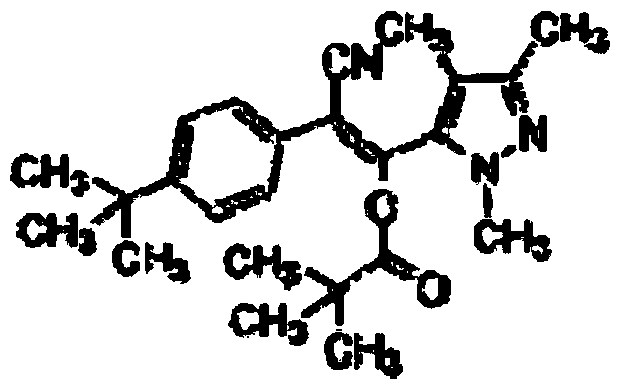

A kind of pesticide composition containing pyraclofen and its application

A technology of fenpyroxifen and a composition, which is applied to the field of insecticidal and acaricidal compositions containing fenpyroximate, and the field of insecticidal and acaricidal compositions, which can solve the problem that the plant tolerance and activity of the acaricide cannot meet the needs, etc. To reduce the risk of resistance, slow down the generation of mite resistance, and improve tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

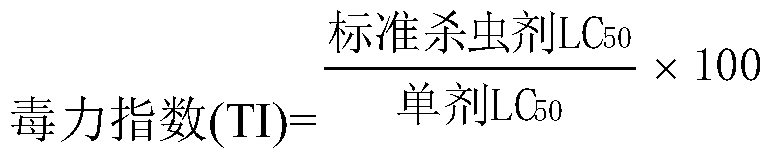

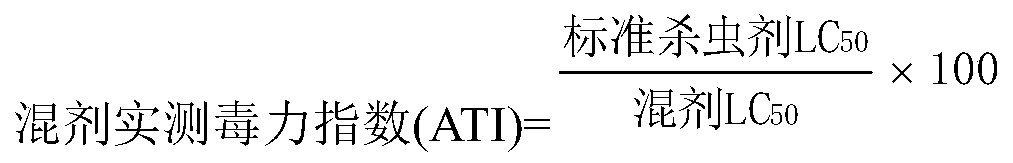

Method used

Image

Examples

Embodiment 1

[0124] Example 1: 6% pyridofen-carboxyphenidate (1+5) ultra-low volume liquid

[0125] Weigh 1% pyrazafen, 5% dextate, 5% fatty alcohol polyoxyethylene ether, 3% calcium dodecylbenzenesulfonate, 15% N,N-dimethylformamide, N - Methylpyrrolidone 12%, mesitylene to make up to 100%. In a reactor equipped with electric stirring, the active ingredient is first stirred and dissolved with a solvent at a stirring speed of 100 rpm, then the auxiliary ingredients are added, and the ingredients are fully stirred for 30 minutes to make it evenly mixed to obtain an ultra-low volume liquid.

Embodiment 2

[0126] Example 2: 22% pyrazafen ˙carbafen (2+20) suspension concentrate

[0127] Take by weighing 2g pyraclofen, 20g clofenate technical material, 3g alkylnaphthalenesulfonic acid polycondensate anion sulfonate, 1.5g alkylphenol polyoxyethylene polyoxyethylene polyether formaldehyde condensate sulfate, 1g white carbon black, 0.2g xanthan gum, 5g ethylene glycol, 0.2g sodium benzoate, 0.5g organic silicon, add water to make up to 100g. Add the above-mentioned raw materials into a high-shear emulsifier and shear for 10 minutes, and then grind them with a sand mill to obtain a suspending agent.

Embodiment 3

[0128] Example 3: 44% pyrazafen ˙carbafen (40+4) water dispersible granules

[0129] Take by weighing 40g pyrazafen, 4g clofenate, the sodium salt of 4g alkylnaphthalenesulfonic acid polycondensate, 2g alkylnaphthalenesulfonate and anionic wetting agent mixture, 0.2g sodium benzoate, 19g ammonium sulfate and 15g cornstarch. Mix evenly, after jet crushing, granulate in a granulator, then dry and sieve to obtain granular products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com