Biometric chip module packaging device and packaging method therefor

A chip module and packaging equipment technology, applied in the field of biometric chip module packaging equipment and its packaging, can solve the problems of reducing production line utilization rate, increasing packaging operation time, and spending a lot of time, so as to improve operation efficiency and increase utilization The effect of high efficiency and smooth operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

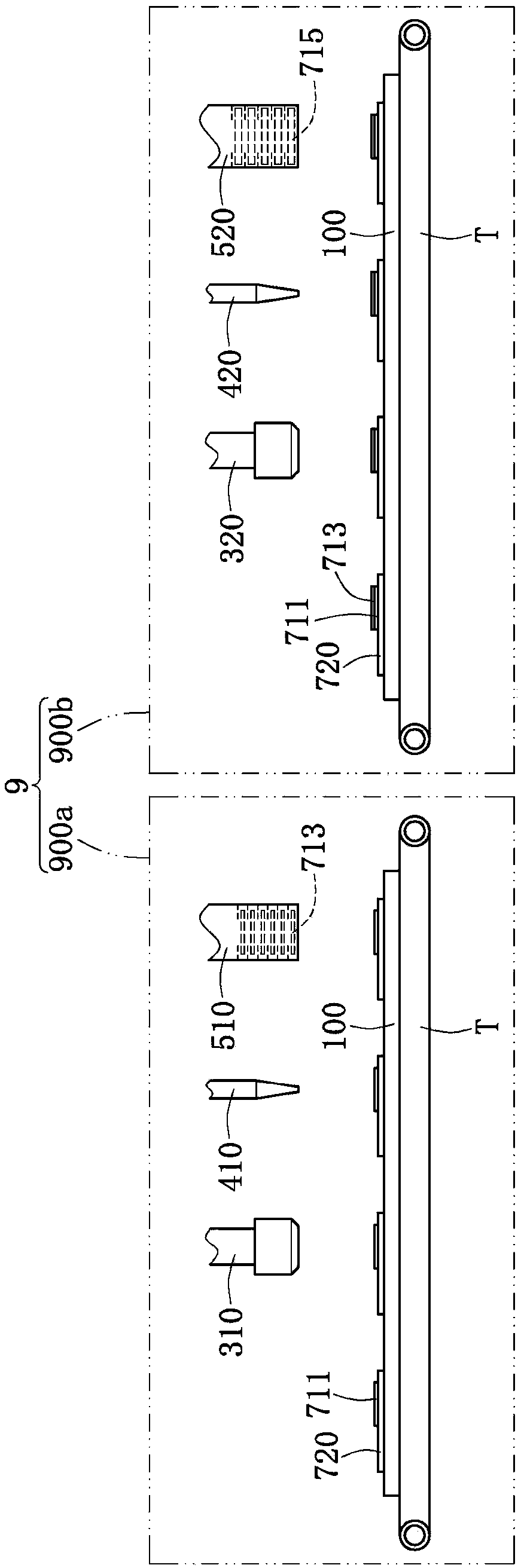

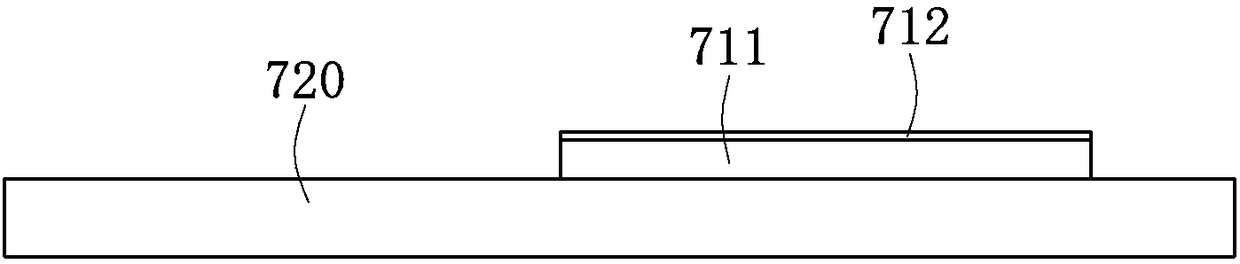

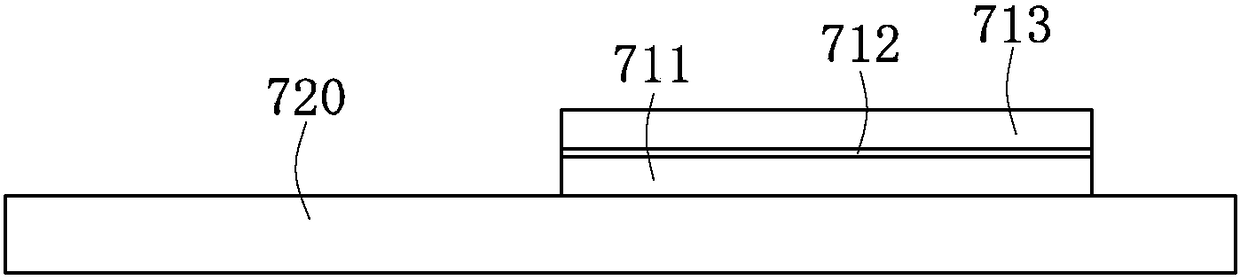

[0019] figure 1 It is a schematic diagram of an embodiment of the biometric chip module packaging device of the present invention. The biometric chip module packaging equipment 9 provides a first operation station 900a and a second operation station 900b. The first operating station 900a has a flat carrier plate 100 for placing a plurality of biometric chip modules to be assembled. The carrier board 100 is transported to the first operation station 900a by a conveyor belt T. Referring to FIG. The first operating station 900 a provides a first image recognition unit 310 located above the carrier board 100 . The first image recognition unit 310 can move in multiple axes, so that the first image recognition unit 310 can be moved to any corner of the carrier board 100 to sequentially acquire multiple circuit boards 720 and biometric chips on the carrier board 100 Step 711 forms an image of the biometric chip module to be assembled, and transmits the acquired image to a computin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com