Mold

A mold and punch technology, which is applied in the field of molds to reduce the appearance defect rate of aluminum sheet metal, can solve the problem of high appearance defect rate, and achieve the effect of reducing the appearance defect rate and production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

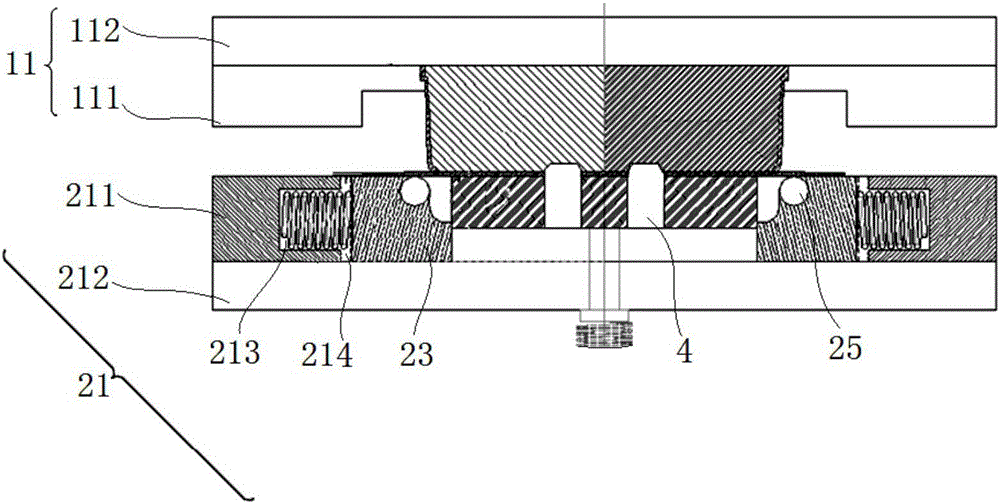

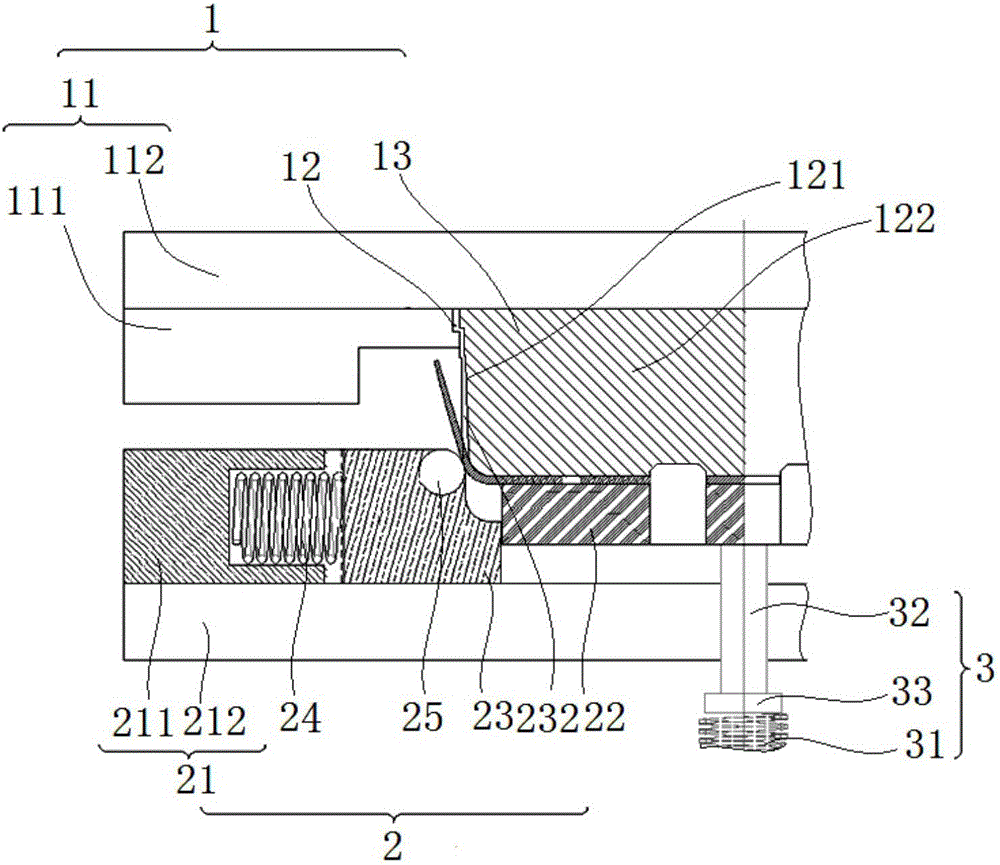

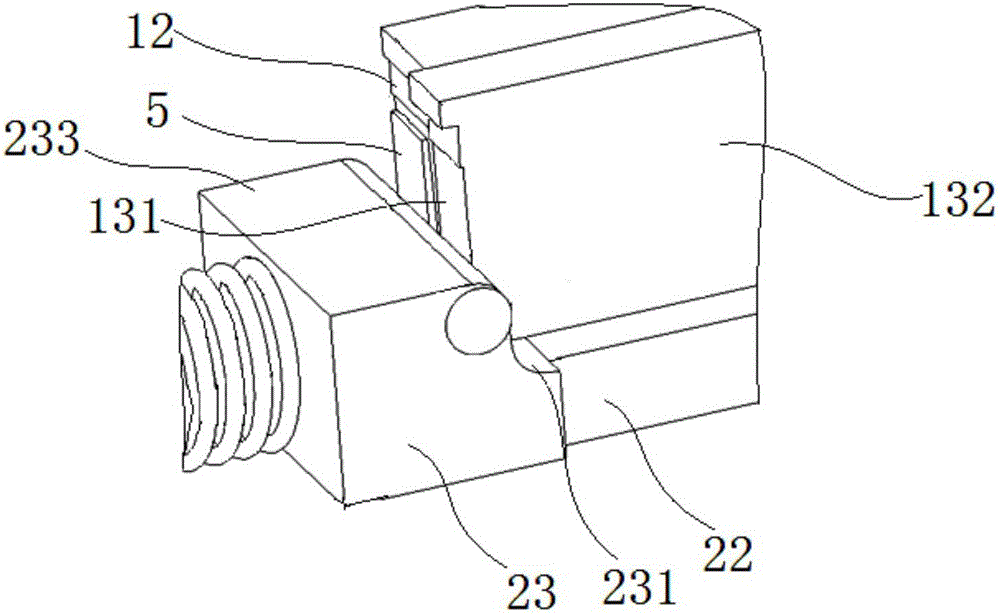

[0029] The application will be further described in detail below through specific embodiments in conjunction with the drawings. In the text, "front", "rear", "left", "right", "up" and "down" are all based on the placement state of the mold in the drawings.

[0030] When the existing mold is bending and forming the aluminum sheet metal 5 of gradual thickness, since the upper mold 1 and the lower mold 2 are in vertical relative motion, the forces of the two against the aluminum sheet metal 5 are relatively concentrated. In the vertical direction, it is unable to provide sufficient force in the bending direction to bend the aluminum sheet metal 5, so the existing mold has a large springback when bending the aluminum sheet metal 5 It cannot be overcome, resulting in that the bent aluminum sheet metal 5 cannot meet the requirements of the bending angle. In order to overcome the rebound and adjust the bending angle in place, the existing forming process will adjust the aluminum sheet m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com