Self-vibrating type material clearing tube device for housing stretching-out section of material-pushing centrifugal machine

A centrifuge and cleaning pipe technology, applied in the field of centrifuges, can solve problems such as material blockage in the discharge pipe and centrifuge failure, and achieve the effects of simple structure, guaranteed safety, and low overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

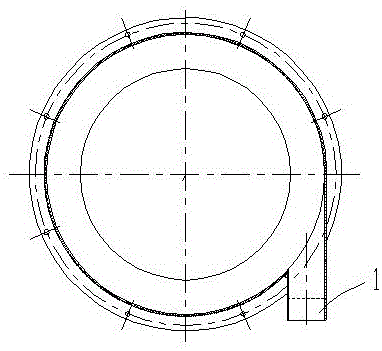

[0021] see figure 1 , The present embodiment is a self-vibration cleaning pipe device for the extension section of the pusher centrifuge casing, which is designed on the extension section of the casing when the double-stage pusher centrifuge uses a closed circular tube collection tank.

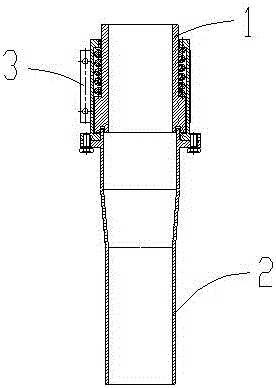

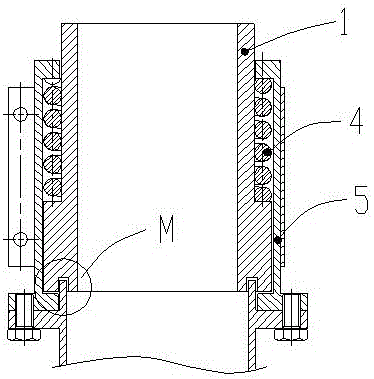

[0022] Install the discharge pipe 2 through the intermediate transition body on the extension section 1 of the casing, such as figure 2 As shown, the inner hole of the discharge pipe 2 has a section of taper, that is, the discharge pipe 2 can be divided into three sections according to the inner hole: the first section is a straight pipe section whose aperture is larger than the inner hole of the casing extension section 1, and the second section The first section is the taper section connected with the straight pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com