Explosive environment simulation device for protected vehicle bottom

An environment simulation device and vehicle technology, which is applied in the direction of measuring device, vehicle test, machine/structural component test, etc., can solve the problems of obtaining high-precision experimental data and not being able to guarantee the safety of the explosive environment, so as to achieve accurate experimental data, It is convenient to obtain high-precision experimental data and the effect of convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

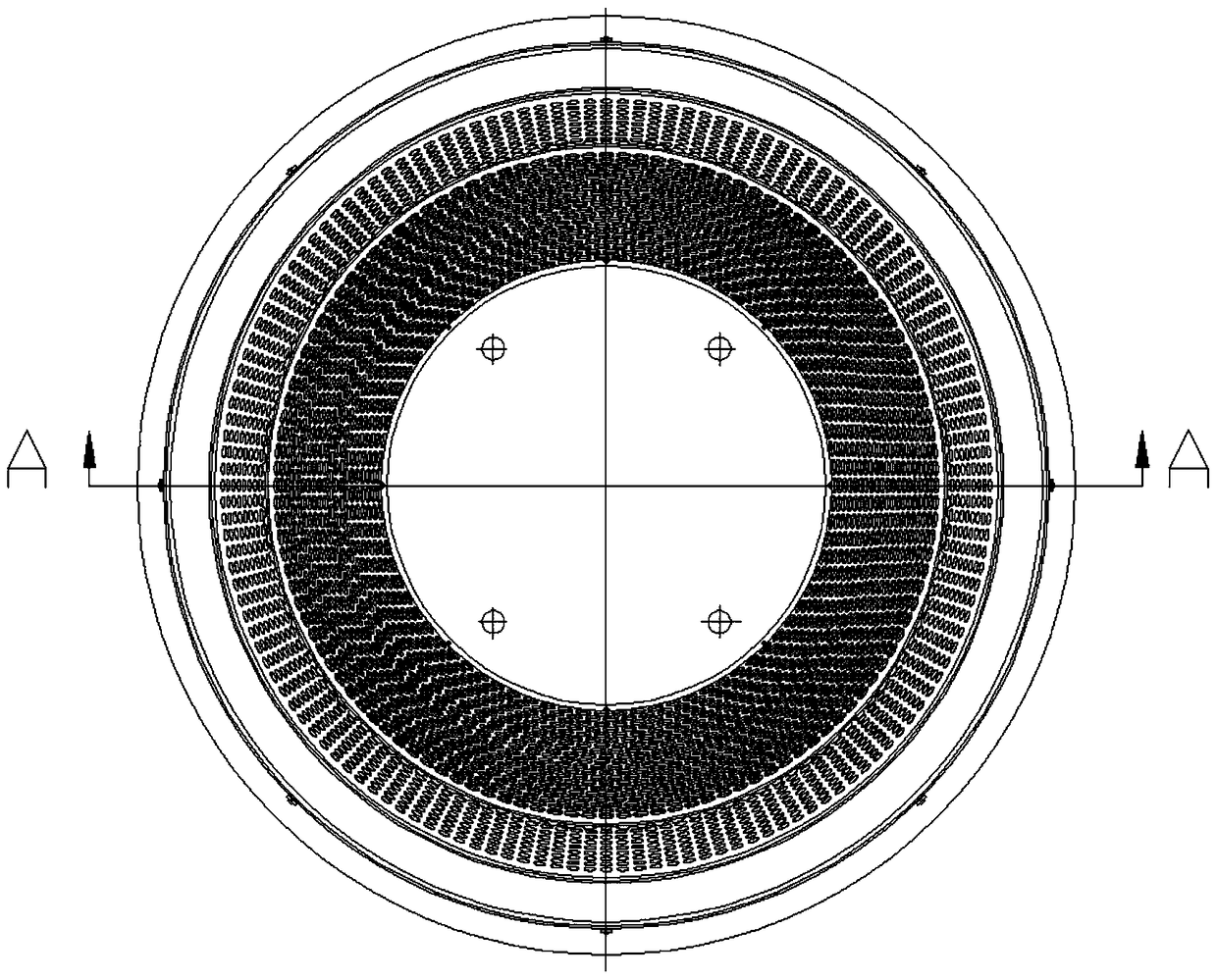

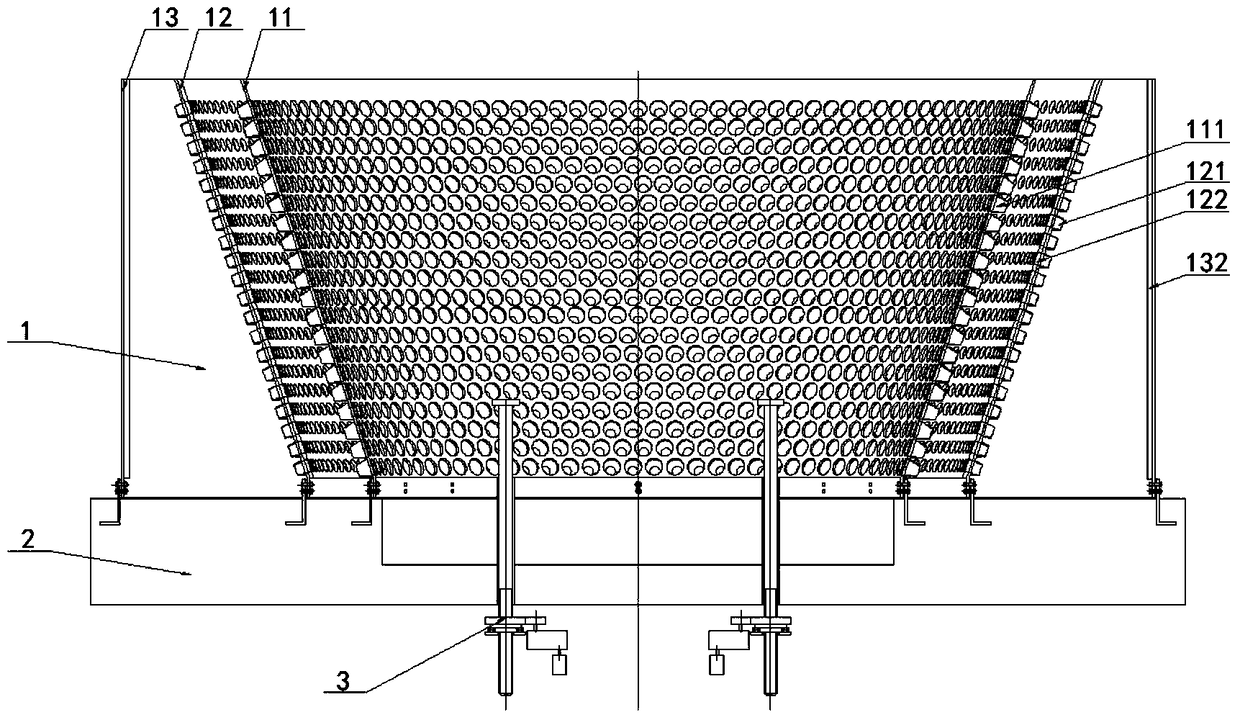

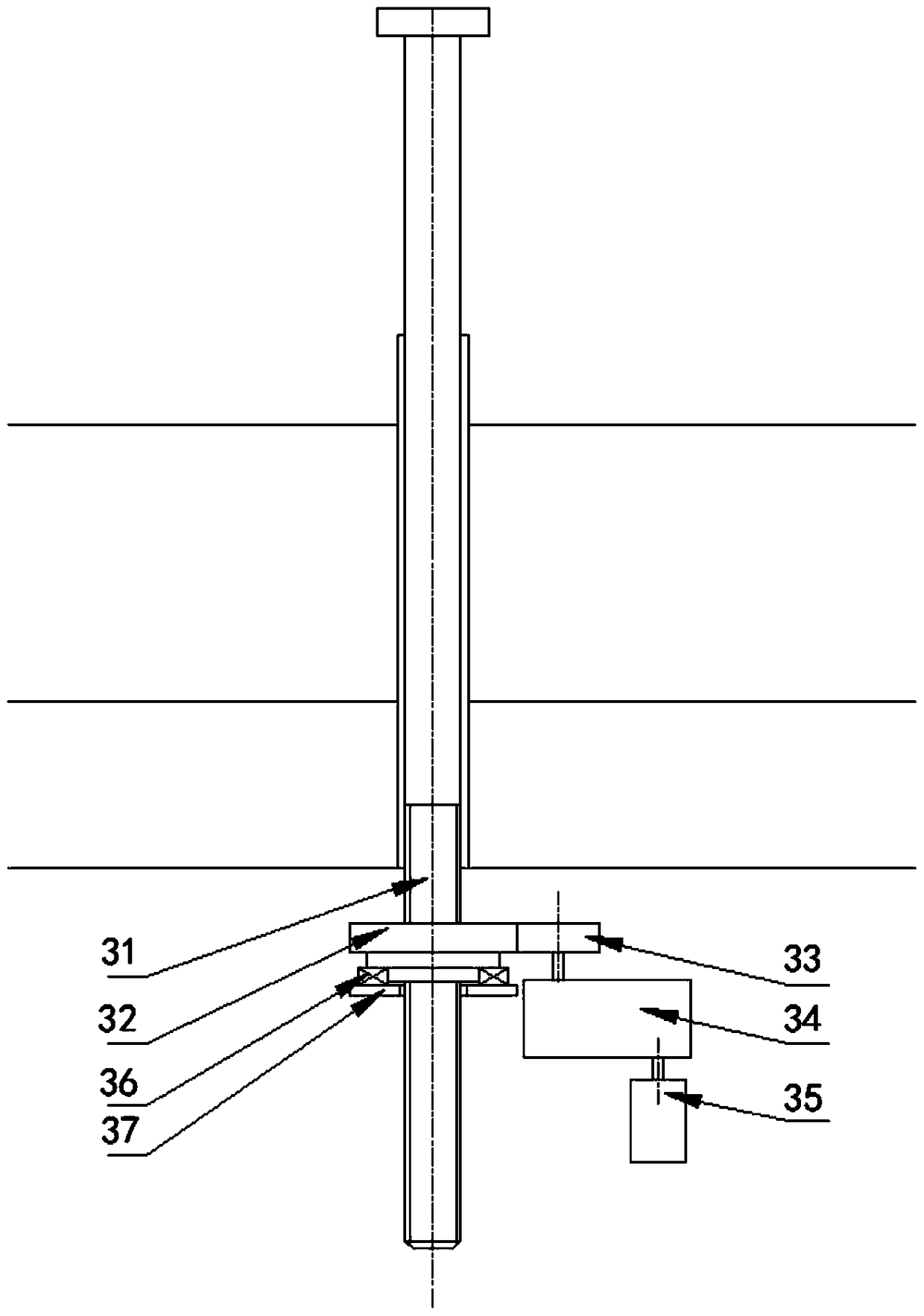

[0016] Such as figure 1 , 2 As shown, the explosive environment simulation device at the bottom of the protected vehicle of the present invention includes a protective wall 1, a fixed platform 2 fixedly connected to the lower part of the protective wall 1, and a support adjustment mechanism 3 placed at the lower part of the fixed platform 2. The protective wall 1 includes a The inner wall 11, the middle wall 12 and the outer wall 13 arranged concentrically from the inside to the outside, the inner wall 11 and the middle wall 12 are conical tubes with a large upper part and a smaller lower part, and the outer wall 13 is a cylindrical tube, A plurality of closely arranged horn holes 111, 121 are arranged on the inner wall 11 and the middle wall 12. Each of the horn holes 111, 121 is large inside and small outside, and its central axis points to the explosion center. The middle wall 12 is pasted with aluminum foam 122 inside, and the inside of the outer wall 13 is pasted with fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com