A light-emitting diode chip and its manufacturing method

A technology for light-emitting diodes and a manufacturing method, which is applied to electrical components, circuits, semiconductor devices, etc., can solve the problems of low reflectivity of non-vertically incident light, low luminous efficiency of LED chips, etc., to improve stability, improve luminous brightness and luminous The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

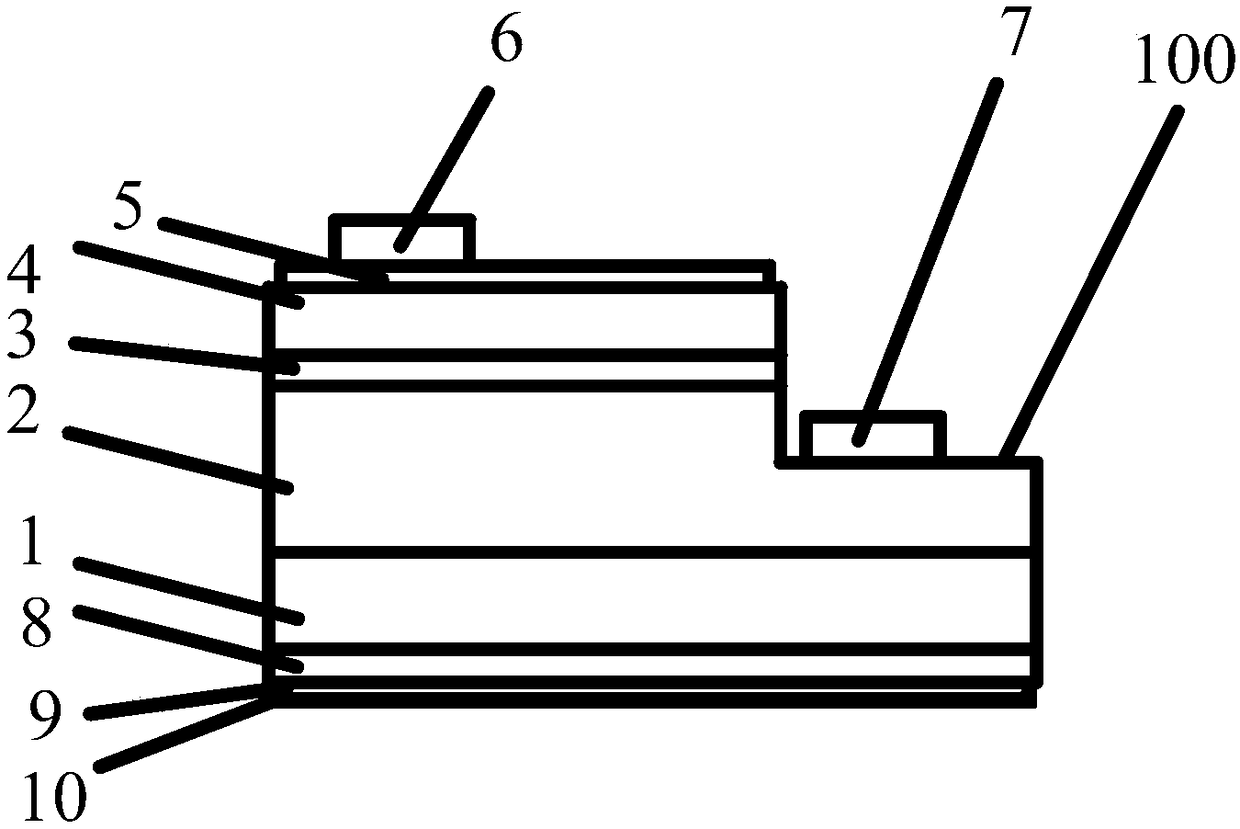

[0036] An embodiment of the present invention provides a light emitting diode chip, see figure 1 , the light-emitting diode chip includes a substrate 1, an N-type layer 2, a light-emitting layer 3, a P-type layer 4, a transparent conductive film (TCO) 5, a P-type electrode 6, an N-type electrode 7, a DBR 8, and an Ag metal reflective layer 9 and metal protective layer 10, N-type layer 2, light-emitting layer 3, and P-type layer 4 are sequentially stacked on the first surface of substrate 1, and P-type layer 4 is provided with a concave hole extending from P-type layer 4 to N-type layer 2. The groove 100, the transparent conductive film 5 and the P-type electrode 6 are sequentially arranged on the P-type layer 4, the N-type electrode 7 is arranged on the N-type layer 2, and the DBR 8, the Ag metal reflective layer 9, and the metal protection layer 10 are sequentially arranged on the substrate. On the second surface of the bottom 1, the metal protective layer 10 and the DBR 8 fo...

Embodiment 2

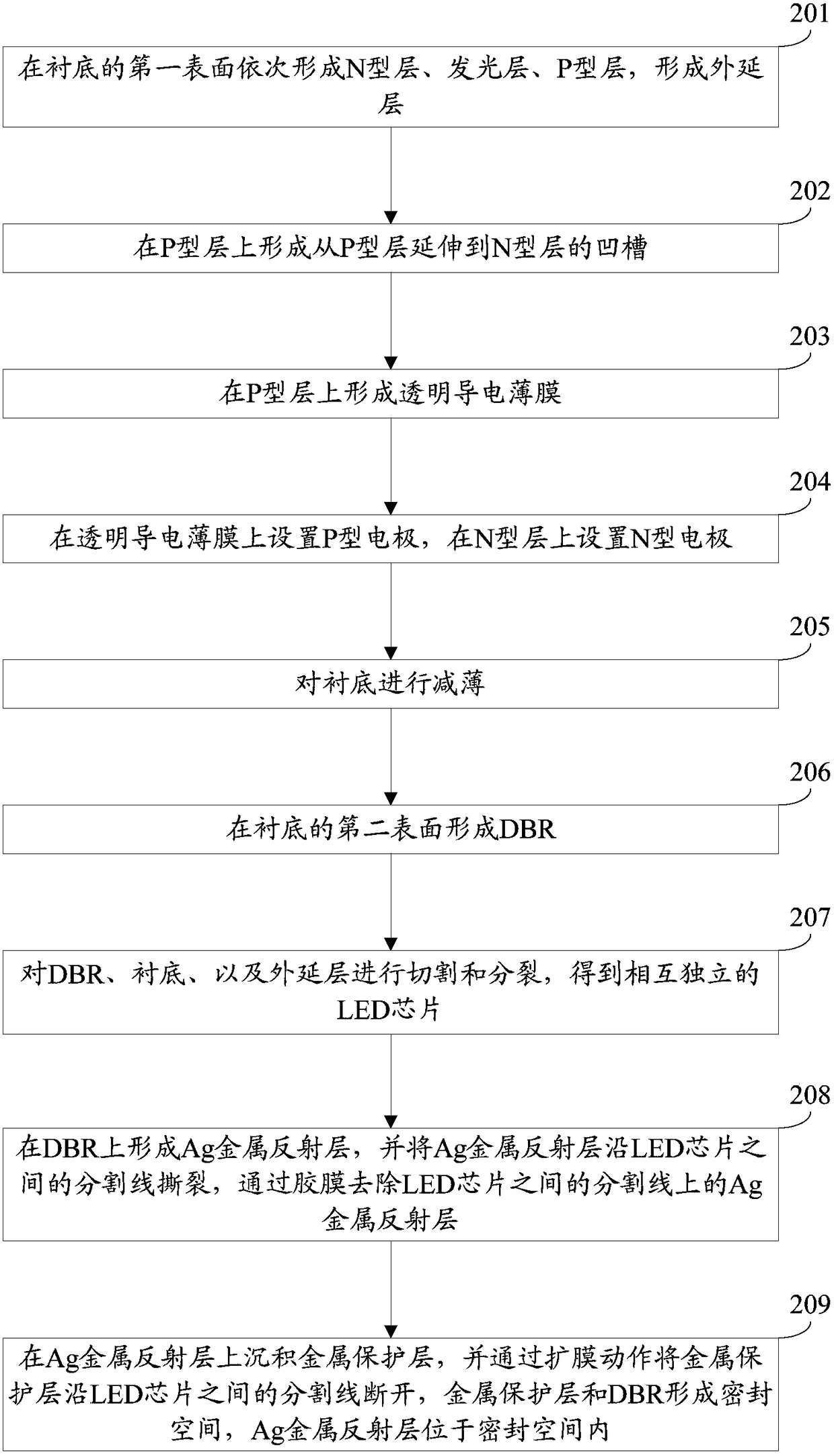

[0048] An embodiment of the present invention provides a method for manufacturing a light emitting diode chip, see figure 2 , the production method includes:

[0049] Step 201: sequentially forming an N-type layer, a light-emitting layer, and a P-type layer on the first surface of the substrate to form an epitaxial layer.

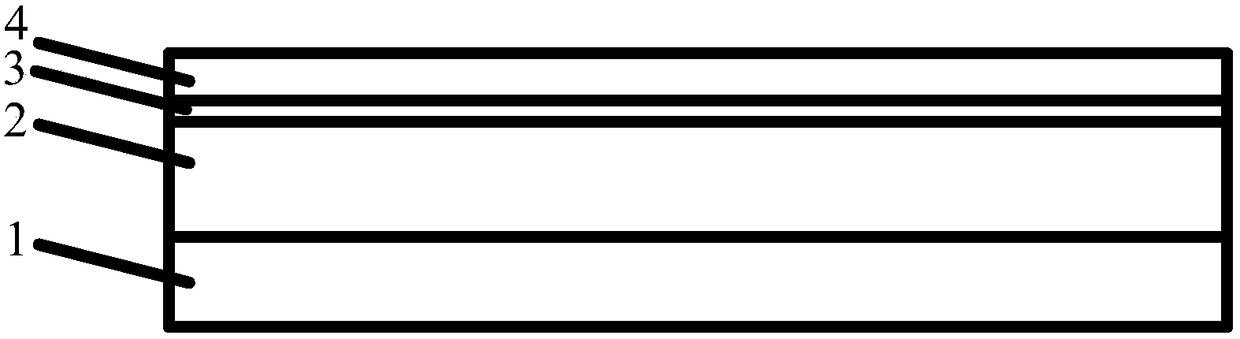

[0050] Figure 3a It is a schematic structural diagram of the LED chip after step 201 is performed. Wherein, 1 is a substrate, 2 is an N-type layer, 3 is a light-emitting layer, and 4 is a P-type layer.

[0051]In this embodiment, the N-type layer may be an N-type GaN layer, the light emitting layer may be alternately stacked InGaN layers and GaN layers, and the P-type layer may be a P-type GaN layer.

[0052] Optionally, the substrate may be one of a flat-surfaced sapphire substrate, a patterned sapphire substrate (Patterned Sapphire Substrate, PSS for short), a Si substrate, a GaN substrate, a SiN substrate, a SiC substrate, and a glass substrate. sp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap