Quick-closing valves for water hammer pressure generation

A pressure and valve technology, applied in the field of liquid rocket engine test and measurement, can solve the problems of affecting and affecting the accuracy of water hammer pressure measurement data, unable to truly reflect the dynamic characteristics of the water hammer pressure sensor, etc., so as to improve the valve closing speed and fast closing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

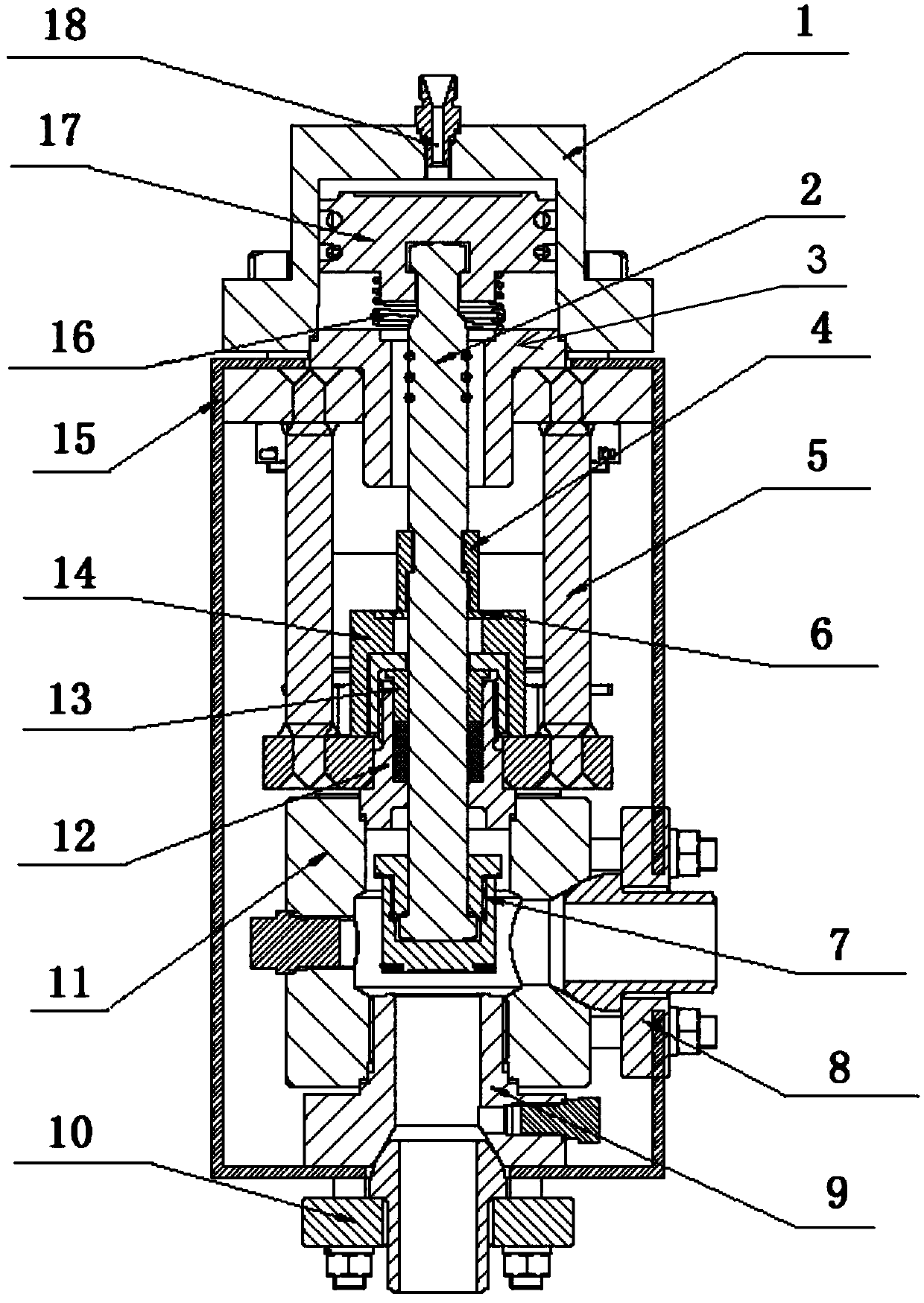

[0031] like figure 1 As shown, the quick-closing valve for water hammer pressure generation provided by the present invention includes a valve body, a driving mechanism arranged at the upper end of the valve body, a brittle fracture assembly arranged between the driving mechanism and the valve body, and a valve for protecting the valve. Sheath 15 for body and brittle fracture components.

[0032] The valve body is a cut-off valve structure, including a housing 11, a valve stem 2, a valve head 7, a valve seat 9, an inlet flange 10, an outlet flange 8, and a stuffing box 12 that acts as a seal between the valve stem 2 and the lower part of the brittle fracture assembly. and sealing pair 13;

[0033] The driving mechanism is a pneumatic structure, including a control air port 18, a driving chamber 1, a piston 17, a return spring 16, and a base 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com