Automatic lifting device for gluing and potting

An automatic lifting and potting technology, which is applied in the direction of lifting devices, lifting frames, etc., can solve the problems that restrict the improvement of the automation degree of the automatic filling and sealing production line of glue coating, filling and sealing, difficult automatic control of the production line, and complicated transmission mechanism, etc., to achieve The effect of stable lifting, high lifting efficiency and simple transmission mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

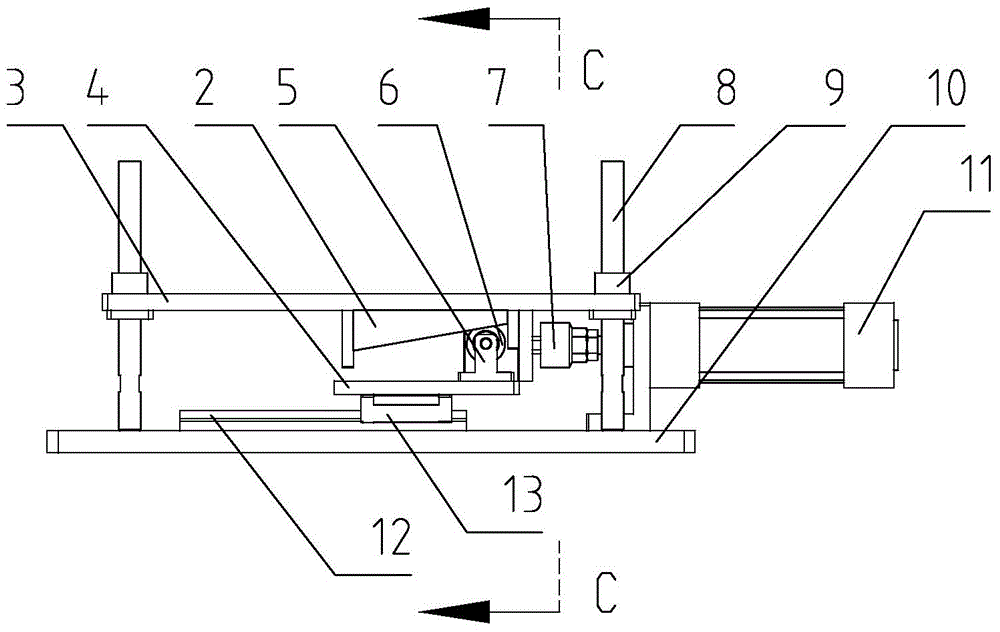

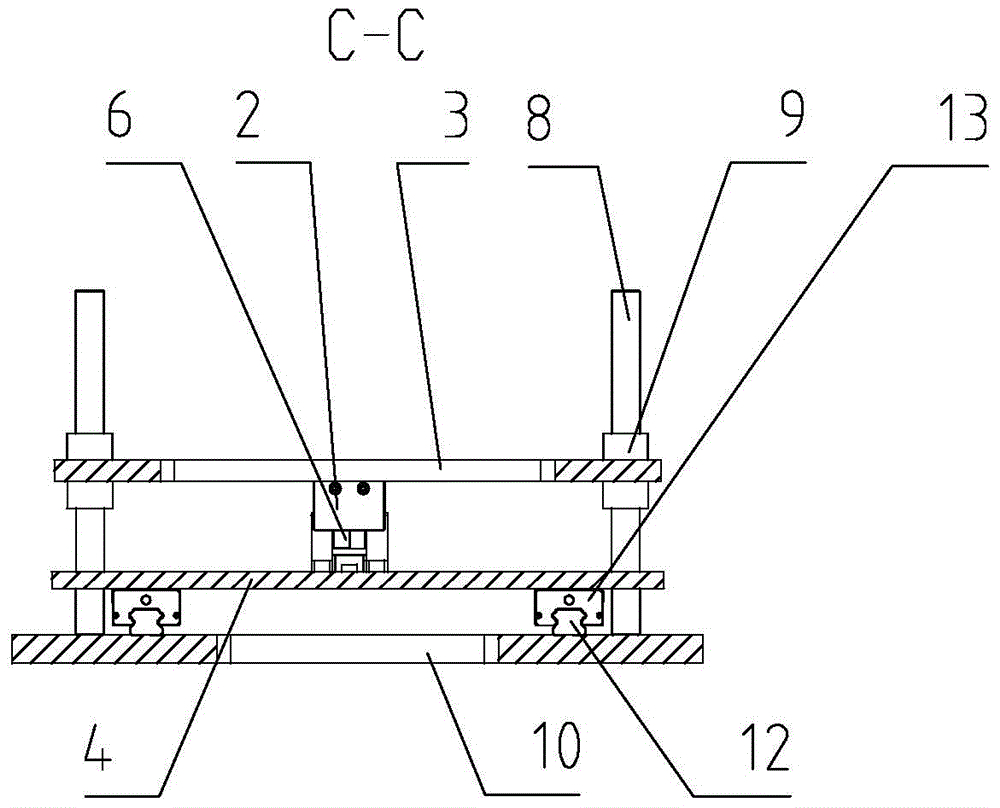

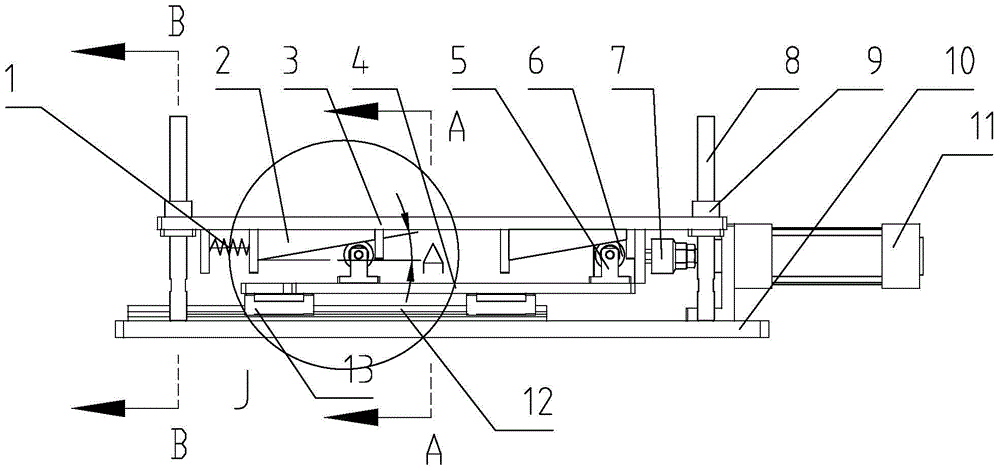

[0028] Such as figure 1 , figure 2 Shown, is an embodiment of the present invention, is provided with base 10, is fixedly provided with vertical lifting shaft 8 on base 10, is provided with linear bearing 9 on vertical lifting shaft 8, is provided with working platform 3 above base 10, and working platform 3. It is fixedly connected with the outer ring of the linear bearing 9 on the vertical lifting shaft 8. A parallel thrust plate 4 is also provided on the base 10. A sliding connection device is provided between the parallel thrust plate 4 and the base 10. figure 1 It can be seen that the sliding connection device provided between the parallel thrust plate 4 and the base 10 is fixed on the base 10 with a linear guide rail 12, the linear guide rail 12 is slidingly connected with the linear guide rail seat 13, and the linear guide rail seat 13 is connected with the parallel The thrust plate 4 is fixedly connected, and the linear guide rail 12 has a simple structure, is conven...

Embodiment 2

[0032] Such as image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 As shown, it is another embodiment of the present invention. The difference between this embodiment and Embodiment 1 is that there are four wedge-shaped lifting thrust seats 2 at the bottom of the working platform 3, which are respectively located on the four outer peripheries of the bottom of the working platform 3. In this way, the working platform 3 can be supported stably, which is more suitable for the lifting of heavy parts. Two of the four wedge-shaped lifting thrust seats 2 are slidingly connected with the bottom surface of the working platform 3. The two wedge-shaped lifting thrust seats 2 are provided with a tension spring 1 on one side, and the tension force of the top tension spring 1 can satisfy the sliding connection between the wedge-shaped lifting seat 2 and the rollers, and can also ensure that during the lifting movement of the working platform, the mechanical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com