Framework used for containing iron tower accessories

A technology for accessories and iron towers, which is applied in the field of auxiliary tools for iron tower accessories processing, which can solve the problems of messy construction sites, affecting construction efficiency, random placement of boxes, etc., and achieves the effects of saving space, low cost, and facilitating popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

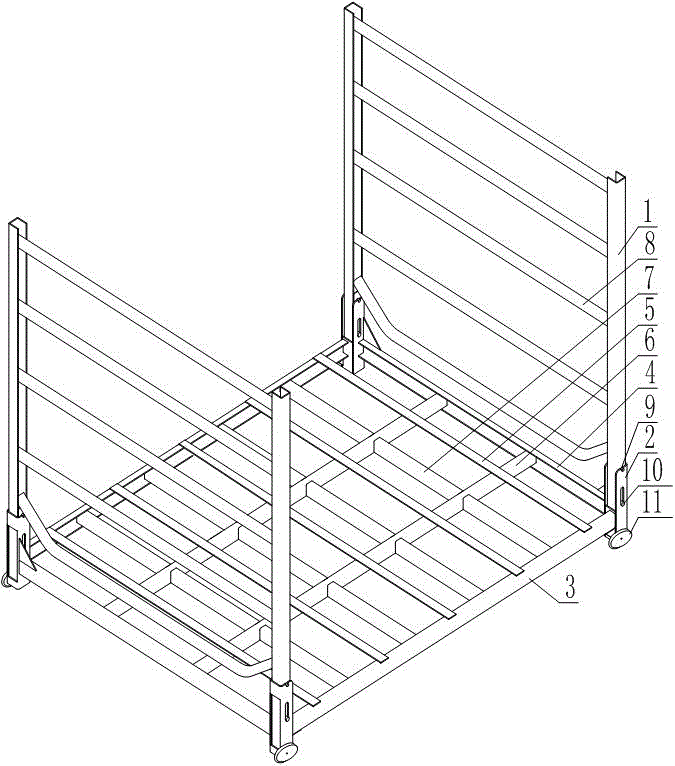

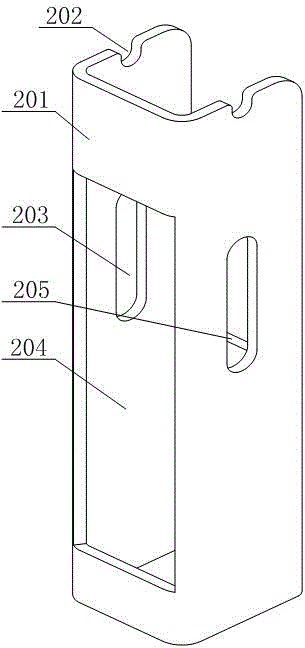

[0020] Such as figure 1 As shown, a structure for shelving iron tower accessories, including a vertical plate 1, a connecting piece 2, a horizontal frame plate 3, a longitudinal frame plate 4, a support plate 5, a limit plate 8, a first support column 9, a second support Columns 10 and rollers 11, wherein, in order to facilitate the application of this embodiment, the vertical plate 1, the horizontal frame plate 3 and the vertical frame plate 4 of this embodiment are all made of channel steel. The quantity of the transverse frame board 3 and the longitudinal frame board 4 of the present embodiment is two pieces, wherein, the two horizontal frame boards 3 are arranged horizontally and horizontally and both are spaced at a certain distance in the longitudinal direction, and the two vertical frame boards 4 are vertically arranged. Set horizontally with a certain distance between them in the horizontal direction. In this embodiment, the number of connectors 2 is four, and the fou...

Embodiment 2

[0026] This embodiment makes the following further limitations on the basis of embodiment 1: this embodiment also includes a transverse reinforcement plate 6 and a longitudinal reinforcement plate 7, wherein the number of the transverse reinforcement plate 6 and the longitudinal reinforcement plate 7 is multiple. The horizontal heights of the transverse reinforcing plate 6 and the longitudinal reinforcing plate 7 are all lower than the level of the support plate 5, and a plurality of transverse reinforcing plates 6 are arranged horizontally and arranged at equal intervals in the longitudinal direction, and the two ends of each transverse reinforcing plate 6 They are respectively connected to two longitudinal frame plates 4, and the plurality of longitudinal reinforcing plates 7 are vertically and horizontally arranged, and each longitudinal reinforcing plate 7 passes through all the transverse reinforcing plates 6 and its two ends are respectively connected to two transverse fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com