Physical touch drag reduction method for pipe jacking mud

A technology of pipe jacking and mud, which is applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc. It can solve the problems of increased jacking force, failure to drop, and failure to continue, etc., to reduce jacking force and reduce Increased frictional resistance and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

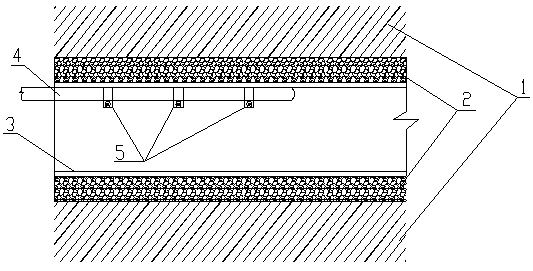

[0009] A physical touch drag reduction method for pipe jacking mud, characterized in that the thixotropic mud is mixed and configured according to the weight of raw materials, bentonite: carboxymethyl cellulose (CMC): soda ash: water = 9: 0.13:0.87:90; concrete The vibrating rod 4 is anchored on the inner wall of the jacking pipe 3 through the steel sheet 5, and clings to the pipe wall; the configured thixotropic mud is injected into the gap between the outer surface of the jacking pipe 3 and the soil body 1 to form a mud sleeve 2. The vibration frequency of the concrete vibrating rod 4 is 2200-2500hz.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com