2+2 cavity ice-cream box and cover stacking mold

An ice cream box and mold mold technology is applied in the field of 2+2-cavity ice cream boxes and cover mold molds, which can solve the problems of low production efficiency, affecting the quality of box products, damage, etc. The quality of the box product and the effect of reducing the tightening force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

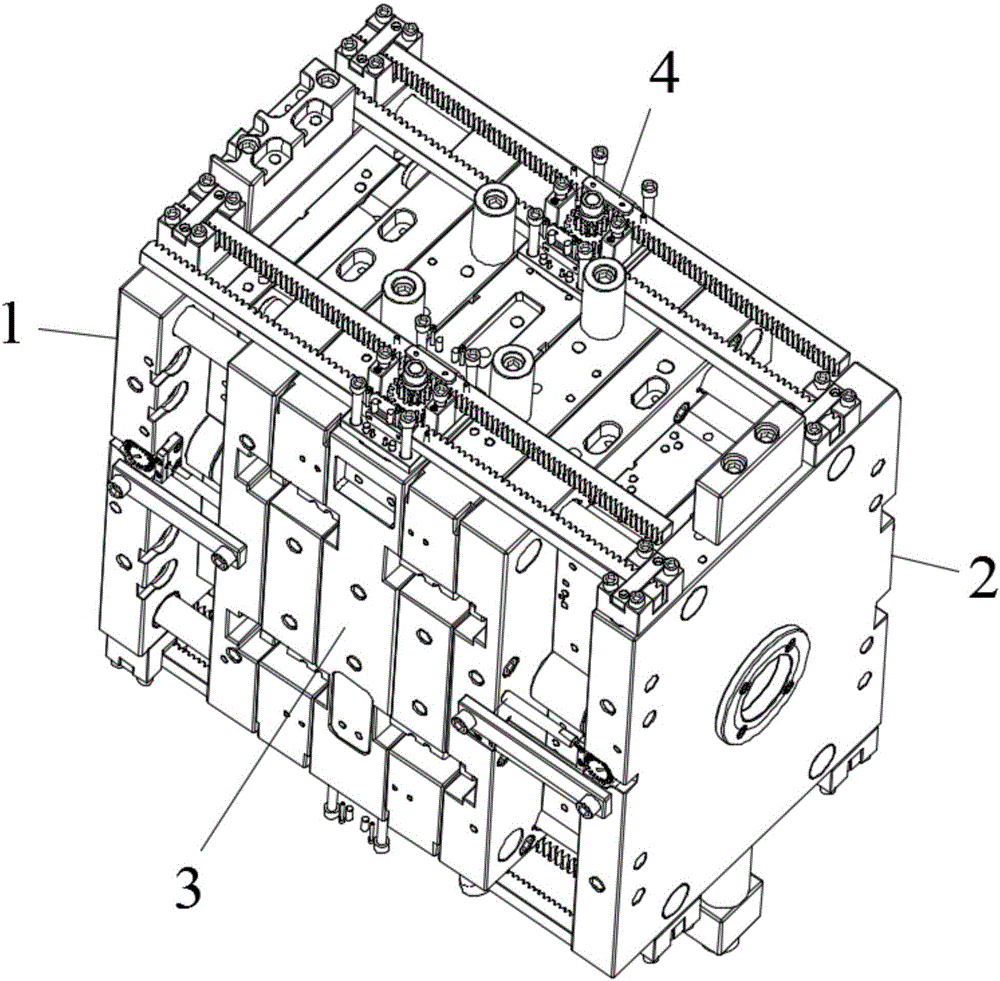

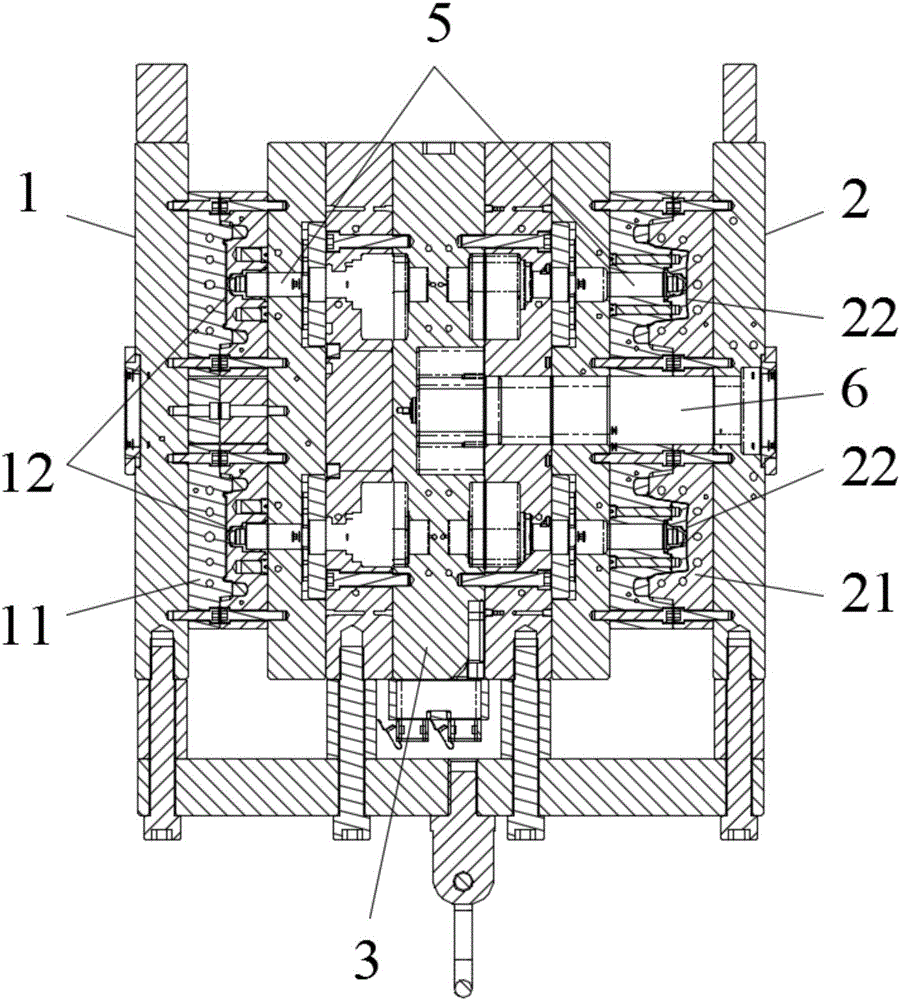

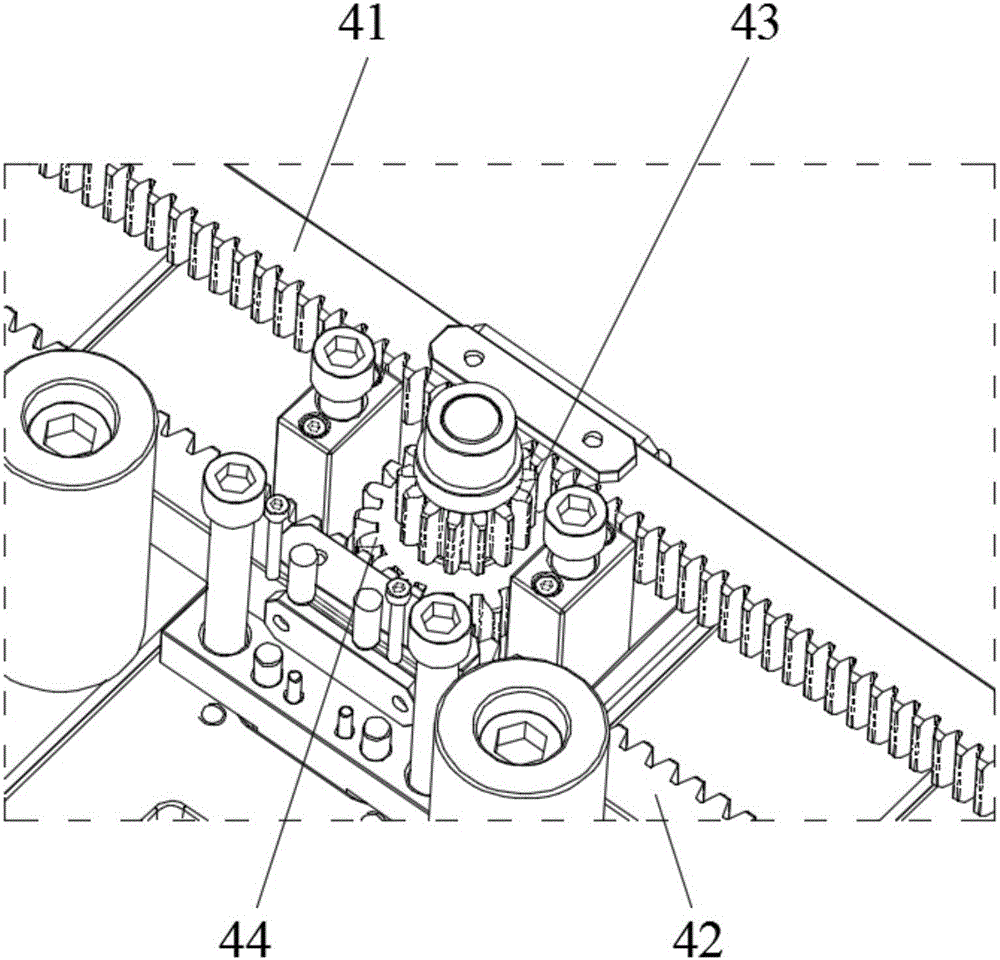

[0014] Such as Figure 1 to Figure 4 As shown, the 2+2-cavity ice cream box and cover stack mold includes a left movable mold 1, a right static mold 2, a middle mold 3, a differential mold opening mechanism 4, a glue injection nozzle 5 and a ejector pin 6; The upper half and the lower half of the left movable mold 1 are respectively provided with a cover forming core 11; the cover forming core 11 is provided with a cover cavity 12; the upper half and the lower half of the right movable mold 2 Each part is provided with a box forming mold core 21; the box forming mold core 21 is provided with a box cavity 22; the differential mold opening mechanism 4 is arranged on the middle mold 3; the differential mold opening mechanism 4 includes static Die rack 42, movable die rack 41, large gear 44 and pinion 43 coaxially fixed on the middle die; one end of said static die rack 42 is fixed with the right static die 2; said movable die rack One end of 41 is fixed to the left movable mold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com