Steel strand lifting device and lifting method

A lifting device and steel strand technology, which is applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of being unable to meet the low cost requirements of marginal oil fields, increasing comprehensive leasing costs, and high manufacturing costs of lifting devices. Significant comprehensive cost advantages, saving installation time at sea, and low manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

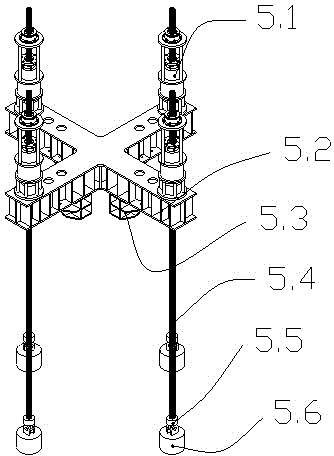

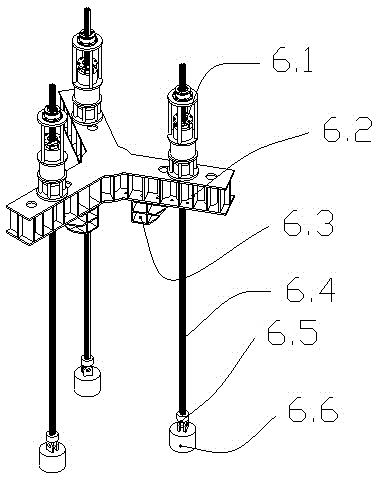

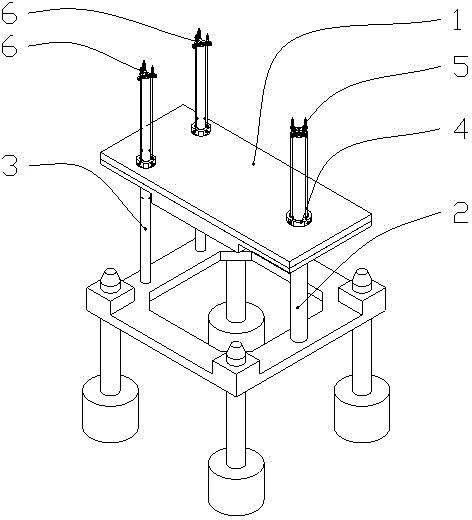

[0026] Such as figure 1 As shown, the main pile leg steel strand lifting device 5 includes 4 steel strand lifting devices 5.1, four-leg hoisting supports 5.2, sliding limit blocks 5.3, steel strands 5.4, lifting heads 5.5, connecting bases 5.6, four Leg hoisting support 5.2 is assembled and welded by plates, and has a strong load-bearing beam structure with an I-shaped cross section, such as Figure 3-4 As shown, the four-leg lifting support 5.2 is located at the top of the main pile leg 2, the center of the four-leg lifting support 5.2 is aligned with the center of the main pile leg 2, and the steel strand lifting device 5.1 is located at the strong bearing capacity of the four-leg lifting support 5.2 On the upper part of the beam, the steel strand lifting device 5.1 is connected to the four-leg hoisting support 5.2 through flanges, and the I-beam of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com