Riveting worktable

A workbench and riveting technology, applied in the field of riveting, can solve the problems of affecting the yield rate of the radiator, affecting the heat dissipation effect, easy deformation, etc., to achieve the effects of stable and reliable quality, improved production efficiency, and safe production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

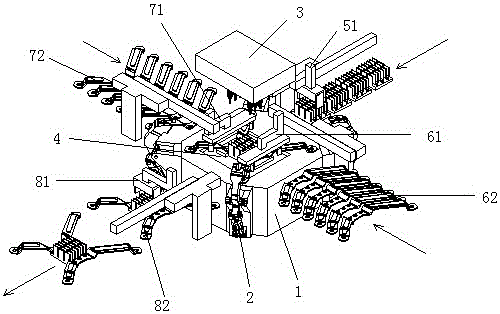

[0021] like Figure 1-3 As shown, the present application discloses a riveting workbench, including a workbench, a locking and positioning device, an upper mold, a lower mold, a feeding device, a first feeding device, a second feeding device and a feeding device; the upper The feeding device and the unloading device are relatively arranged on both sides of the workbench; the first feeding device and the second feeding device are thought to be arranged on the other two sides of the workbench; the locking and positioning devices are respectively arranged on the feeding device and the second feeding device Between two of the first feeding device, the second feeding device and the unloading device.

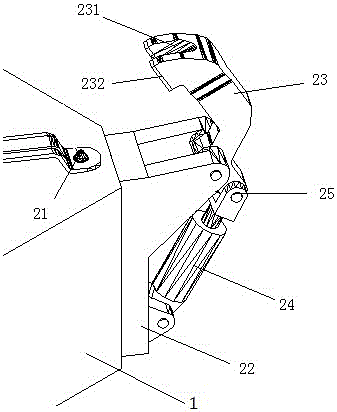

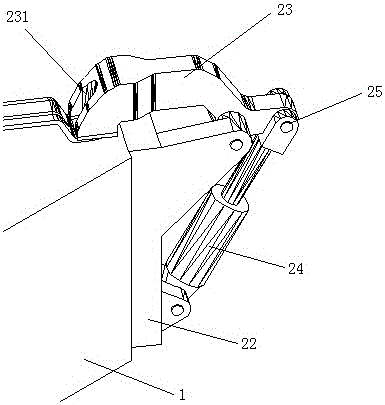

[0022] The locking and positioning device includes a positioning pin fixed on the workbench, a support seat fixed on the side of the workbench, a mechanical arm and a cylinder; the telescopic end of the cylinder is connected to the mechanical arm through a movable shaft, and the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com