SAGD horizontal well system

A horizontal well, the first flow technology, applied in the direction of wellbore/well components, production fluid, earthwork drilling and production, etc., can solve the problem that SAGD well cannot realize on-demand steam injection, so as to improve net profit and accurately measure gas injection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] It should be noted that the embodiments in the present application and the features of the embodiments may be combined with each other in the case of no conflict. The present invention will be described in detail below with reference to the accompanying drawings and in conjunction with the embodiments.

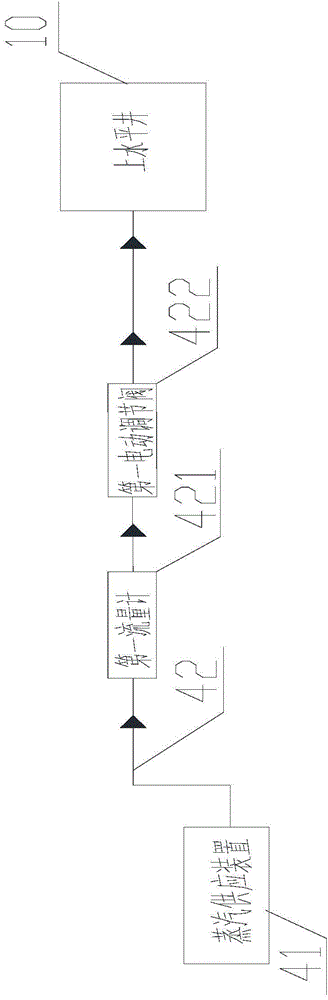

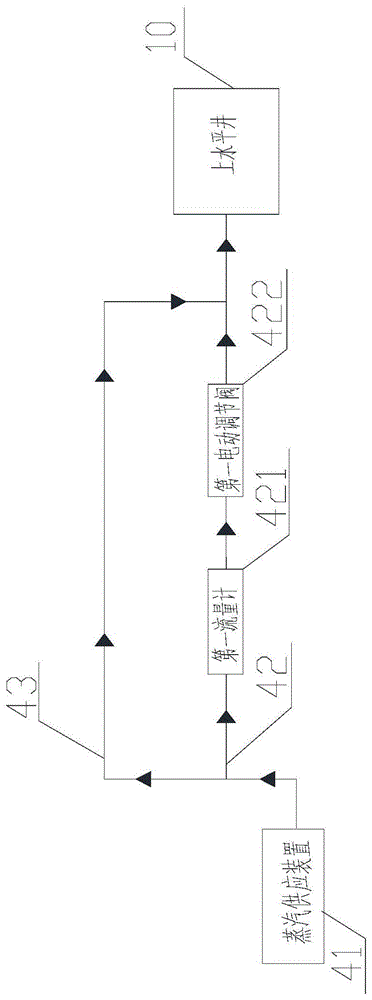

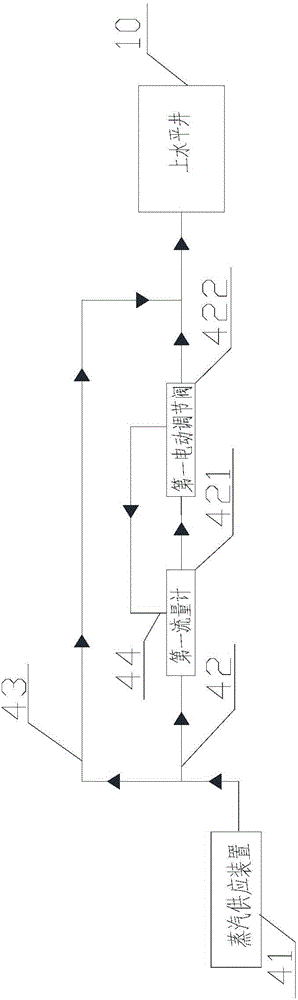

[0037] As introduced in the background section, there is a problem in the prior art that the on-demand steam injection of SAGD wells cannot be achieved. To solve this problem, an exemplary embodiment of the present invention provides a SAGD horizontal well system, such as figure 1 As shown, it includes two horizontal wells, and the two horizontal wells are the upper horizontal well 10 and the lower horizontal well 20, the SAGD horizontal well system also includes a steam control device, and the steam control device includes a steam supply device 41 and a first delivery pipeline 42, One of the upper horizontal well 10 and the lower horizontal well 20 is communicated wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com