Double-peak-voltage holding high-speed solenoid valve drive circuit

A high-speed solenoid valve and drive circuit technology, applied in the direction of electromagnets, electromagnets with armatures, valve details, etc., can solve the problem of poor discharge of the induced voltage of the low-end drive circuit, affecting the life of the low-end drive circuit, not applicable High-frequency applications and other problems, to achieve the effect of solving the problem of poor induction voltage discharge, realizing multi-channel solenoid valve driving, and reducing the load of microprocessors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The concrete implementation of the present invention will be further described below in conjunction with accompanying drawing:

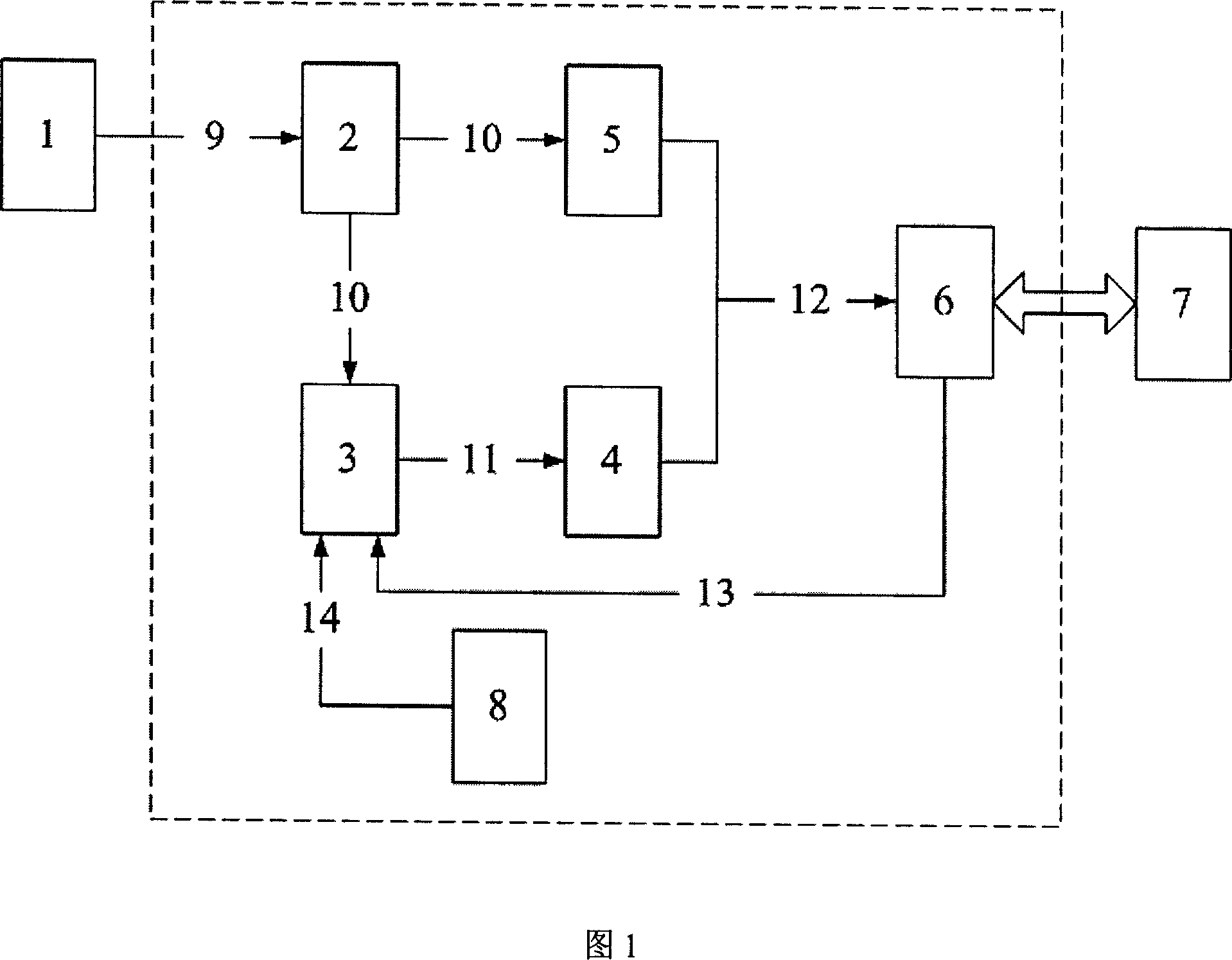

[0030] Figure 1 shows the structural block diagram of the dual-voltage peak hold high-speed solenoid valve drive circuit. The structure shown in the dotted line box is the structure of the device, including the isolation circuit 2, the high-end current limiting circuit 3, the high-end drive circuit 4, and the low-end drive circuit. Circuit 5, peak removal and current detection circuit 6 and peak current setting circuit 8. The input end of the isolation circuit 2 is connected to the output end of the valve controller 1, and its output end is the isolated valve control pulse, which is respectively connected to the input ends of the high-end current limiting circuit 3 and the low-end drive circuit 5; the high-end current limiting circuit 3 The output end of the circuit is connected with the high-end drive circuit 4, and outputs a high level when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com