A lattice type lightning rod of herringbone column substation structure

A technology of substation structure and lightning rod, which is applied in the direction of circuits, electrical components, corona discharge devices, etc., can solve the problems of easy fatigue damage and connection of lightning rods, unreliability, etc., and achieve improved connection reliability, prevention of falling off, and high safety performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

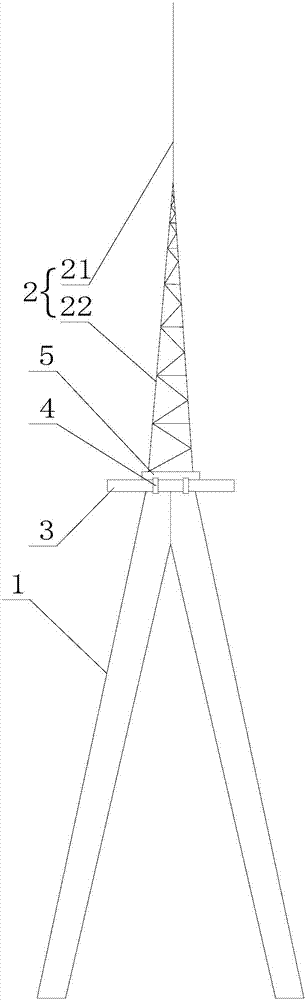

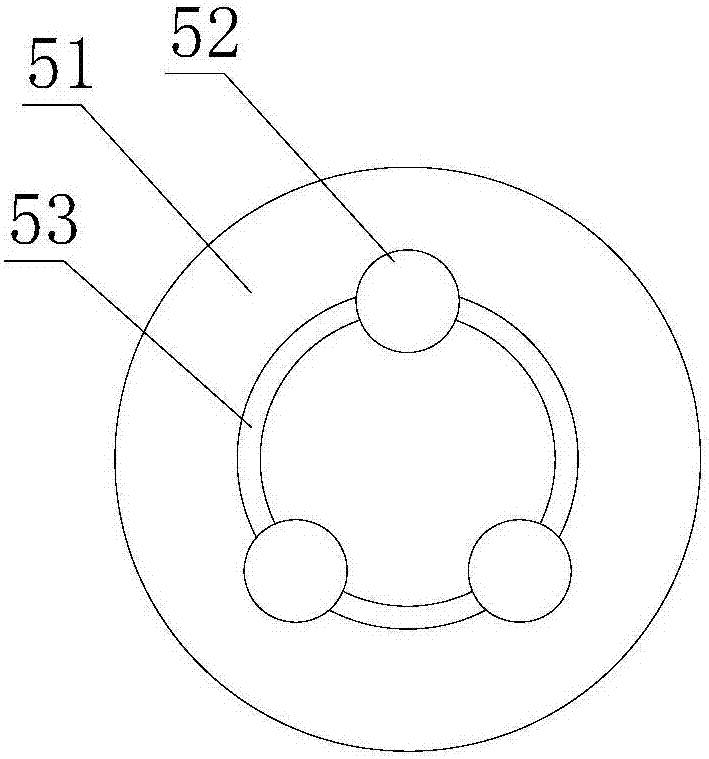

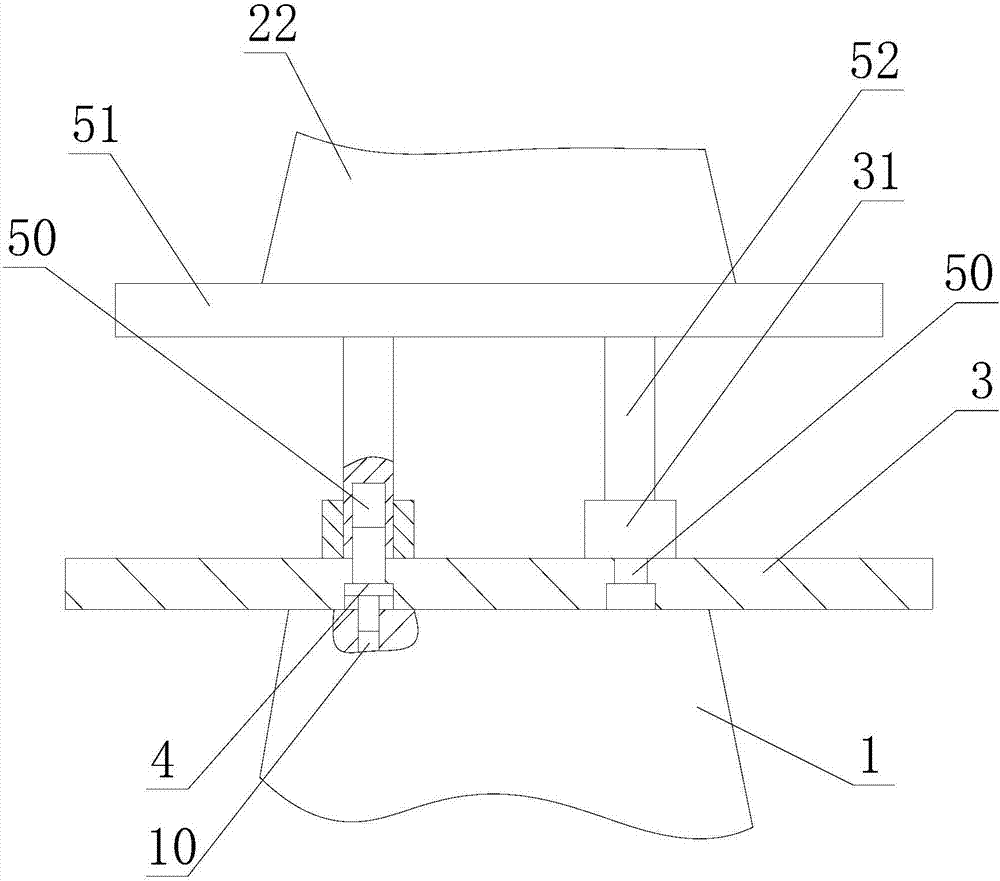

[0026] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, a herringbone column substation frame lattice lightning rod includes a herringbone column 1 and a lightning rod 2. The lightning rod 2 includes a lightning rod tip 21 and a main carrier 22 whose main body is a lattice structure. The lightning rod tip 21 is arranged on the main carrier At the top of the body 22, the main supporting body 22 adopts a round steel lattice structure, which is formed by intersecting welding between the web and each main chord, and the bottom end of the main supporting body 22 is connected with a connecting plate connected with the herringbone column 1 3. The connecting plate 3 is fixedly connected to the top of the herringbone column 1 through the fastener 4, and the bottom end of the main carrier 22 is provided with a fixed part 5 for fixing the connecting plate 3, and the fastener 4 is connected to the fixed part 5. The fixed part is connected with the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com