A kind of m65 resistance welded petroleum casing and its manufacturing method

A technology for oil casing and electric resistance welding, applied in the field of steel for oil casing, can solve the problems of poor weldability and impact toughness, high carbon and manganese content, and achieve the effects of good weldability, low tempering temperature and consistency guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

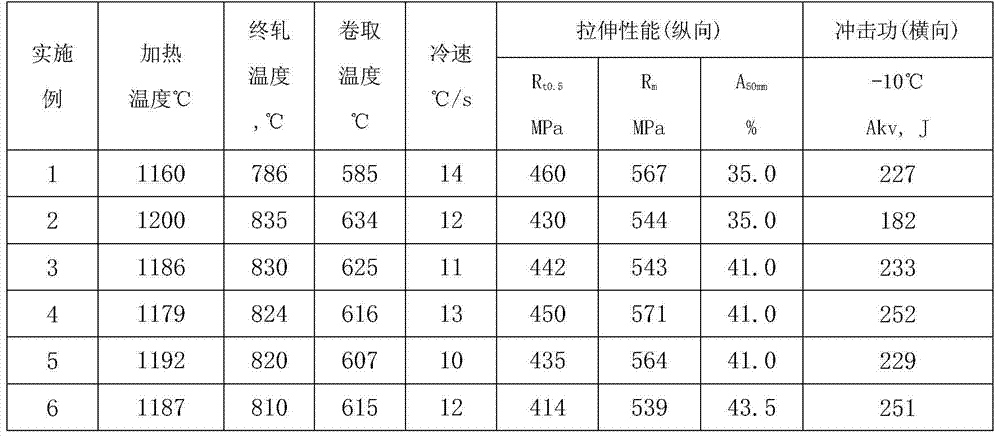

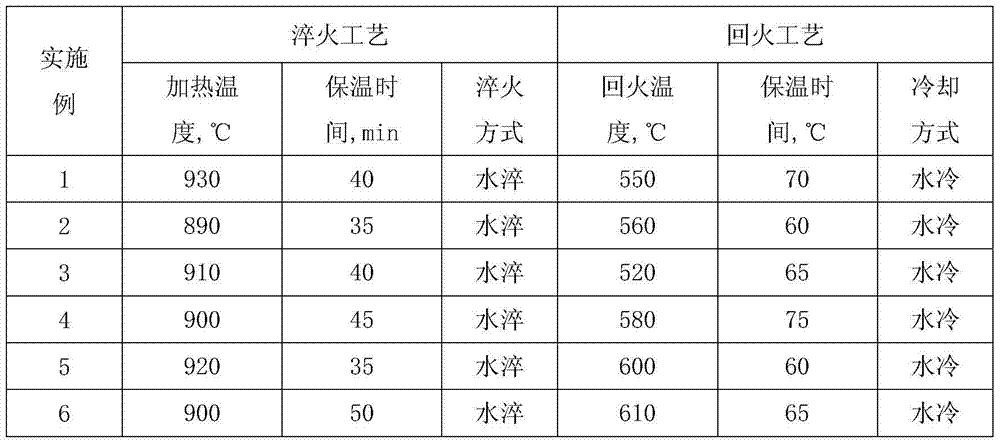

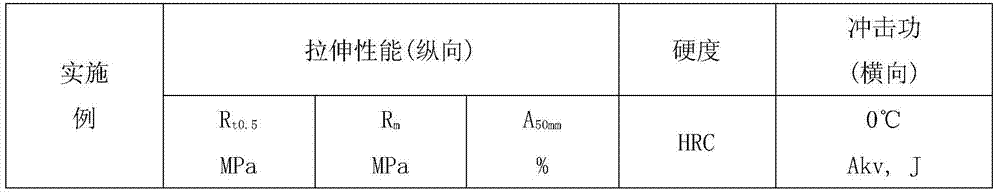

Examples

Embodiment Construction

[0028] The chemical composition of the present invention is proportioned as follows by weight percentage: C: 0.13%-0.17%, Si: 0.15%-0.30%, Mn: 0.80%-1.20%, P: ≤0.020%, S: ≤0.008%, Cr: 0.30%-0.40%, Ti: 0.010%-0.030%, Als: 0.02%-0.05%, N: ≤0.008%, and the rest are Fe and unavoidable elements.

[0029] The present invention adopts the following production process, which includes molten iron pretreatment, molten steel smelting, refining outside the furnace, continuous casting of slab, reheating of continuous casting slab, rolling, cooling, coiling, ERW pipe making and heat treatment of the whole pipe. The specific process is as follows :

[0030] 1) Smelting and continuous casting process: molten iron pretreatment, converter smelting - through top blowing or top-bottom composite blowing, refining outside the furnace, LF furnace desulfurization treatment and calcium treatment to control the shape of inclusions and improve the ductility, toughness and Cold bending performance, cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com