Windshield packaging workbench

A workbench and windshield technology, applied in the field of windshield packaging workbench and workbench, can solve the problems of waste of human resources and low packaging efficiency, and achieve the effect of reducing production cost, easy maintenance and constant gear ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

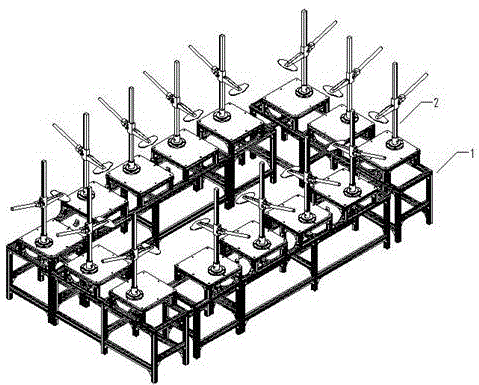

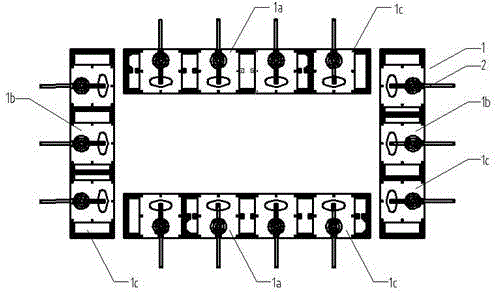

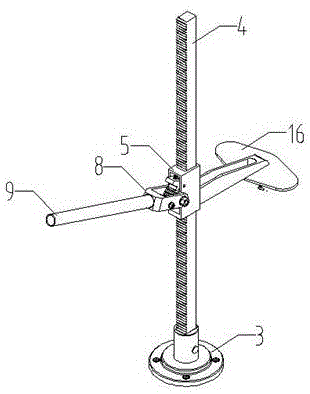

[0027] Example: such as Figure 1-7 As shown, a windshield packaging workbench of the present invention includes a workbench 1 and a pressing mechanism 2 installed on the top of the workbench 1. The pressing mechanism 2 includes a base 3, and a rack 4 is sleeved in the base 3 and The rack 4 is covered with a connecting piece 5, the connecting piece 5 is provided with a gear 6, the gear 6 is connected to the wheel frame 8 through the bolt 7 and the wheel frame 8 is connected to the pressure bar 9, and the gear 6 is connected to the Pull 10 and limit block 11, described pull 10 is connected connector 5 by spring 12, described limit block 11 is provided with cylindrical pin 12, is provided with the first torsion spring 14 and the second in the described wheel frame 8. A torsion spring 15 , the other end of the connecting piece 5 is connected to the slider welding piece 16 .

[0028] The workbench 1 is divided into independent three-position workbench 1a, two-position workbench 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com