Petroleum pipeline bracket device

A technology for oil pipelines and support devices, which is applied in the direction of pipeline supports, pipes/pipe joints/fittings, mechanical equipment, etc., which can solve the problems of inconvenient pipeline erection and installation, broken oil pipeline supports, oil pipeline supports without lifting and lateral adjustment functions, etc. problems, to prevent breakage and ensure smooth flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

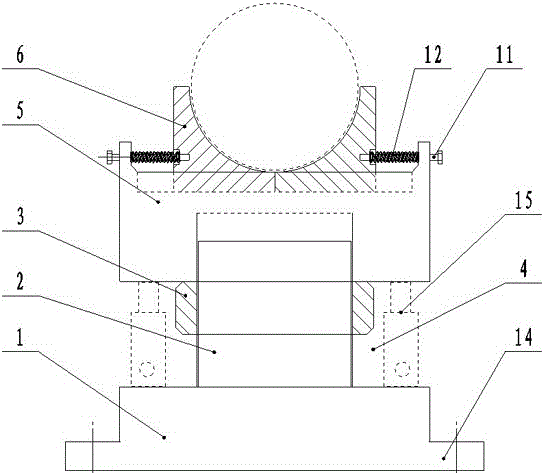

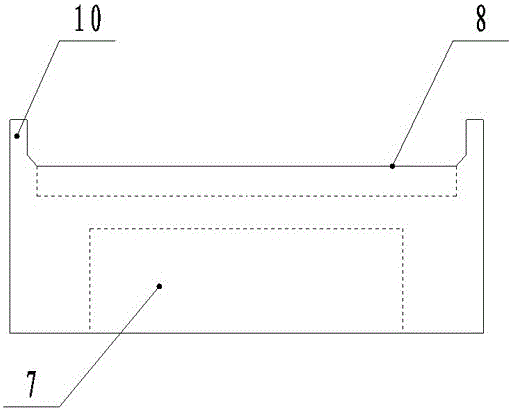

[0020] Such as Figure 1-3 As shown, a kind of petroleum pipeline support device of the present invention comprises pipeline support base 1, lift screw rod 2, lift nut 3, support seat 5 and pipeline stop block 6, and lift screw rod 2 is arranged on pipeline support base 1 to oil The pipe bracket acts as a general support, the lifting nut 3 is threaded and sleeved on the lifting screw 2, the lower end of the support seat 5 is provided with a supporting groove 7, and the supporting groove 7 is also set on the lifting screw 2, and the lifting nut 3 is lifted and lowered by rotating the lifting nut 3. The support seat 5; the upper end of the support seat 5 is provided with the installation chute 8 of the pipe limit block 6, and the two pipe stop blocks 6 are symmetrically arranged in the chute 8; the pipe support base 1 and the support seat 5 are arranged There is a jack installation port 4.

[0021] During use, the bottom of the pipeline support base 1 is provided with a bolt fi...

Embodiment 2

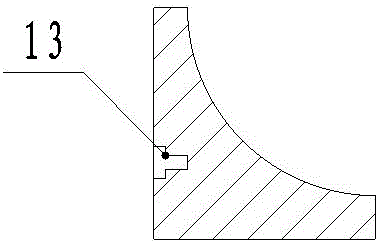

[0023] Such as image 3 As shown, an oil pipeline support device of the present invention, on the basis of Embodiment 1, limit block adjustment platforms 10 are arranged on both sides of the support seat 5, and horizontal screw holes are arranged on the limit block adjustment platform 10, and the screw holes are provided with limited Position block adjustment column 11, limit block adjustment column 11 can spirally rotate in the screw hole, and a nut clamped by a handle is also arranged at the outer end of limit block adjustment column 11, and limit block adjustment column 11 adjusts the pipeline limit Block 6 moves in chute 8 . A buffer spring 12 is sheathed on the limit block adjusting column 11 , and both ends of the buffer spring 12 are squeezed on the limit block adjusting table 10 and the pipeline limit block 6 respectively. A T-shaped hole 13 is arranged on the pipe limit block 6 corresponding to the limit block adjustment column 11, the buffer spring 12 is squeezed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com