Cap supporting device of capping machine

A capping machine and fastener technology, applied in the field of capping devices for capping machines, can solve problems such as affecting drug safety, affecting production cycle, increasing capping devices, etc., to avoid the frequency of environmental pollution and reduce production and operation costs , Improve the effect of product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

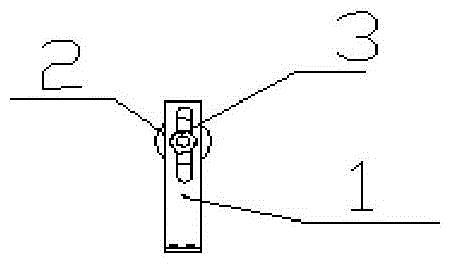

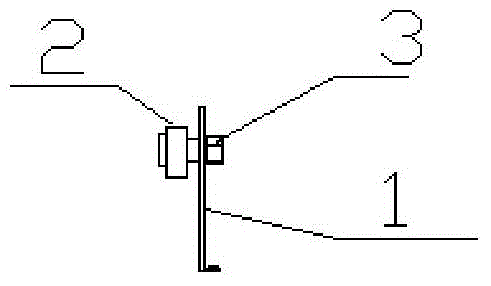

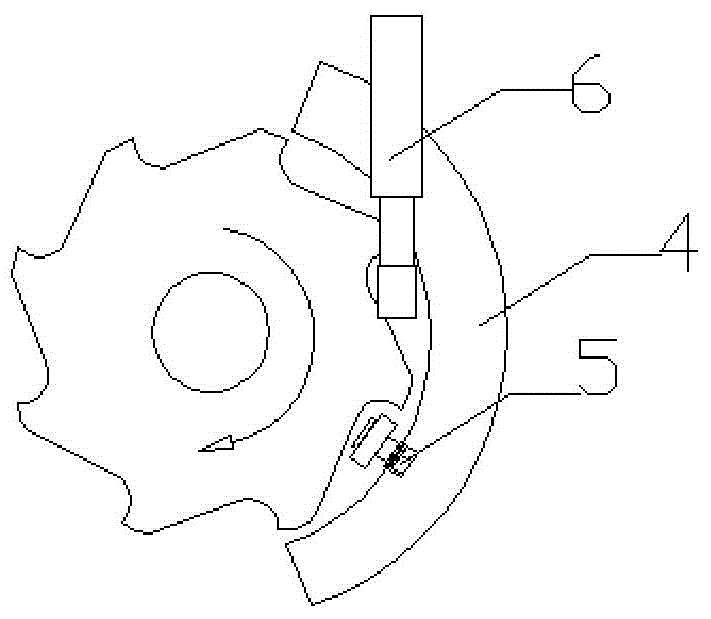

[0024] Below in conjunction with accompanying drawing, the present invention will be further described, see appendix figure 1 , the whole cap supporting device 5 is fixed on the capping machine fence 4 through the bracket 1, the bracket 1 is L-shaped, the axial direction of the bracket 1 is provided with an elliptical hole, and the reinforcement 3 is connected with the bearing 2 through the elliptical hole of the bracket, The fastener includes nuts and bolts, and the height of the cover support device can be adjusted through the oval hole. For better connection between the reinforcement 3 and the bearing 2, a washer can be provided between the reinforcement 3 and the bracket 1 .

[0025] Table 1: Verification data of capping failure rate without adding capping device

[0026] batch number

packing date

Bad capping

14020508

2014.04.04

110

14020608

2014.04.11

146

14030108

2014.04.24

171

14030208

2014.04.27 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com