An inner plug shaping mechanism and a mandrel installation device with the mechanism

A technology for installing devices and inner plugs, which is applied to hand-held tools and manufacturing tools, can solve the problems of time-consuming, labor-intensive, low production efficiency, and cumbersome operation methods, and achieve the effects of simple operation, improved production efficiency, and improved plastic surgery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] see Figure 4-5 , the inner plug shaping mechanism described in the present application is used to arrange and output the inner plugs of the electric heating mosquito coil in the same direction, that is, to make the axes of the output inner plugs parallel to each other.

[0031] The inner plug shaping mechanism includes a base 101 and an inner plug shaping cavity 102 arranged at one end of the base 101. A solenoid valve 103 and a shrapnel 104 fixed by the outer ring of the solenoid valve 103 are installed in the base 101. 1. A bracket connected to the electromagnetic valve through bolts and a connecting nut 105, the bracket is fixedly connected to the inner plug shaping cavity 102 through the connecting nut 105, and the working strength of the electromagnetic valve 103 is controlled by changing the energization frequency of the electromagnetic valve to control the working strength of the electromagnetic valve 103. Describe the deformation of the shrapnel 104 connected t...

Embodiment 2

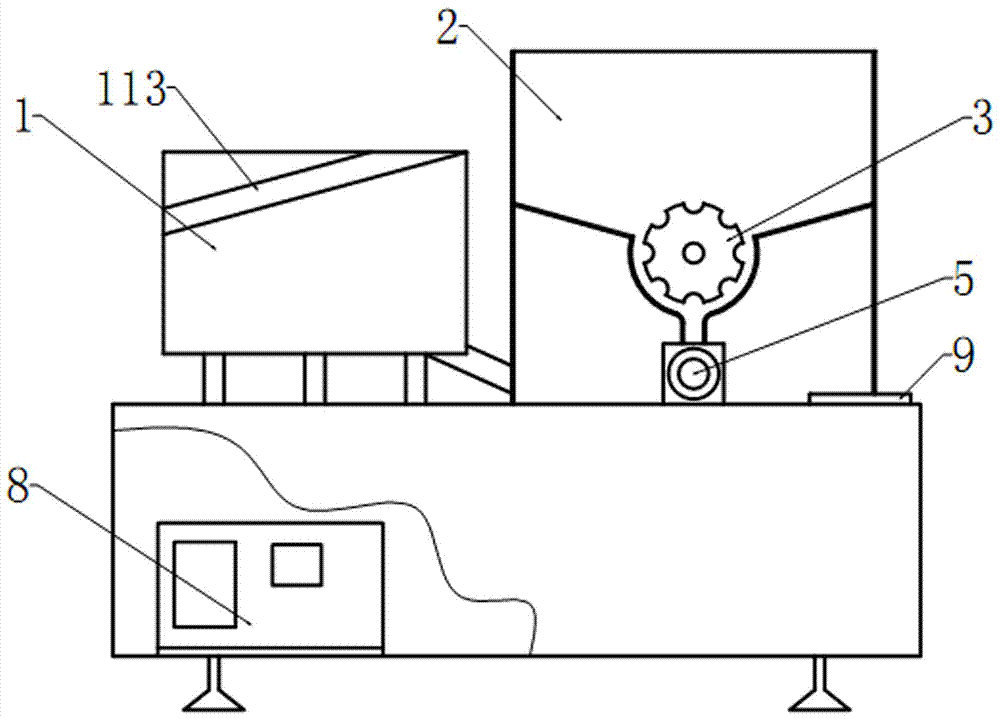

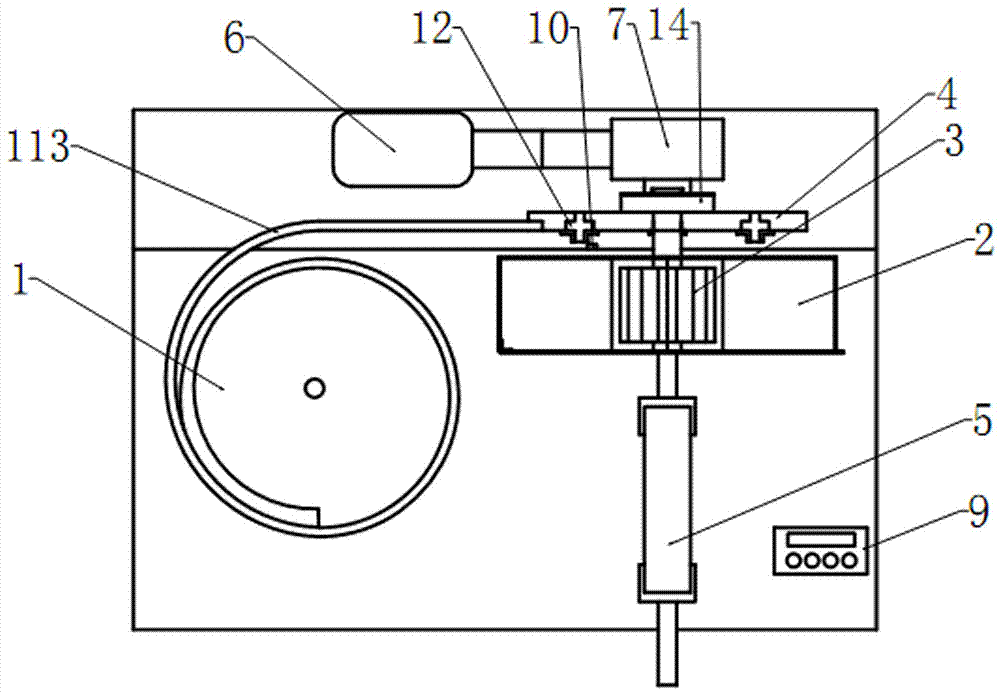

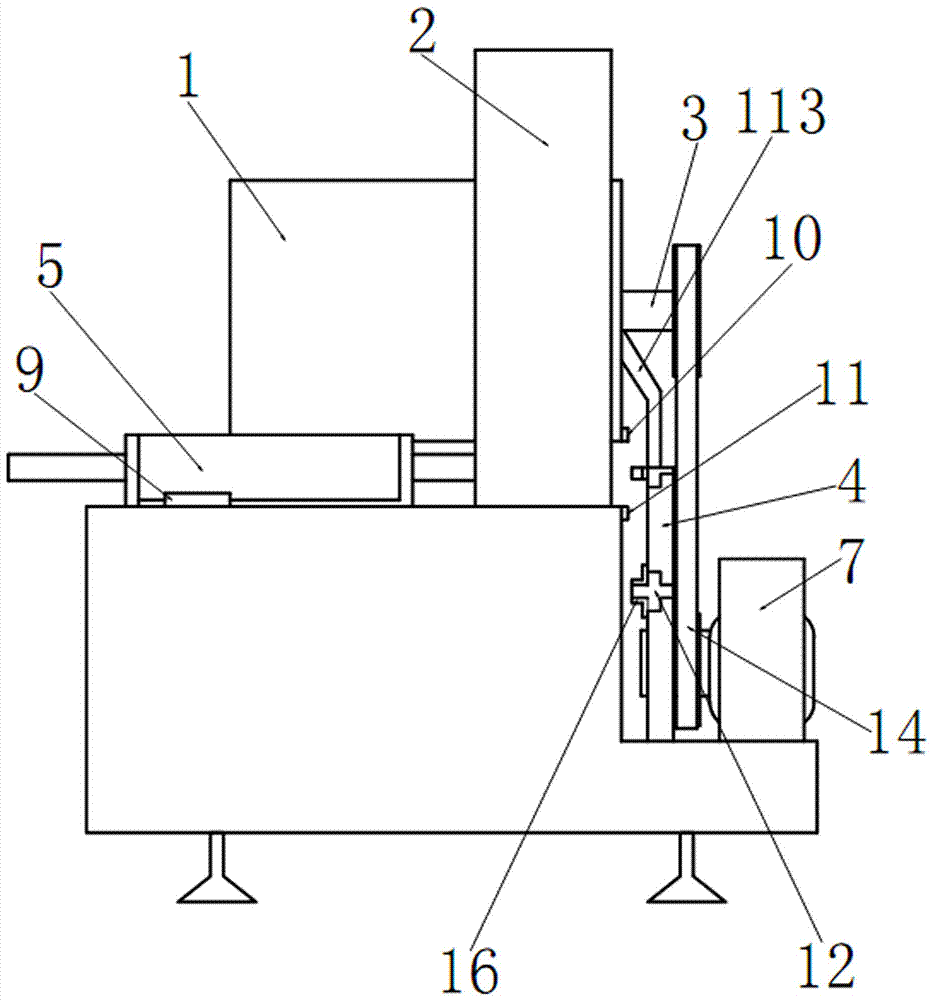

[0038] see Figure 1-5 , the mandrel installation device shown in the preferred embodiment of the present invention includes an inner plug shaping mechanism 1 , an inner plug fixing mechanism, a mandrel output mechanism 2 , a driving mechanism 5 , and a control system 8 . The structure of the inner plug shaping mechanism 1 is consistent with the structure of the inner plug shaping mechanism shown in Embodiment 1, and will not be repeated here.

[0039] The inner plug shaping mechanism 1 also includes an output guide rail 113 connected with the inner plug climbing track 106, and the output guide rail 113 is connected with the inner plug fixing mechanism for outputting to the inner plug fixing mechanism. Nesse. The arrangement according to the predetermined direction is to facilitate the axial direction of any single inner plug entering the inner plug fixing mechanism from the output guide rail 113 to be parallel to the direction in which the drive mechanism 5 drives the mandre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com