Membrane adhering device for glass

A film sticking device and glass technology, which is applied in the direction of packaging material feeding device, packaging, transportation packaging, etc., can solve the problems of high labor intensity and high cost, and achieve the effects of reducing labor intensity, solving low efficiency, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below by means of specific embodiments:

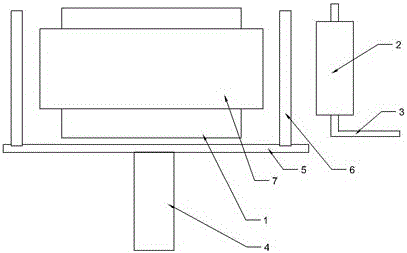

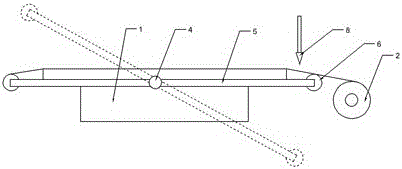

[0013] The reference signs in the drawings of the description include: processing table 1 , protective film reel cover 2 , bracket 3 , rotating shaft 4 , support arm 5 , film sticking rod 6 , glass 7 , and cutter 8 .

[0014] The embodiment is basically as attached figure 1 , attached figure 2 Shown: The film sticking device for glass, including the processing table 1 and the film sticking mechanism, in order to ensure that the protective film is completely pasted on the glass 7, the width of the processing table 1 is designed to be smaller than the width of the glass 7 to be processed, so that it can avoid the process of film sticking , the protective film and the processing table 1 have adhesion phenomenon.

[0015] One side of the processing table 1 is oppositely provided with a support 3 for installing the protective film reel. ” on the bracket 3. The film sticki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com