Suction valve cover and suction assembly containing the same

A technology of suction valve and valve, which is applied in the field of anesthesia machines, can solve problems such as poor sealing, air leakage of the suction valve cover, and high product scrap rate, so as to save processing costs, avoid safety accidents, and The effect of process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

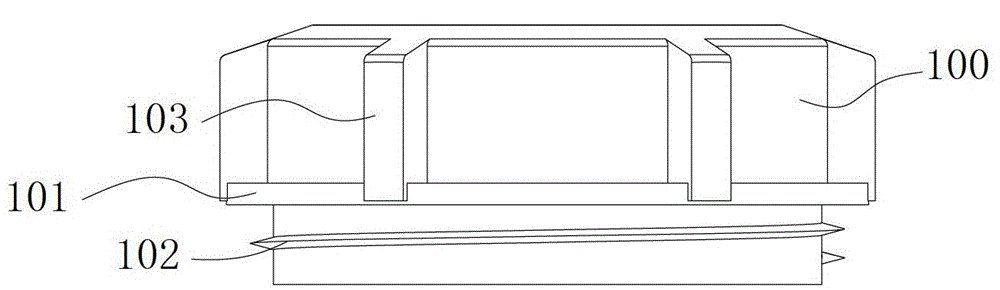

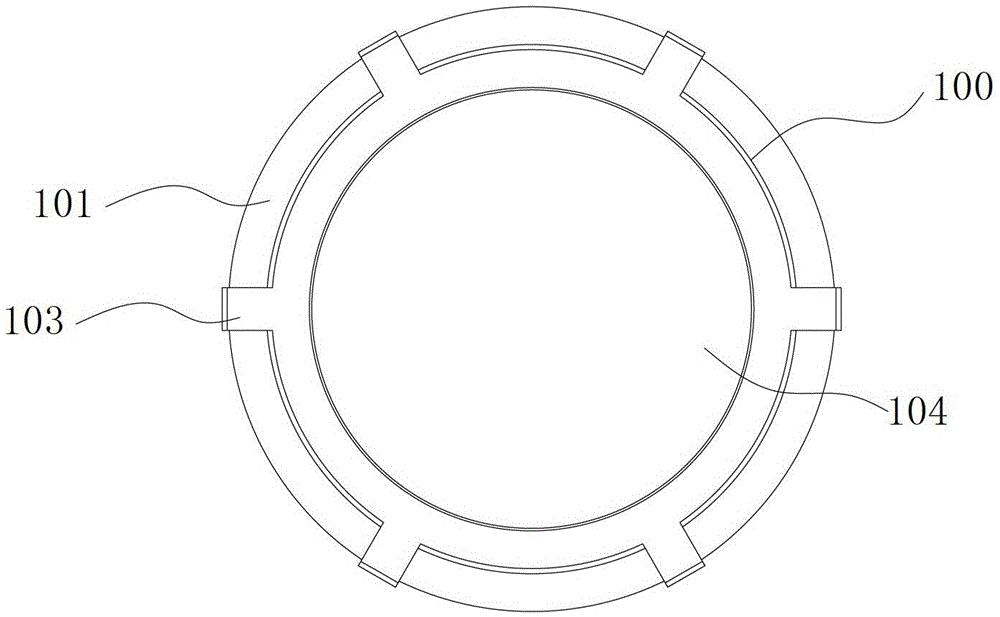

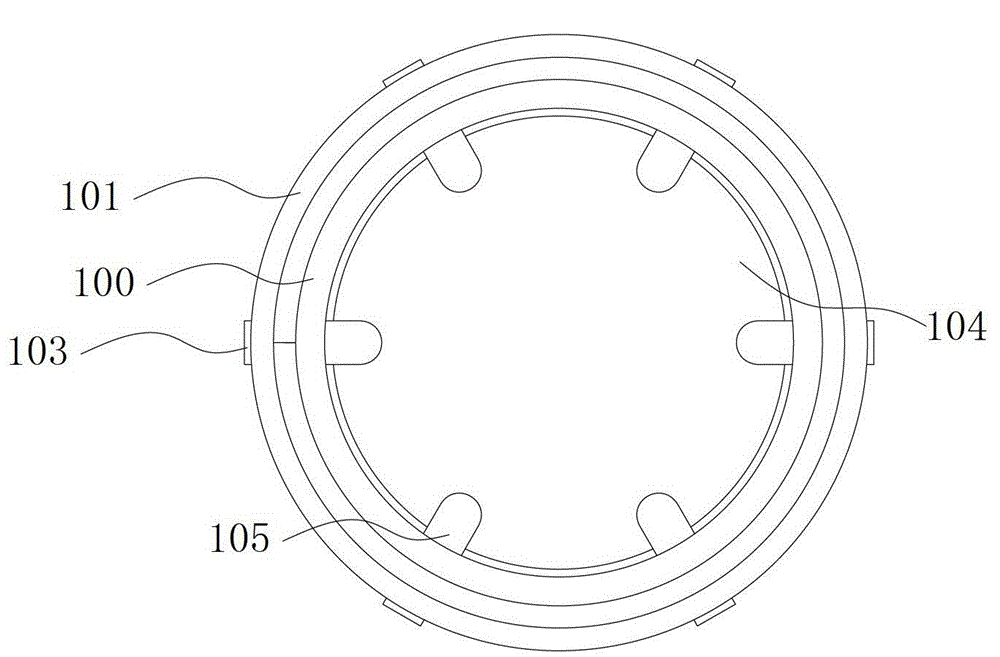

[0071] Such as Figure 5-6 As shown, the suction valve cover in this embodiment includes a valve cover body, and the valve cover body includes a circular outer wall 11, and the outer wall 11 includes a sealed outer wall first end and an open outer wall second end , the first end of the outer wall is provided with a sealing surface 13, and a connecting hole 14 is provided through the center of the sealing surface 13, so that the inside and outside of the valve cover body are connected.

[0072] The connecting hole 14 includes a first end of the connecting hole and a second end of the connecting hole. The first end of the connecting hole is arranged on the upper part of the sealing surface 13, and the second end of the connecting hole is arranged on the lower part of the sealing surface 13 (that is, inside the outer wall 11). The two ends protrude toward the second end of the outer wall with an annular inner wall 12 .

[0073] The sealing surface 13 is arc-shaped, and the seali...

Embodiment 2

[0092] The suction valve cover in this embodiment includes a valve cover body, the valve cover body includes a square outer wall, the outer wall includes a sealed first end of the outer wall and an open second end of the outer wall, and the first end of the outer wall is provided with The sealing surface is provided with a connecting hole in the center of the sealing surface, so that the inside and outside of the valve cover body are connected.

[0093] The connecting hole includes a first end of the connecting hole and a second end of the connecting hole. The first end of the connecting hole is set on the upper part of the sealing surface, and the second end of the connecting hole is set on the lower part of the sealing surface (that is, inside the outer wall), and the second end of the connecting hole faces the outer wall. The second end protrudes from a square inner wall.

[0094] The sealing surface is arc-shaped, and the sealing surface is connected with the outer wall an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com