machine tool

A technology of machine tools and connecting mechanisms, which is applied in the direction of metal processing machinery parts, manufacturing tools, positioning devices, etc., can solve problems such as complex composition, and achieve the effect of simplified composition and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0030] Hereinafter, the first embodiment will be described with reference to the drawings.

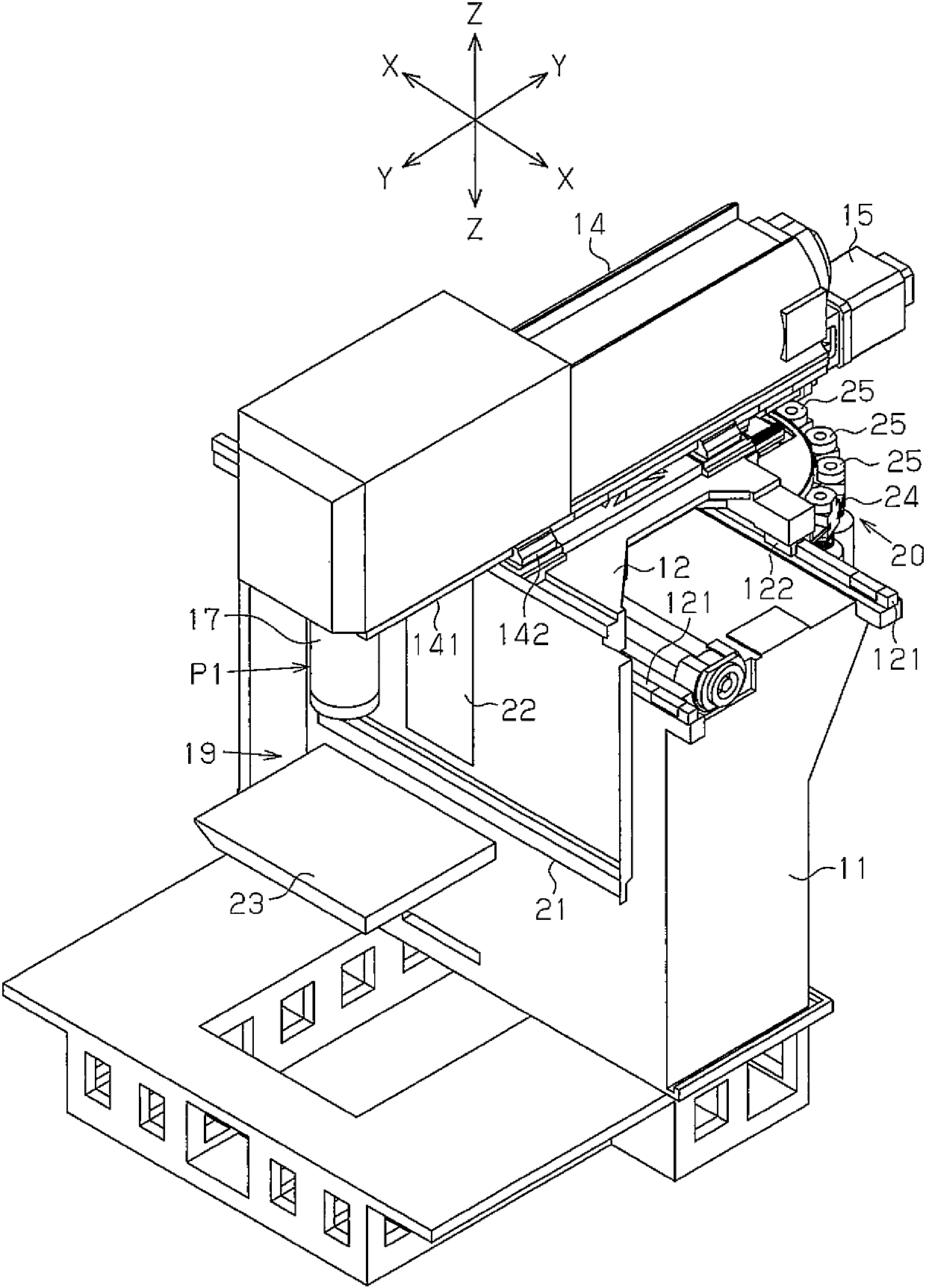

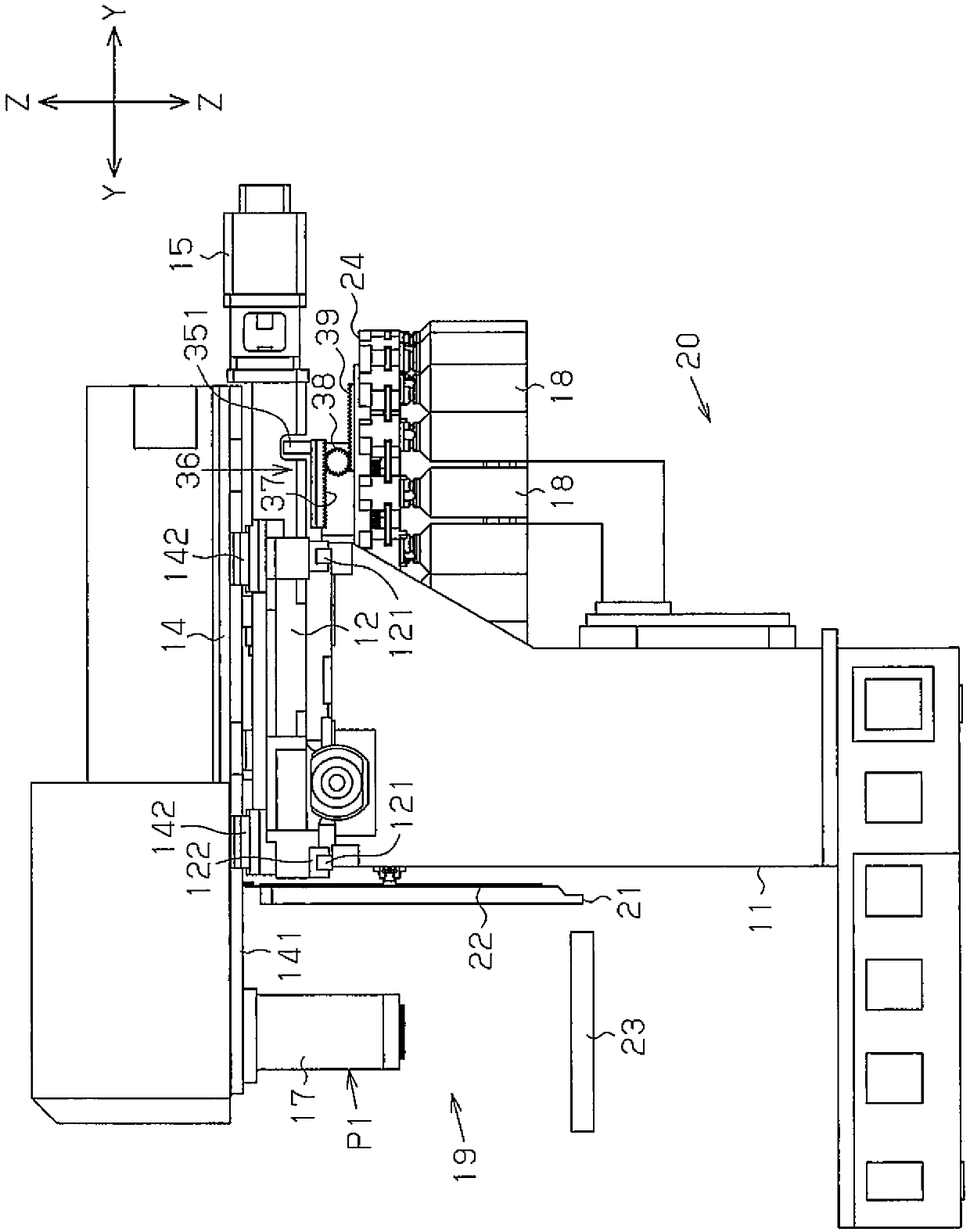

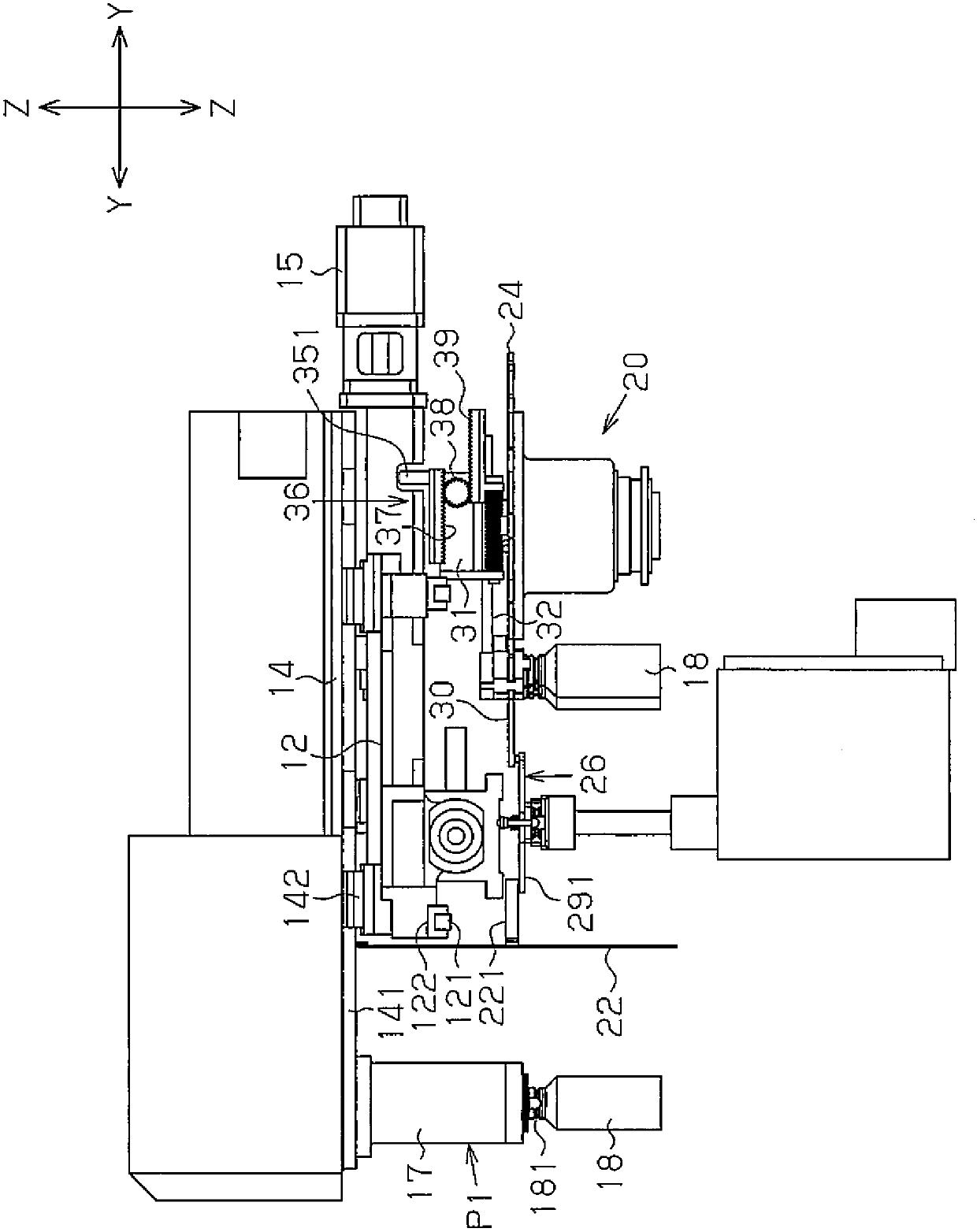

[0031] like Figure 1 ~ Figure 4 As shown, the X-axis moving table 12 is supported on the machine table 11 of the machine tool. The X-axis moving table 12 can move in the X-axis direction along the rail 121 in the horizontal plane by an X-axis moving motor (not shown). A Y-axis moving table 14 is supported on the X-axis moving table 12 . The Y-axis moving table 14 can move in the Y-axis direction in the horizontal plane along the rail 141 by the Y-axis moving motor 15 . That is, if Figure 4 As shown, a screw shaft 151 is connected to the output shaft of the Y-axis moving motor 15 capable of forward and reverse rotation. An internally threaded body 143 as a driving body is screwed onto the screw shaft 151 . The internal thread body 143 is fixed on the lower surface of the Y-axis moving table 14 . Therefore, when the internally threaded body 143 is reciprocated in the Y-axis direc...

no. 2 Embodiment approach

[0059] Next, based on Figure 11 to Figure 15 , the second embodiment will be described focusing on the parts different from the first embodiment. In the second embodiment, even if the shape, position, etc. of the members with the same reference numerals as those of the first embodiment are different from those of the first embodiment, they have the same characteristics as those of the first embodiment. Components with the same reference numbers and the like have the same function.

[0060] like Figure 11 and Figure 12 As shown, the vertical relationship between the X-axis moving table 12 and the Y-axis moving table 14 is opposite to that of the first embodiment. That is, the slider 142 of the Y-axis moving table 14 is supported on a rail 141 extending in the Y-axis direction on the machine table 11 . In addition, a slider 122 of the X-axis moving table 12 is supported on a rail 121 extending in the X-axis direction on the Y-axis moving table 14 . In the second embodime...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap