A kind of waste tire rubber powder rubber asphalt segregation test and evaluation method

A technology of waste tire rubber powder and rubber asphalt, which is applied in the field of waste tire rubber powder rubber asphalt segregation test and evaluation, can solve the unsolvable problems of how to deal with waste tire rubber powder and rubber asphalt, so as to facilitate correct guidance of construction, easy to master, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with embodiment the present invention is described in further detail.

[0028] Example conditions: the design content of waste tire rubber powder in rubber asphalt is 20%. After production, it will be transported 700km for 24 hours to the asphalt mixing plant. The temperature of waste tire rubber powder rubber asphalt will drop from 200°C to 160°C, and segregation has occurred, use the method of the present invention to determine whether it can be used directly.

[0029] A kind of waste tire rubber powder rubber asphalt segregation test and evaluation method, the method comprises the following steps:

[0030] The first step is to draw the standard density map of waste tire rubber powder rubber asphalt:

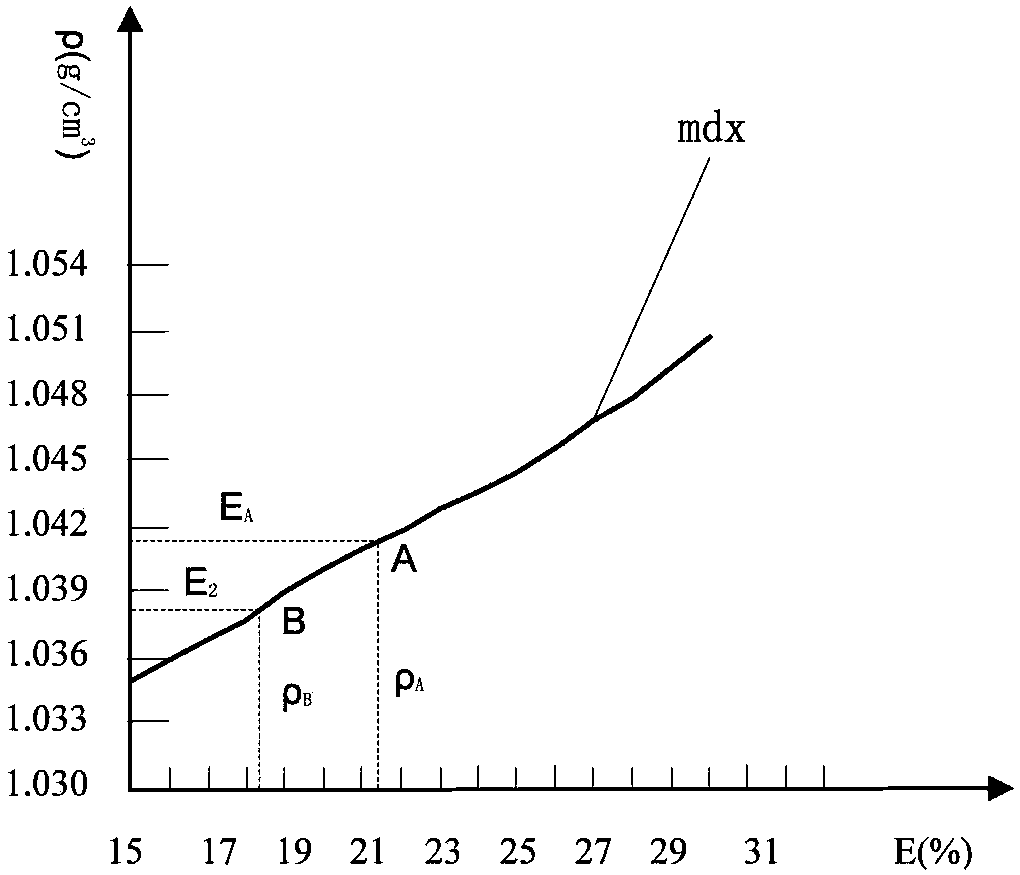

[0031] Draw a standard density map of waste tire rubber powder rubber asphalt before mass production, see figure 1 , the waste tire rubber asphalt is produced in the laboratory, the materials and production process are the same as those in mass pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com