Engine pressure lubricating system and engine with same

A technology for lubricating systems and engines, applied in pressure lubricants, pressure lubrication of lubricating pumps, lubricating parts, etc., can solve problems such as inaccessibility of lubricating oil, abnormal wear of crankshaft, affecting lubrication, etc., to achieve good oil absorption effect and reduce Oil absorption resistance and the effect of improving flow conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

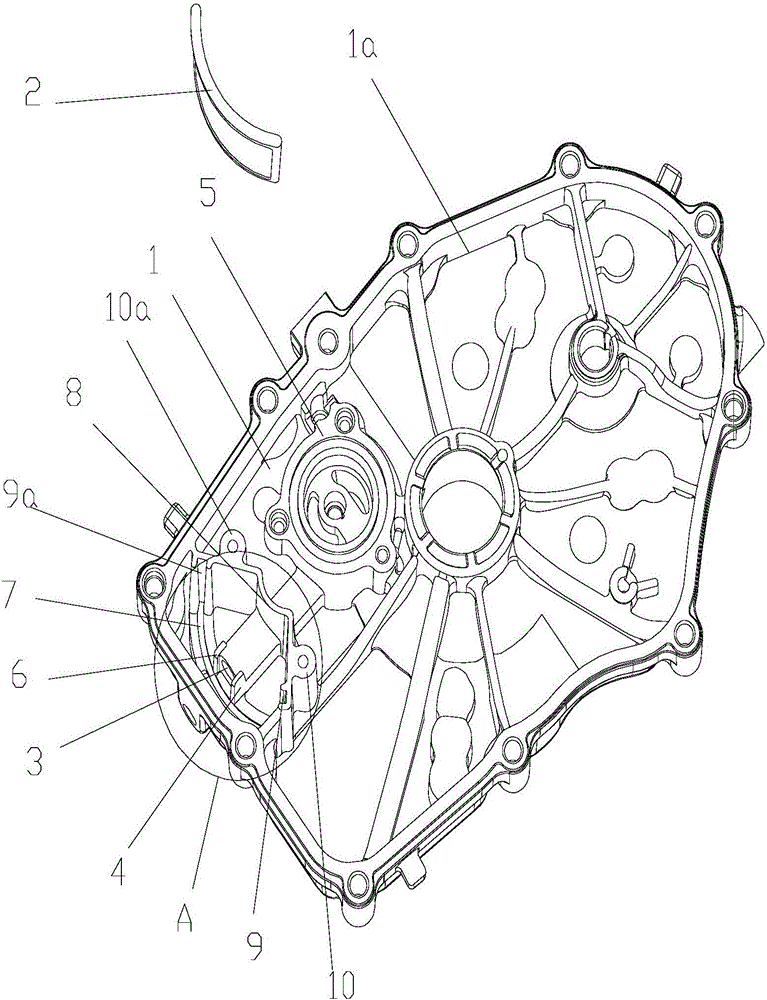

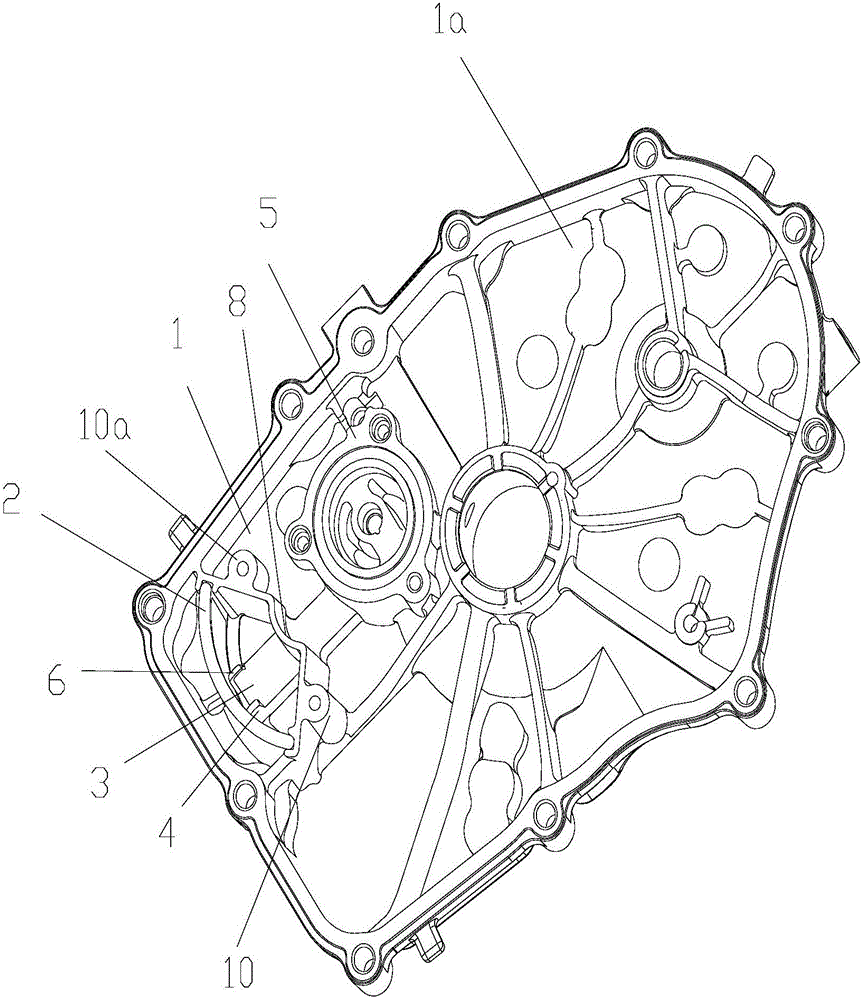

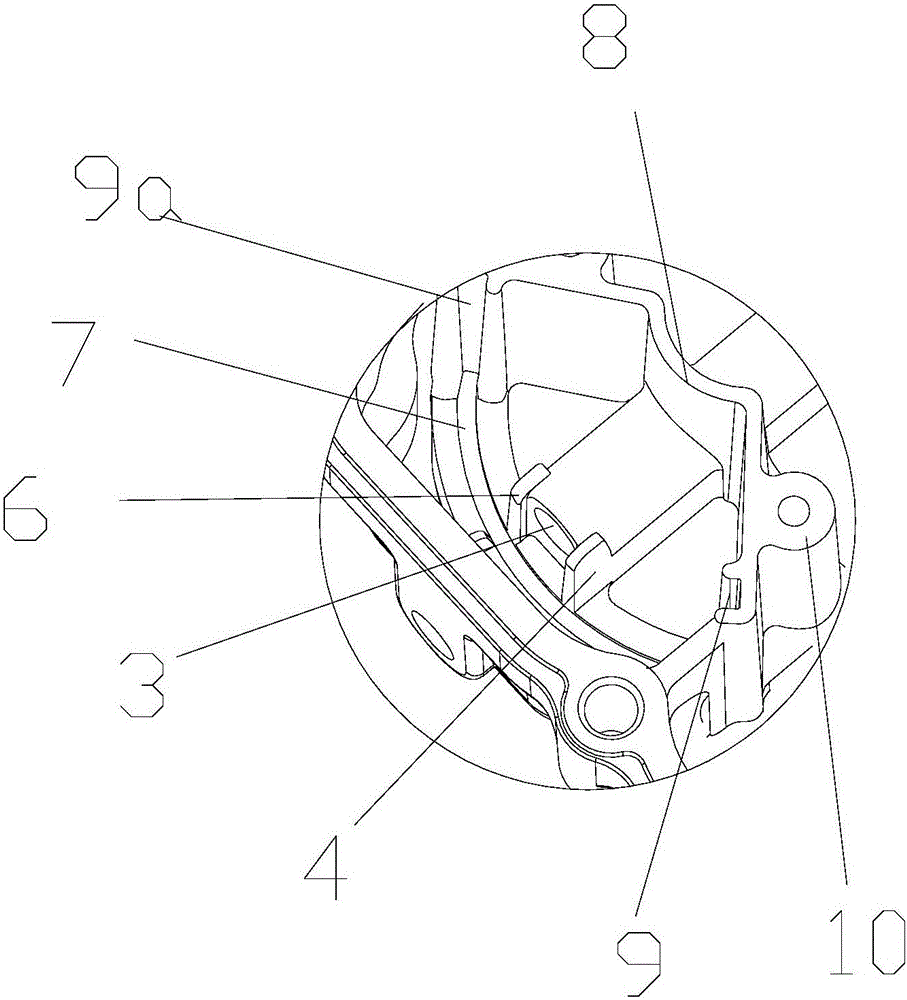

[0020] figure 1 It is a schematic diagram of the structure of the present invention before the installation of the oil filter screen, figure 2 It is a schematic diagram of the structure of the present invention after the oil filter is installed, image 3 for figure 1 The enlarged view at A, as shown in the figure: the engine pressure lubrication system of this embodiment includes an oil pump and an oil inlet channel arranged on the oil pump housing 1 of the oil pump, an oil filter screen 2 is arranged on the oil inlet channel, and the oil pump housing 1 is also provided with retaining ribs for supporting the oil filter screen 2 in the oil suction direction of the oil pump (retaining ribs 4 and 6 in the figure); wherein, the oil inlet channel of the oil pump is used for lubricating oil to enter under the suction of the oil pump, The oil filter 2 is set on the oil inlet channel of the oil pump to filter the lubricating oil, and the oil filter 2 is blocked in the direction of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com