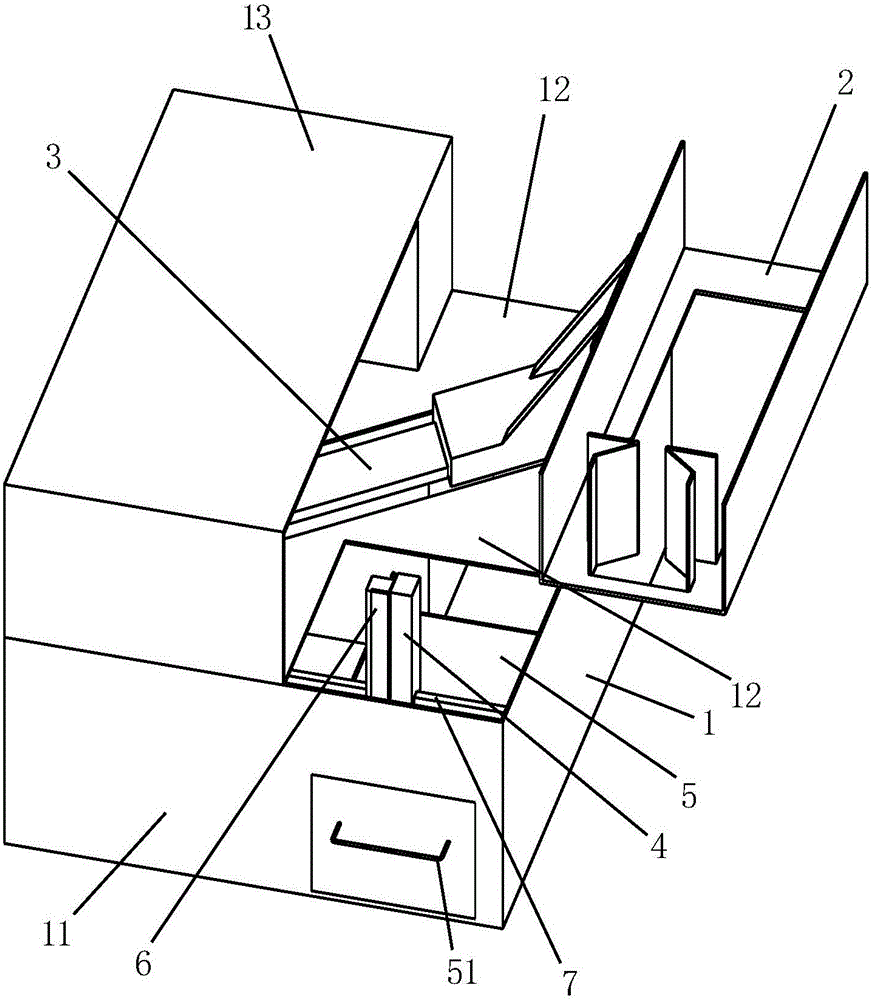

[0020] Such as figure 1 , figure 2 and image 3 As shown, this automatic needle separation machine for infusion sets includes a square housing 1, an infusion bag placement plate 2, a main slide rail 3, a blade assembly 6, a blade stopper 4, a sharps collection box 5 and an auxiliary slide rail 7, the main Both the slide rail and the auxiliary slide rail are arranged in the casing, and the transfusion bag placement plate, the blade assembly and the blade stopper are located above the casing. The main slide rail 3 and the auxiliary slide rail 7 are all parallel to the bottom surface of the housing 1, such as Figure 4 As shown, the auxiliary slide rail 7 is located at the rear side of the front side 11 of the housing and is parallel to the front side 11. The main slide rail 3 is obliquely placed in the housing, and the left end 31 of the main slide rail is located at the front of the housing. The right end 32 of the rail is located at the rear of the housing. Such as Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com