Drain pump

A drainage pump and vane technology, which is applied in the direction of pumps, pump components, pump devices, etc., can solve the problems of drainage pump noise, increased vibration, and easy water entry, etc., to achieve vibration and noise suppression, vibration and noise reduction, and discharge capacity Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

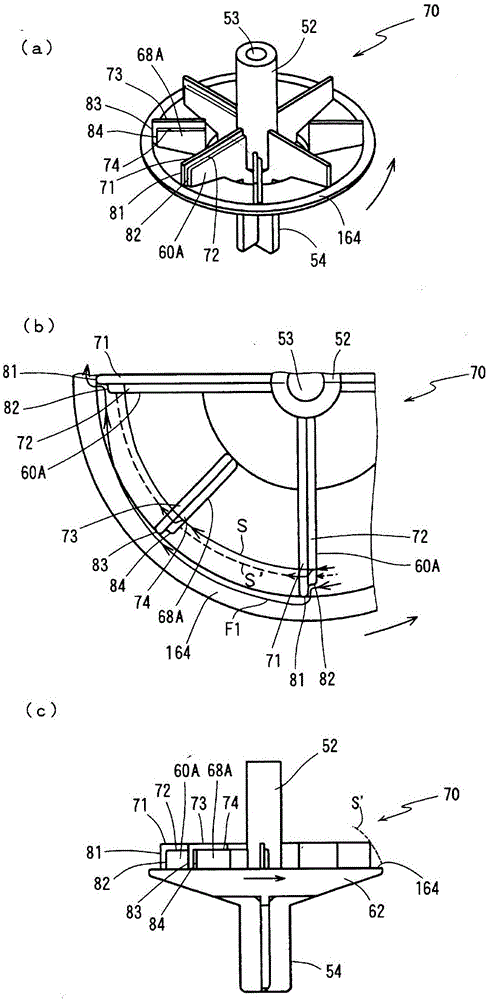

[0066] figure 1 It is a figure which shows an example of the rotary vane used for the drainage pump of this invention, figure 1 (a) is a perspective view showing the whole rotating blade, figure 1 (b) is to figure 1 A top view of a partially enlarged representation of the rotating blade shown in (a), figure 1 (c) is figure 1 (a) Front view of the rotating blade shown. In the description of the embodiment of the present invention, for the Figure 17 shown in previous rotary blades and Figure 4 Common configurations of the rotating blades of the comparative example shown are denoted by the same reference numerals, and detailed description thereof will be omitted. In addition, symbols 60A and 68A are given to the large-diameter blades and the auxiliary blades of the rotary blade 70 in this embodiment.

[0067] exist figure 1 In the rotary vane 70 of the shown drain pump, a stepped portion 72 is provided on the upper edge portion 71 of the edges of the large-diamete...

no. 2 Embodiment

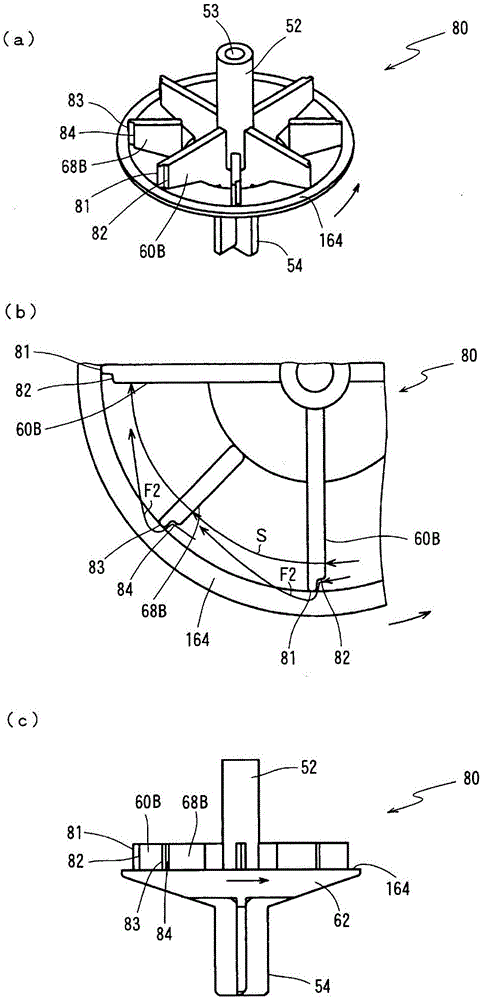

[0070] figure 2 It is a figure which shows another example of the rotary vane used for the drainage pump of this invention, figure 2 (a) is a perspective view showing the whole rotating blade, figure 2 (b) is to figure 2 A top view of a partially enlarged representation of the rotating blade shown in (a), figure 2 (c) is figure 2 (a) Front view of the rotating blade shown. In addition, reference numerals 60B and 68B are attached to the large-diameter blade and the auxiliary blade of the rotary blade 80 of this embodiment.

[0071] exist figure 2 In the rotary vane 80 of the illustrated drain pump, a stepped portion 82 is provided only on the outer edge portion 81 of the edge portion of the large-diameter vane 60B. In addition, the outer edge portion 83 of the auxiliary blade 68B is also provided with a stepped portion 84 . The stepped portions 82 , 84 are formed over the entire lengths of the outer edge portions 81 , 83 of the blades 60B, 68B. The stepped portio...

no. 3 Embodiment

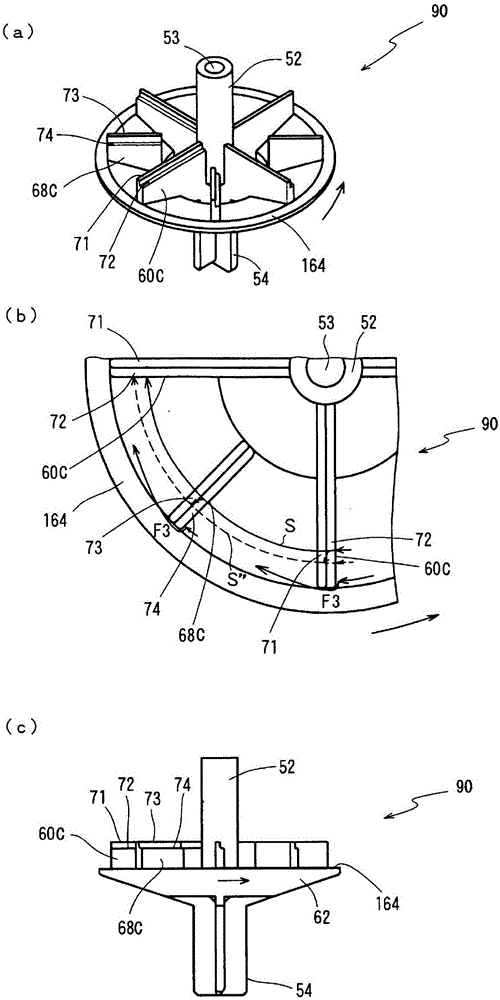

[0073] image 3 It is a figure which shows the 3rd embodiment of the rotating vane used for the drainage pump of this invention, image 3 (a) is a perspective view showing the whole rotating blade, image 3 (b) is to image 3 A top view of a partially enlarged representation of the rotating blade shown in (a), image 3 (c) is image 3 (a) Front view of the rotating blade shown. In addition, symbols 60C and 68C are assigned to the large-diameter blades and auxiliary blades of the rotary blade 90 in this embodiment.

[0074] image 3 In the rotary vane 90 of the illustrated drain pump, the upper edge portion 71 of the edge portion of the large-diameter vane 60C is provided with a stepped portion 72 . In addition, a stepped portion 74 is also provided on the upper edge portion 73 of the auxiliary blade 68C. The stepped portions 72, 74 are formed over the entire lengths of the upper end edge portions 71, 73 of the blades 60C, 68C. The steps 72 and 74 function to splash the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com