A high-speed EMU drainage device

A technology for high-speed EMU and drainage device, which is applied in the directions of transportation and packaging, railway car body parts, railway transportation, etc., can solve the problems such as difficult to achieve lightweight car body, smaller effective volume of drainage cavity, and inability to effectively store wastewater, etc. To achieve the effect of reducing the frequency of cleaning and maintenance, achieving light weight and reducing the overall height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

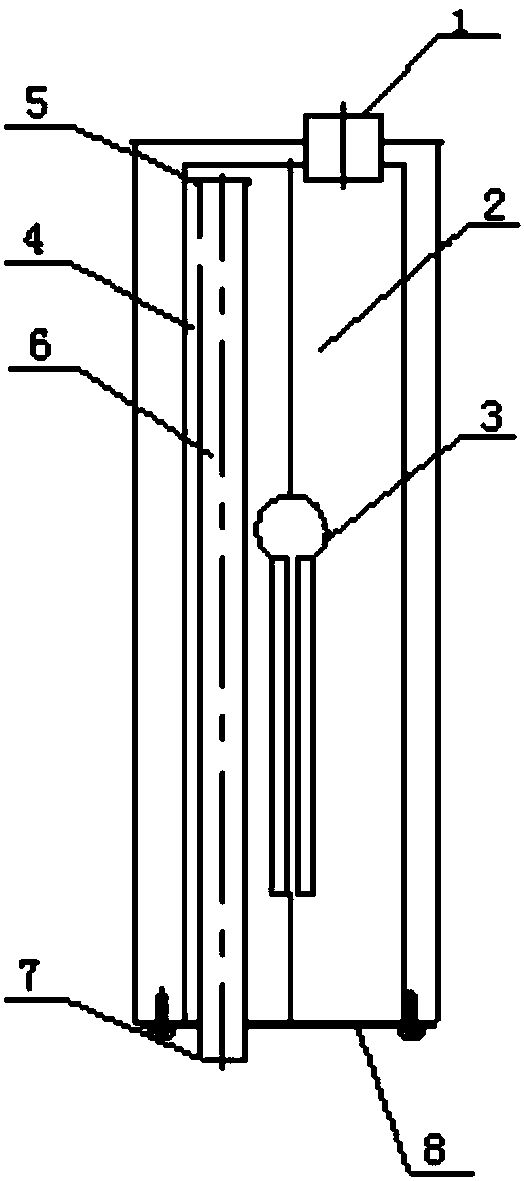

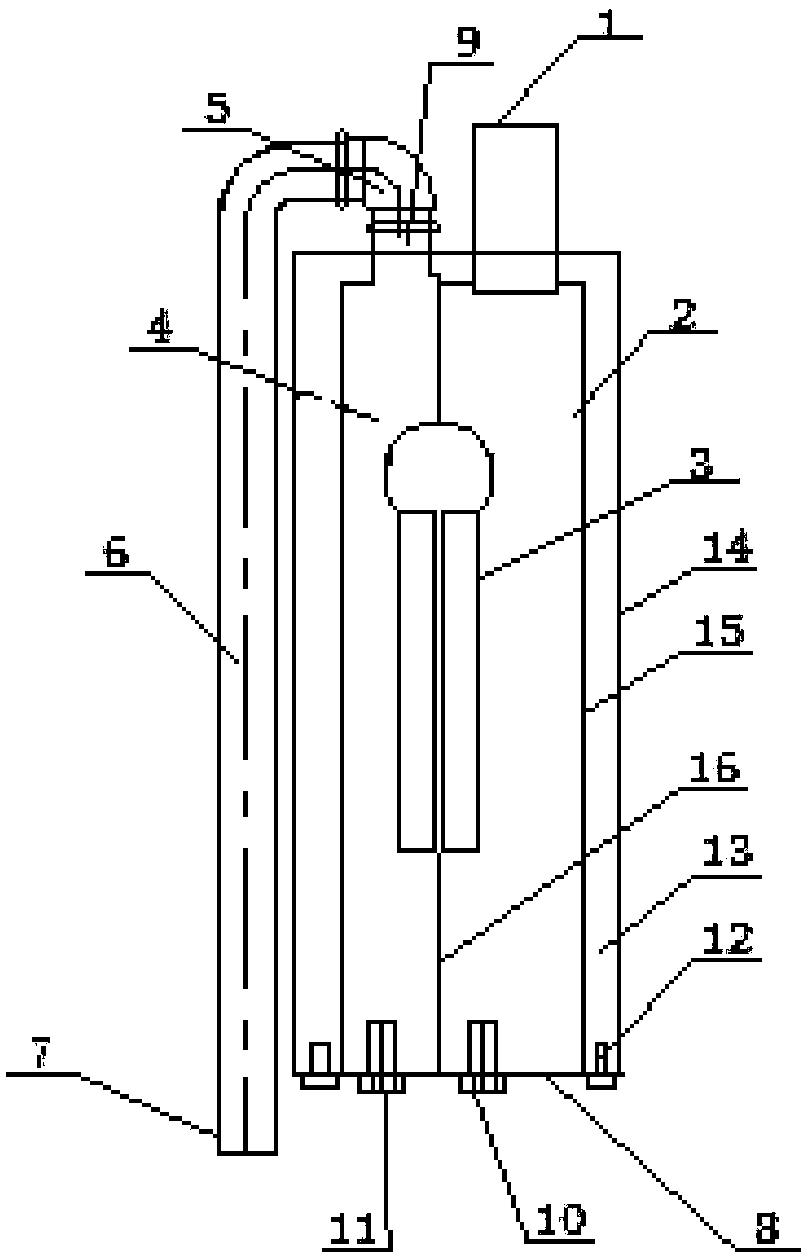

[0018] The present invention provides a high-speed motor car drainage device, including a water collection container and a drainage pipeline 6. The water collection container includes a casing 14 and a cavity 15 inside the casing 14. The inside of the cavity 15 is divided into a drainage cavity 4 and a drainage cavity 4 by a partition 16. The water inlet chamber 2, the siphon tube 3 installed on the partition 16 connects the drainage chamber 4 and the water inlet chamber 2, the top of the water inlet chamber 2 is connected to the water inlet pipe 1, and the top of the drainage chamber 4 is connected to the drainage pipeline through the water inlet pipe interface 9 The drain pipe inlet 5 of 6, the drain pipe 6 is located outside the water collection container, the drain pipe outlet 7 at the end of the drain pipe 6 is located below the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com