Valve management optimization method based on steam distribution mode switchover for 200MW heat supply unit

A steam distribution method and heating unit technology, applied in mechanical equipment, engine components, engine control, etc., can solve the problems of not considering the optimal valve position, the efficiency of the high-pressure cylinder of the steam turbine cannot be optimized, etc., and achieve the improvement of the efficiency of the high-pressure cylinder , Improving the efficiency of high pressure cylinders and overcoming the effect of insufficient data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

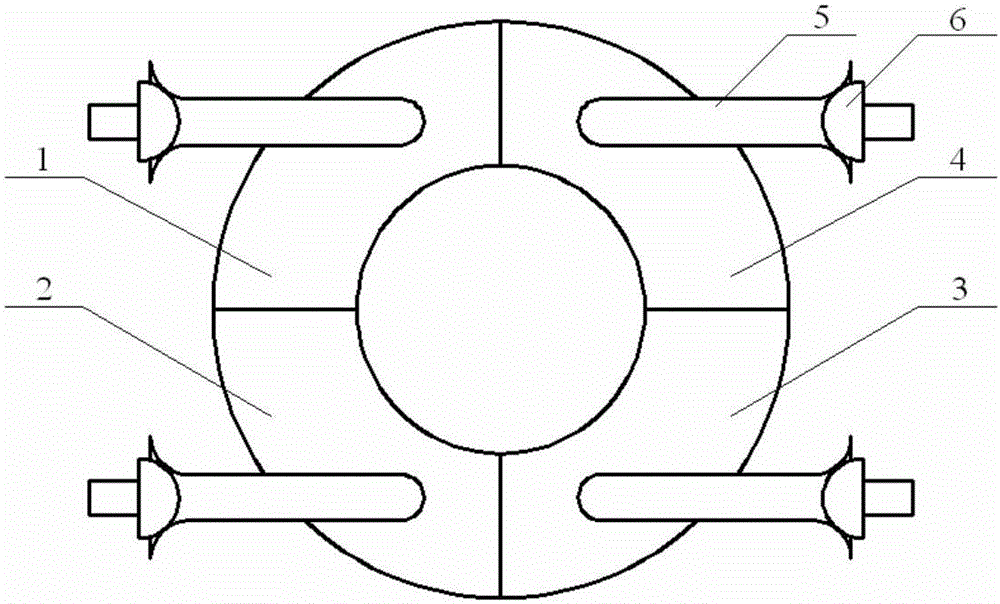

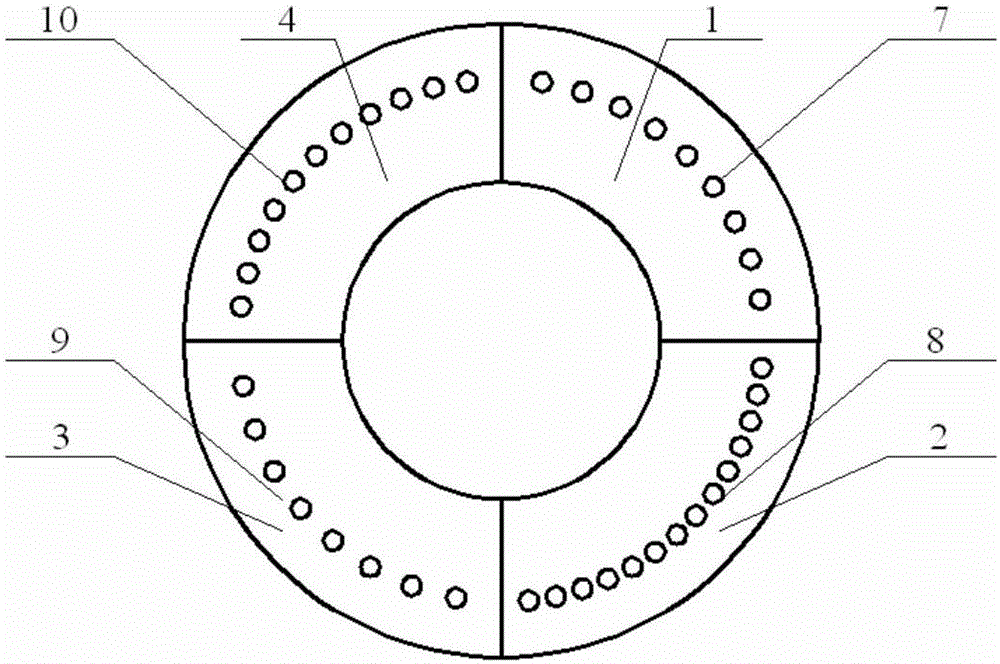

[0032] Specific implementation mode one: combine Figure 1 to Figure 4 To illustrate this embodiment, the valve management optimization method for a 200MW heating unit based on the switching of the steam distribution mode described in this embodiment is realized through the following steps:

[0033] Step 1. According to the actual situation of the power plant equipment, set two steam distribution methods: the set steam distribution method is diagonal steam distribution, and the setting principle is: the first valve group is two diagonal valves, and the second valve group is another The lower cylinder valve, the third valve group is another upper cylinder valve;

[0034] Step 2. Carry out load-up and down-load experiments on the heating unit, obtain relevant experimental data, and calculate the efficiency of the high-pressure cylinder of the unit under different steam distribution methods:

[0035] The high pressure cylinder efficiency is defined as where the main steam enth...

specific Embodiment approach 2

[0047] Specific implementation mode two: combination Figure 1 to Figure 4 To illustrate this embodiment, the two steam distribution methods in Step 1 of the valve management optimization method for a 200MW heating unit based on the switching of steam distribution methods described in this embodiment are:

[0048] The first steam distribution method: the first valve group is No. 1 valve 1 and No. 3 valve 3, the second valve group is No. 2 valve 2, and the third valve group is No. 4 valve 4;

[0049] The second steam distribution method: the first valve group is No. 2 valve 2 and No. 4 valve 4, the second valve group is No. 1 valve 1, and the third valve group is No. 3 valve 3.

[0050] The efficiency curve of the high-pressure cylinder is calculated by using the temperature and pressure of the main steam and the exhaust temperature and pressure data of the high-pressure cylinder collected in the load-up and down-load tests under the above two steam distribution methods.

[00...

Embodiment

[0057] Combining with the transformation example of a 200MW heating unit and Figure 4 to Figure 10 The steam distribution mode switching method is described. The two steam distribution modes in Step 1 of the steam distribution mode switching based valve management optimization method for 200MW heating units described in the implementation mode are:

[0058] The first steam distribution method: the first valve group is No. 1 valve 1 and No. 3 valve 3, the second valve group is No. 2 valve 2, and the third valve group is No. 4 valve 4;

[0059] The second steam distribution method: the first valve group is No. 2 valve 2 and No. 4 valve 4, the second valve group is No. 1 valve 1, and the third valve group is No. 3 valve 3.

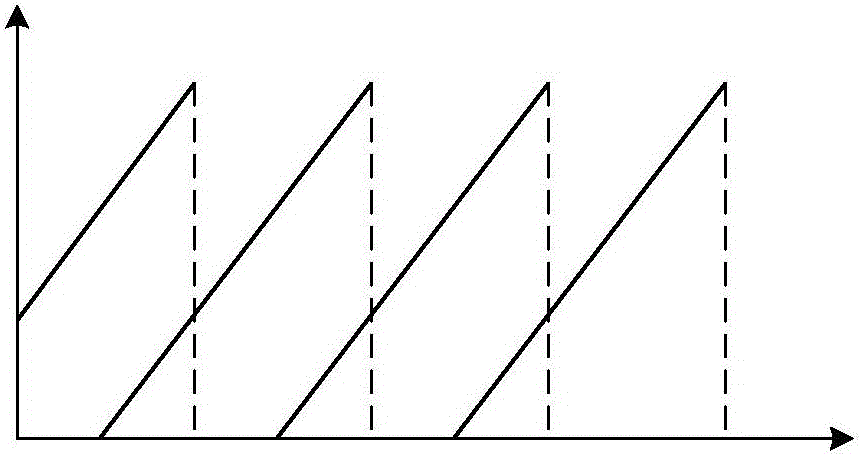

[0060] Use the above two steam distribution methods to do load lifting and lowering tests. The specific experimental process is as follows: Figure 5a and Figure 5b As shown, the valve opening sequence diagrams of the two steam distribution methods are as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com