Belt double-tensioning transmission device for clothes dryer and clothes dryer

A transmission device and tensioning device technology, applied in the field of clothes dryers, can solve the problems of unreliable forward and reverse transmission of the dryer drum, failure to provide transmission, and decreased transmission force, so as to shorten the drying time of clothes and ensure drying Uniformity, effect of preventing clothes from tangling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

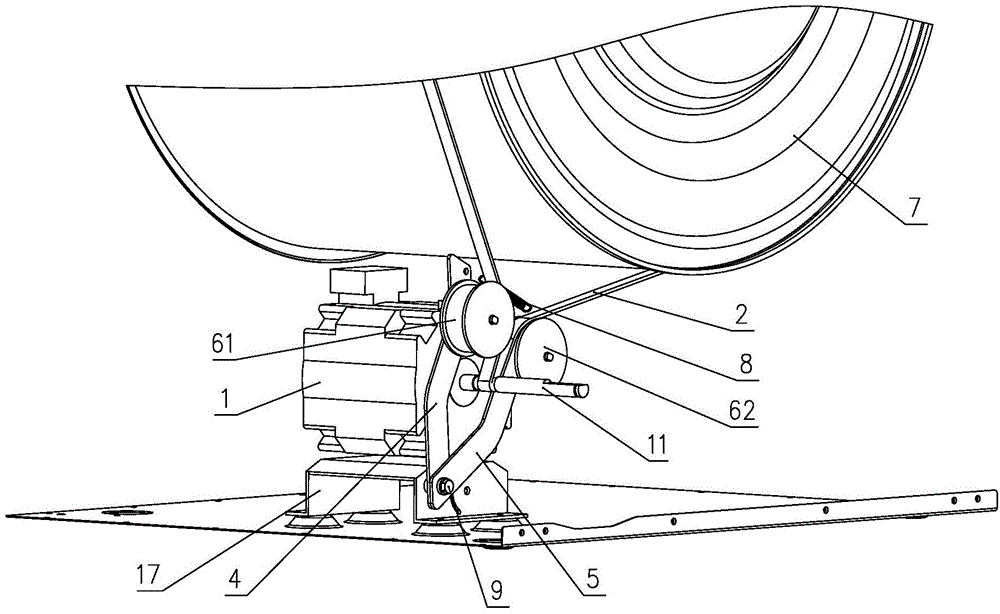

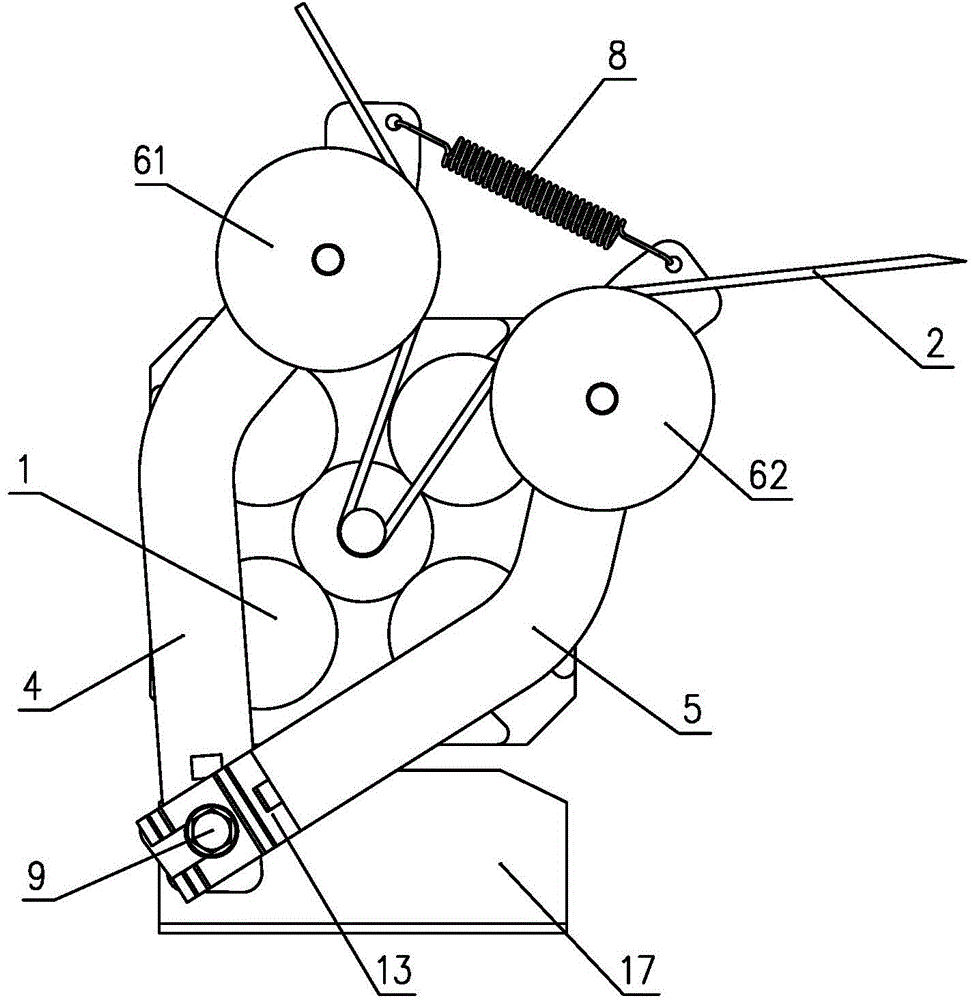

[0041] This embodiment provides a double tension transmission device for clothes dryer belts, such as Figure 2 to Figure 6 As shown, it includes a motor 1, a belt 2 wound around the motor transmission shaft 11, and a belt tensioner. The belt tensioning device has two tensioning pulleys, which are respectively arranged on both sides of the motor transmission shaft 11 on the transmission path of the belt 2, so that when the motor 1 rotates forward and reverse, the belt tensioning device can both rotate the belt 2 Tension is performed to prevent belt 2 from slipping.

[0042] The belt tensioning device comprises a first tensioning arm 4 and a second tensioning arm 5 which are passed through the same fixed shaft 3, a first tensioning pulley 61 is installed on the free end of the first tensioning arm 4, and a second tensioning wheel 61 is installed on the free end of the first tensioning arm 4. The free end of the arm 5 is fitted with a second tensioning wheel 62 . The first ten...

Embodiment 2

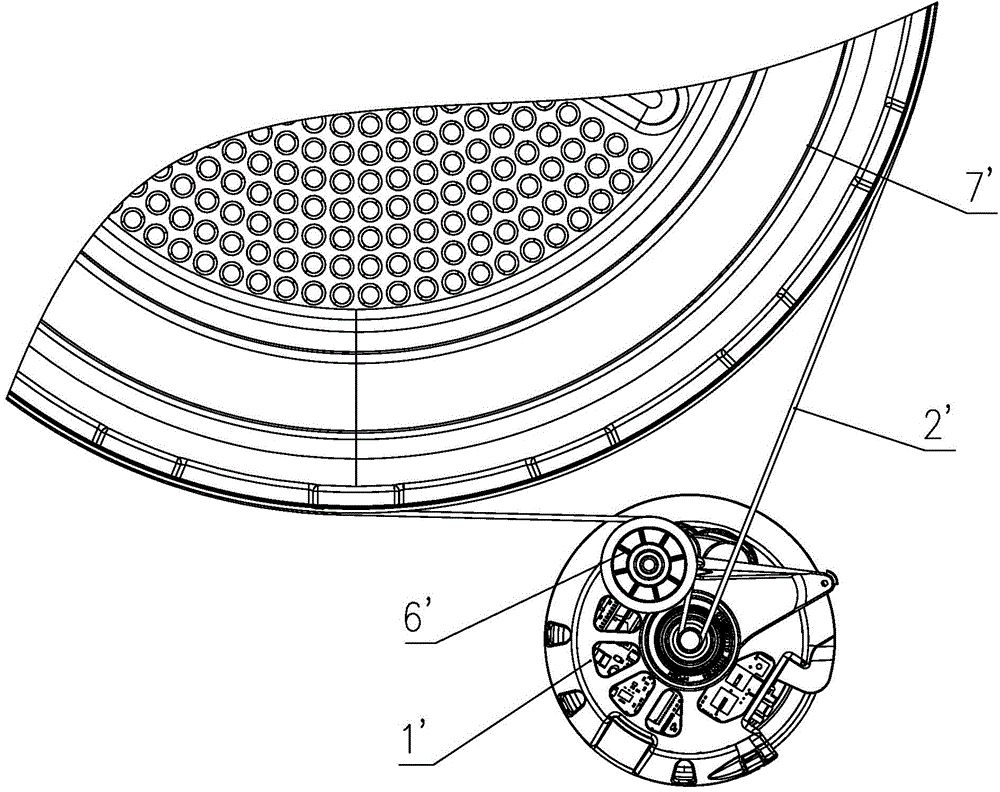

[0051] This embodiment provides a double tension transmission device for clothes dryer belts, such as Figure 10 As shown, its structure is basically the same as that of Embodiment 1, including a motor 1, a belt 2 wound on the motor transmission shaft 1, and a belt tensioning device. The belt tensioning device comprises a first tensioning arm 4 and a second tensioning arm 5, the free end of the first tensioning arm 4 is equipped with a first tensioning pulley 61, and the free end of the second tensioning arm 5 is equipped with a second Tensioner 62. The first tensioning arm 4 and the second tensioning arm 5 are connected by a spring 8 .

[0052] The difference is that the first tensioning arm 4 and the second tensioning arm 5 are threaded on different fixed shafts, which can effectively prevent the movement interference of the two tensioning arms and further improve the reliability of the transmission.

Embodiment 3

[0054] This embodiment provides a clothes dryer, which includes a drum and the dryer belt double-tensioning transmission device described in Embodiment 1 or 2, and the drum is driven to rotate by the belt of the clothes dryer belt double-tensioning transmission device. This enables the drum to perform reliable positive and negative rotation, ensuring uniform drying of the clothes, shortening the drying time of the clothes, and preventing the clothes from being entangled.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap