Electronic component testing device

A technology of electronic components and detection devices, which is applied in the field of electronic component detection devices, can solve the problems of incoherent operation, non-compliance with production inspection process, time-consuming and other problems, and achieve the effect of coherent operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

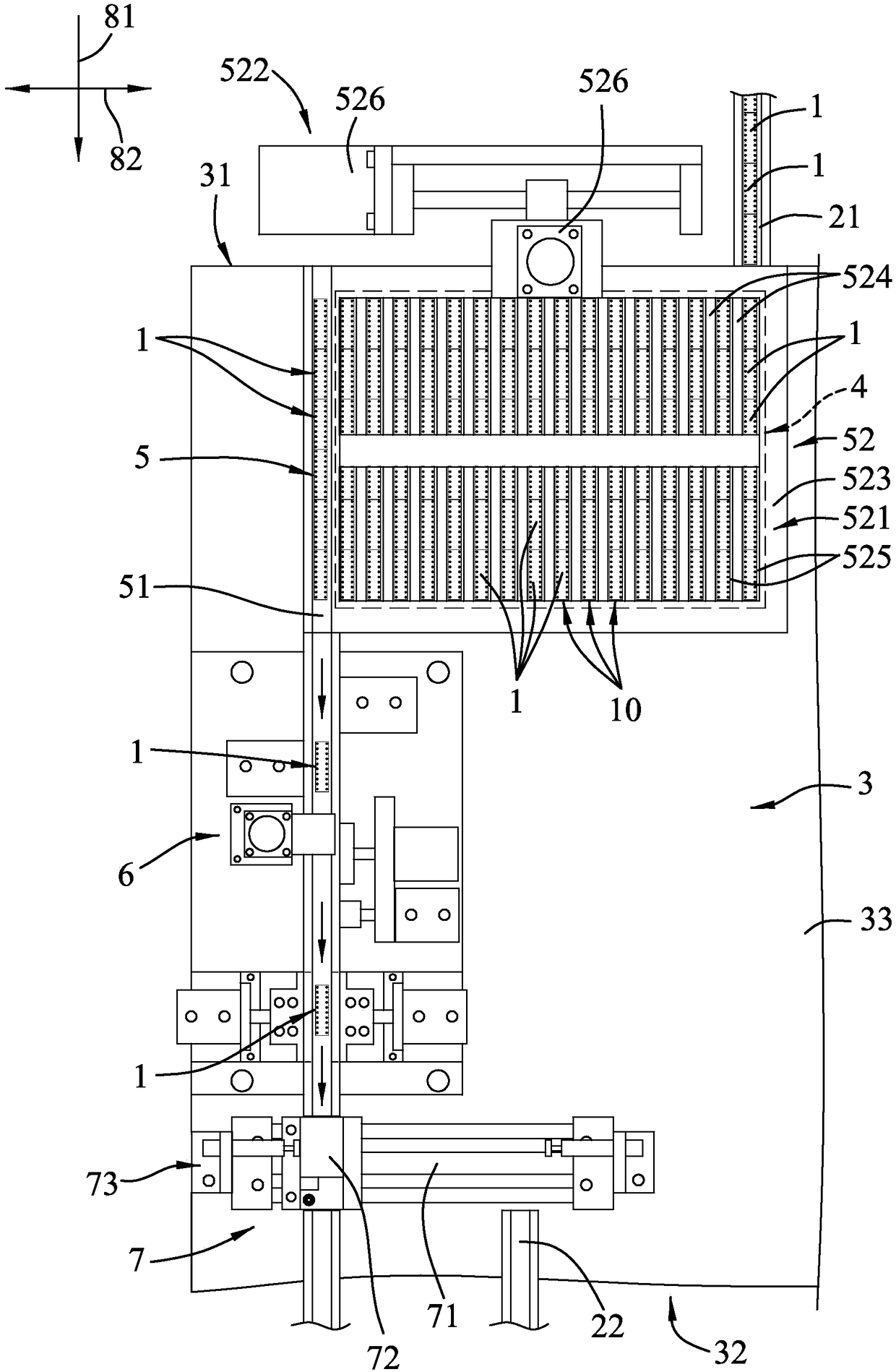

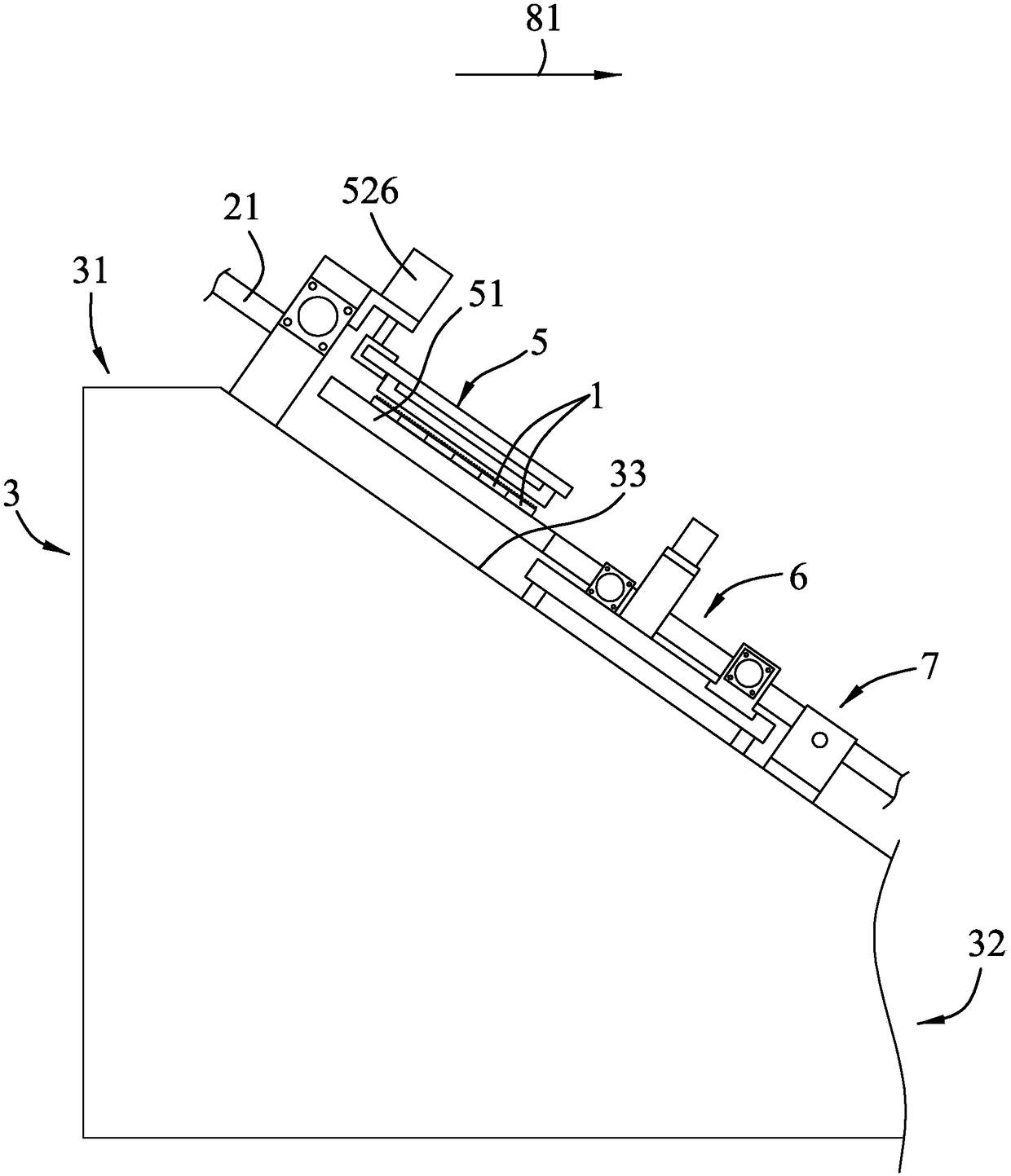

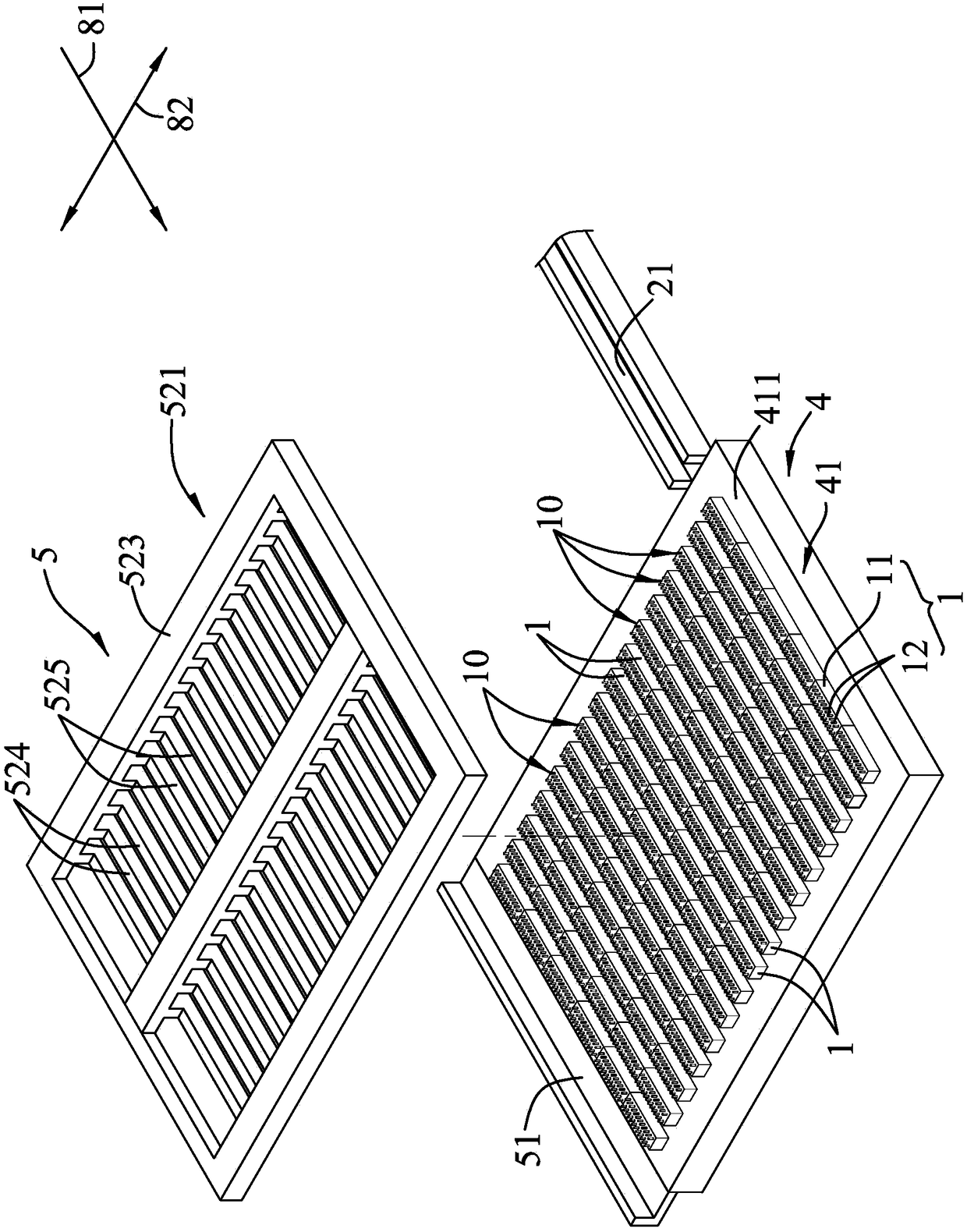

[0019] refer to Figure 1~4 , an embodiment of the electronic component detection device of the present invention is used to detect at least one electronic component 1. This embodiment takes the detection and delivery of several electronic components 1 as an example. Each electronic component 1 includes a body 11, and several Pins 12 located on the body 11 . And the upstream of the detection device is connected with a feeding channel 21 for the electronic component 1 to be transported from. The detection device of this embodiment includes a carrier 3 , and a heating unit 4 , a transport unit 5 , a detection unit 6 and a screening unit 7 installed on the carrier 3 .

[0020] The platform 3 includes an upstream side 31 and a downstream side 32 opposite to each other, and a mounting surface 33 facing upward and gradually sloping downward from the upstream side 31 to the downstream side 32 . The heating unit 4 , the transmission unit 5 , the detection unit 6 and the screening un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com