A sealing cover assembly and its production process

A production process and sealing cover technology, applied in the field of sealing cover components and its production process, can solve the problems of increasing enterprise cost expenditure, easy confusion of sealing components, damage of sealing components, etc., to achieve cost reduction, simple and reasonable production method, The effect that improves the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

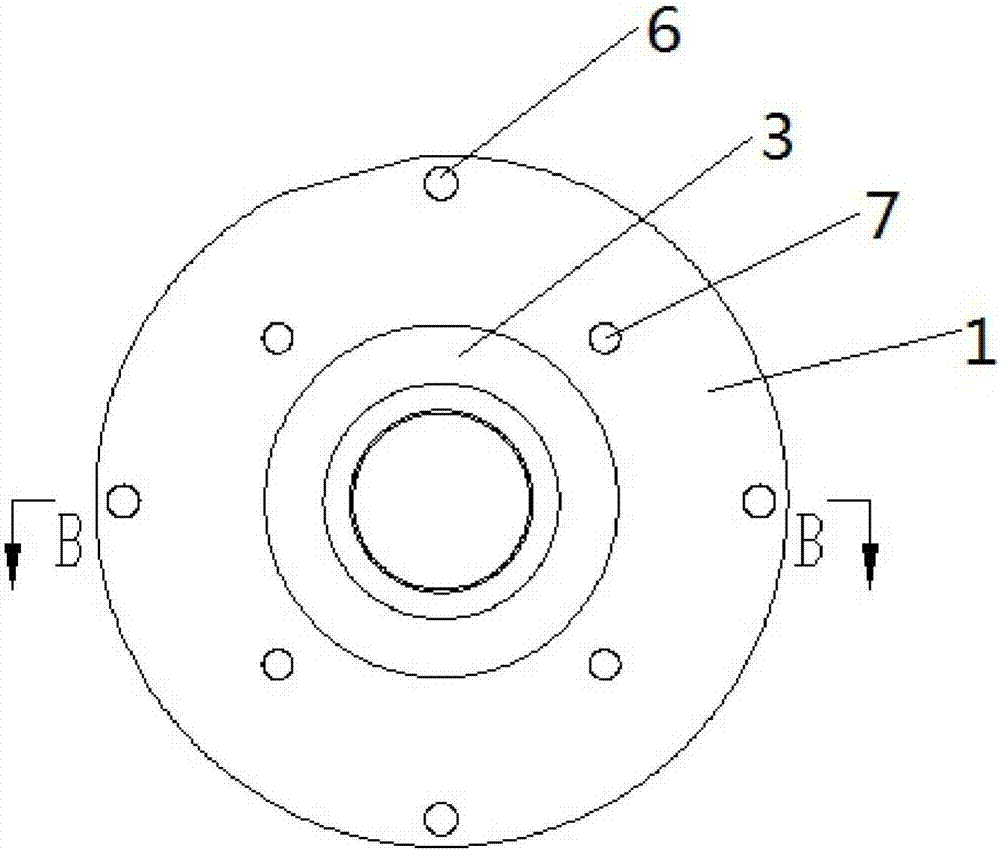

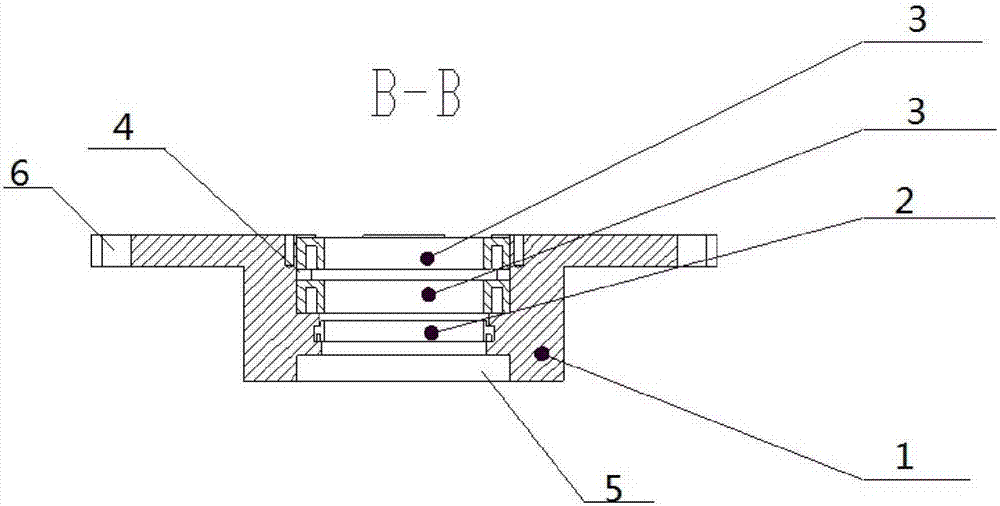

[0031] Such as figure 1 with figure 2 The seal cover assembly shown includes: a seal cover body 1, a seal ring 2 and a group of skeleton oil seals 3 are arranged inside the seal cover body 1, and the seal ring 2 is arranged under the skeleton oil seal 3 , and, a gasket 4 is provided between the two skeleton oil seals 3 .

[0032] The seal cover body 1 described in this embodiment is inwardly convex, and its bottom is provided with an inner groove 5, and the edge of the seal cover body 1 is provided with a first installation hole 6, and the inner groove 5 A rubber sleeve is provided in the middle, and the rubber sleeve matches the inner groove 5 .

[0033] The frame oil seal 3 in this embodiment is composed of a first frame oil seal and a second frame oil seal, and the first frame oil seal and the second frame oil seal are arranged above the sealing ring 2 in sequence.

[0034] The sealing ring 2 described in this embodiment is in a convex shape, and a groove is provided on...

Embodiment 2

[0039] The structure of the sealing cap assembly in the production process of the sealing cap assembly described in this embodiment is the same as that in Embodiment 1.

[0040] Such as figure 1 with figure 2 The seal cover assembly shown includes: a seal cover body 1, a seal ring 2 and a group of skeleton oil seals 3 are arranged inside the seal cover body 1, and the seal ring 2 is arranged under the skeleton oil seal 3 , and, a gasket 4 is provided between the two skeleton oil seals 3 .

[0041] The seal cover body 1 described in this embodiment is inwardly convex, and its bottom is provided with an inner groove 5, and the edge of the seal cover body 1 is provided with a first installation hole 6, and the inner groove 5 A rubber sleeve is provided in the middle, and the rubber sleeve matches the inner groove 5 .

[0042] The frame oil seal 3 in this embodiment is composed of a first frame oil seal and a second frame oil seal, and the first frame oil seal and the second f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com